Ventilation and temperature reduction tower of high-temperature workshop

A technology for ventilation, cooling, and high temperature workshops, which is applied in space heating and ventilation, heating methods, lighting and heating equipment, etc. the harmful effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

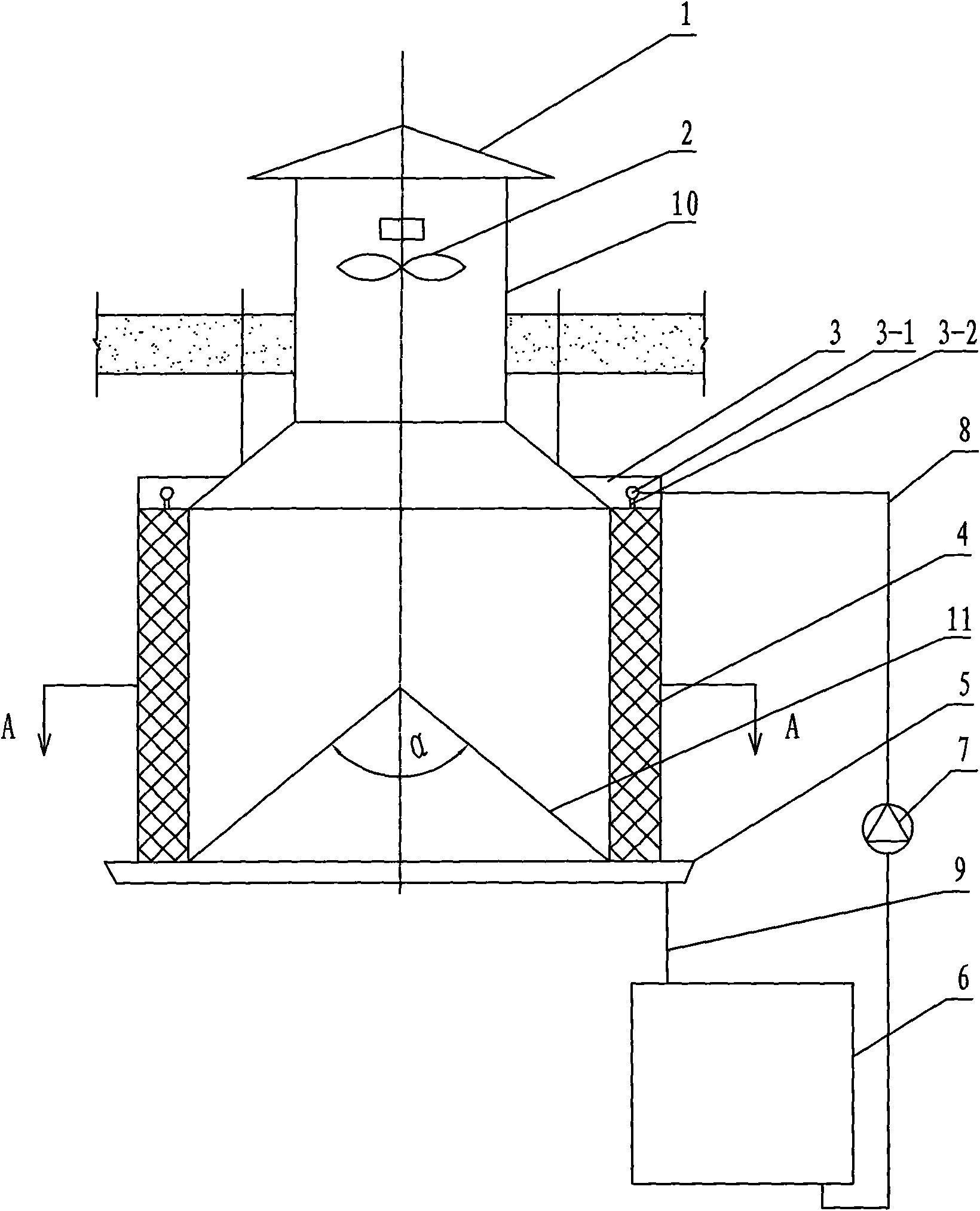

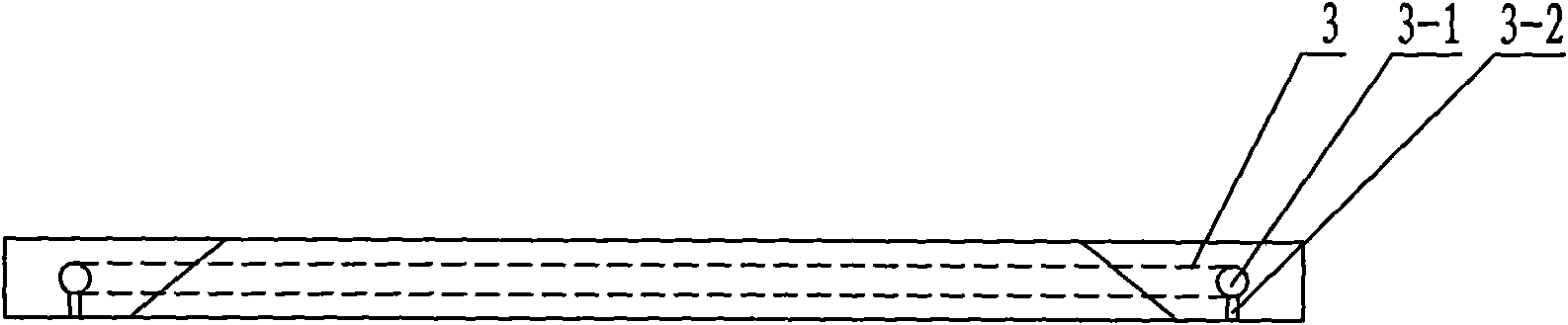

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, a high-temperature workshop ventilation and cooling tower in this embodiment includes a ventilation cap 1, a ventilation fan 2, an air duct 10, a water distribution pan 3, a hollow packing layer 4, a water collection pan 5, a circulating water tank 6, and a circulating water pump 7. The water inlet pipe 8 and the return pipe 9, the ventilation fan 2 is installed in the air duct 10, the upper end of the air duct 10 is installed on the lower end surface of the ventilation cap 1, and the lower end of the air duct 10 is installed in the hollow packing layer 4 On the inner wall of the upper end, the water distribution