Shielding suspension type pump

A technology of overhanging and shielding pipes, applied in non-variable-capacity pumps, non-displacement pumps, pumps, etc., can solve the problems of inapplicability, difficult maintenance, clogging of self-priming pumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

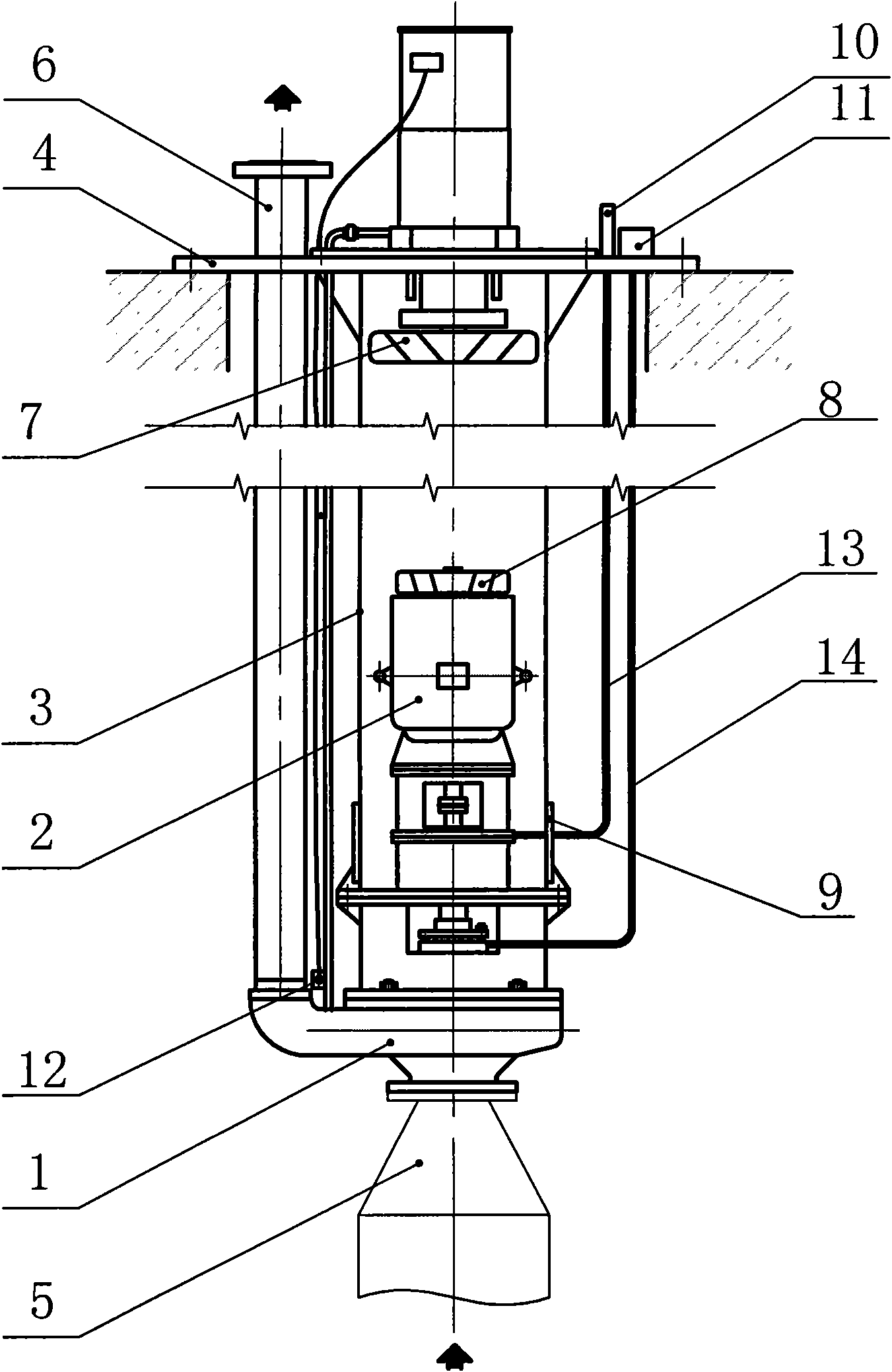

[0019] The shielded suspension pump includes a delivery pump 1, a driving motor 2, a suspension support shielding pipe 3, a suction pipe 5, an output pipe 6, a ventilation system, a lubricating oil pressurized delivery device 10 and a sealing packing pressurized injection device 11.

[0020] Suspended support shielding pipe 3 has upper and lower connecting flanges, the upper end flange is fixed on the support plate 4, the lower end flange hangs and fixes the delivery pump, and the drive motor 2 and the bearing body of the delivery pump 1 are placed on the suspension support shielding pipe 3 Inside, the upper end of the suction pipe 5 is airtightly connected with the inlet of the delivery pump, and its lower end is vertically inserted into the water.

[0021] The lower end of the output pipe 6 is airtightly connected to the outlet of the delivery pump 1 , and its upper end is exposed above the ground, and a liquid level sensor 12 is fixed on the lower part of the output pipe 6 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com