High-efficient treatment method for biologically-enhanced coking waste water for biological membrane

A technology of coking wastewater and bioaugmentation, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of coking wastewater that are difficult to treat, and achieve high volume load and dissolved components. High, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

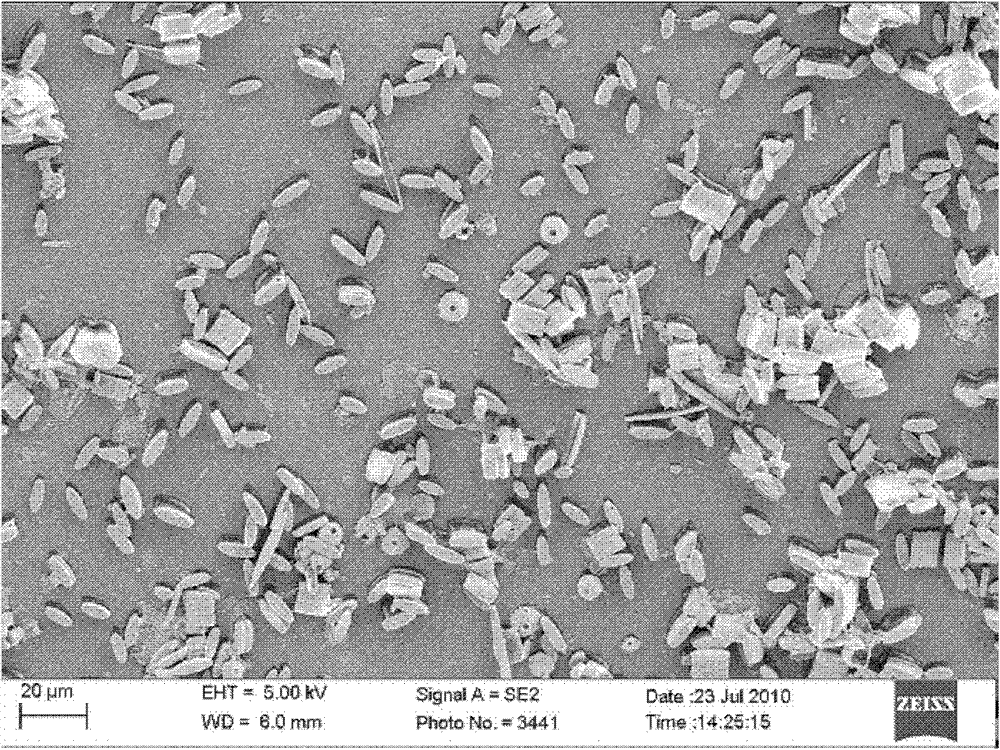

[0031]The high-efficiency treatment method of biofilm bio-enhanced coking wastewater of the present invention comprises an anaerobic biofilter-three-phase aerobic biological circulating fluidized bed coupling process to treat coking wastewater, which is divided into a film-forming period and a formal operation period; in the film-forming period, First, add the membrane support carrier in the anaerobic biological filter-three-phase aerobic biological circulating fluidized bed coupling process reactor, and then add Comamonas testosterone CGMCC No.4630 to hang the film, after the film hanging is completed, the system will Form a unique ecological island system in a specific environment. The specific structure and process of the anaerobic biological filter-three-phase aerobic biological circulating fluidized bed coupling process of the present invention can refer to Chinese patent CN101597125A (because the biochemical process can achieve the expected effect in the three-phase aerob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com