tray 3 is installed on the upper end surface of the hollow packing layer 4, and an annular groove 3-1 is opened in the water distribution tray 3, and a plurality of cloths are arranged on the lower end surface of the water distribution tray 3. Water holes 3-2, the plurality...

specific Embodiment approach 2

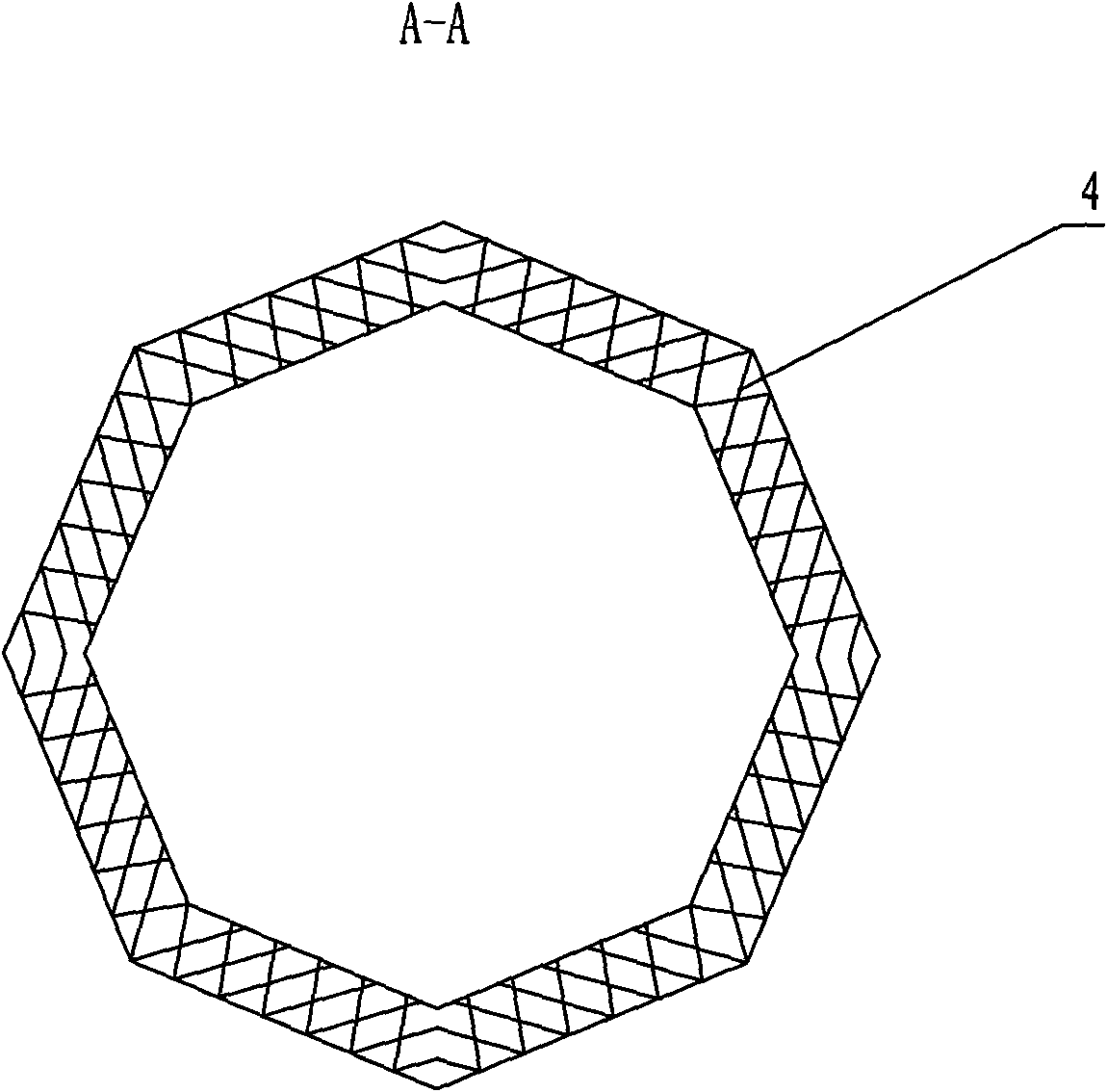

[0008] Specific implementation mode two: combination figure 2 The present embodiment will be described. The cross-sectional shape of the hollow packing layer 4 in the present embodiment is a regular polygon. Such setting facilitates production and processing. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the ventilation and cooling tower of this embodiment is further provided with a conical wind deflector 11, and the conical wind deflector 11 is arranged inside the hollow packing layer 4 and installed on the upper end surface of the water collecting pan 5 . Such setting realizes the guidance of the wind, thus speeding up the ventilation and cooling speed. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com