Backlash converter

A technology of flyback converter and transformer, which is applied in the direction of instruments, adjusting electric variables, converting DC power input to DC power output, etc. It can solve the problems of low switching loss and high switching loss, and reduce conduction loss and cut-off loss , the effect of reducing voltage loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

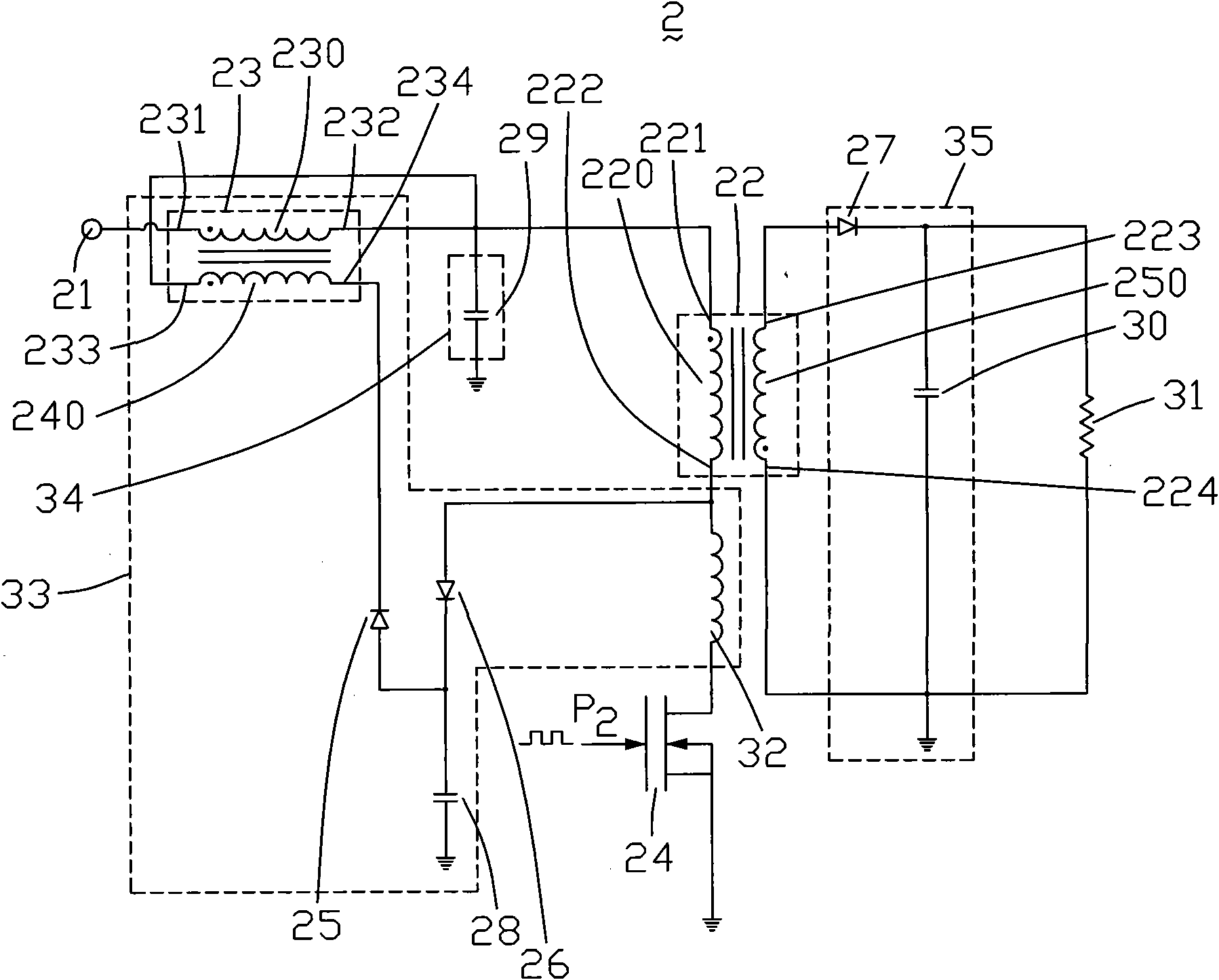

[0017] see figure 2 , is a circuit structure diagram of a preferred embodiment of the flyback converter of the present invention. The flyback converter 2 includes a voltage input terminal 21 , a first transformer 22 , a switch tube 24 , an auxiliary circuit 33 , a filter circuit 34 , a rectification filter circuit 35 and a load 31 . The voltage input terminal 21 is a DC voltage input terminal, and the switch tube 24 is an N-channel enhancement type field effect transistor. The load 31 is a resistor.

[0018] The first transformer 22 includes a first primary winding 220 and a first secondary winding 250 . The first primary winding 220 includes a first end 221 and a second end 222 . The first secondary winding 250 includes a third end 223 and a fourth end 224 . The first end 221 and the fourth end 224 have the same name.

[0019] The auxiliary circuit 33 includes a second transformer 23 , a first diode 25 , a second diode 26 , a first capacitor 28 and an inductor 32 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com