Metering device

A technology of a metering device and a metering device, which is applied in the directions of feeding device, injection device, injection device, etc., can solve the problem of inability to generate gaseous reactants without delay, and achieve improved atomization and distribution, reliable cost, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

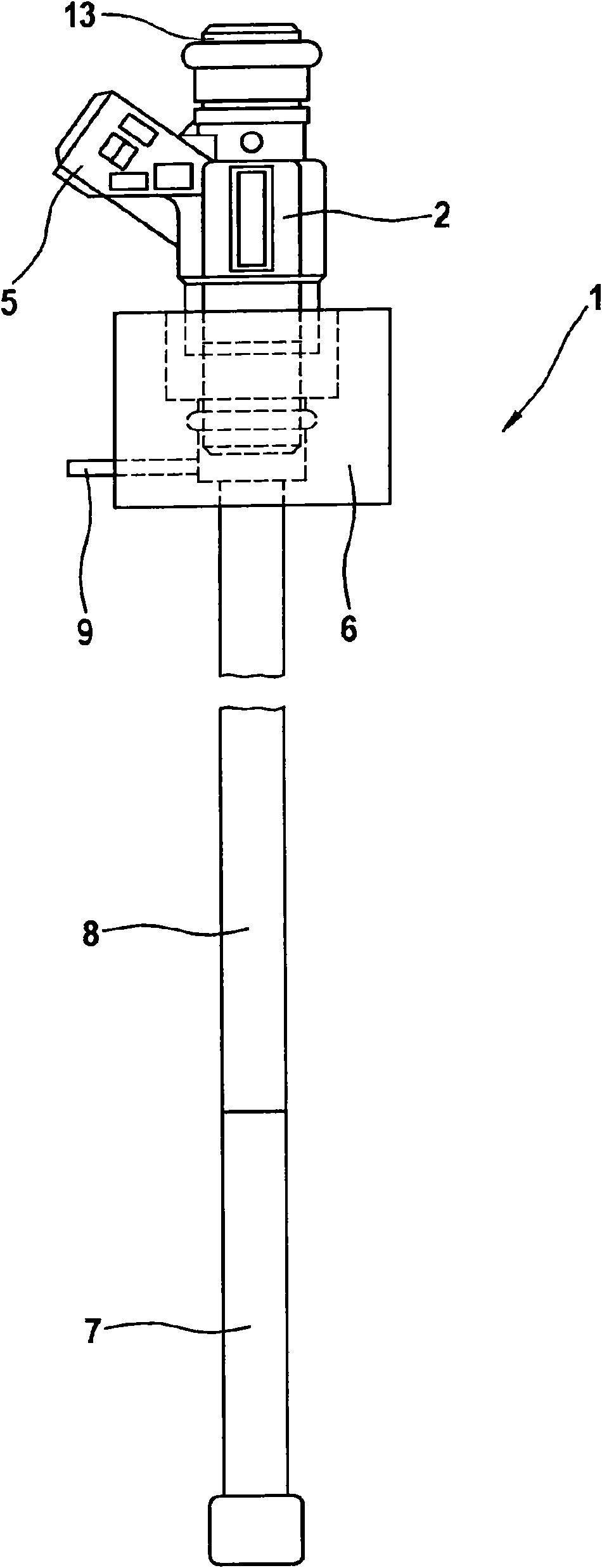

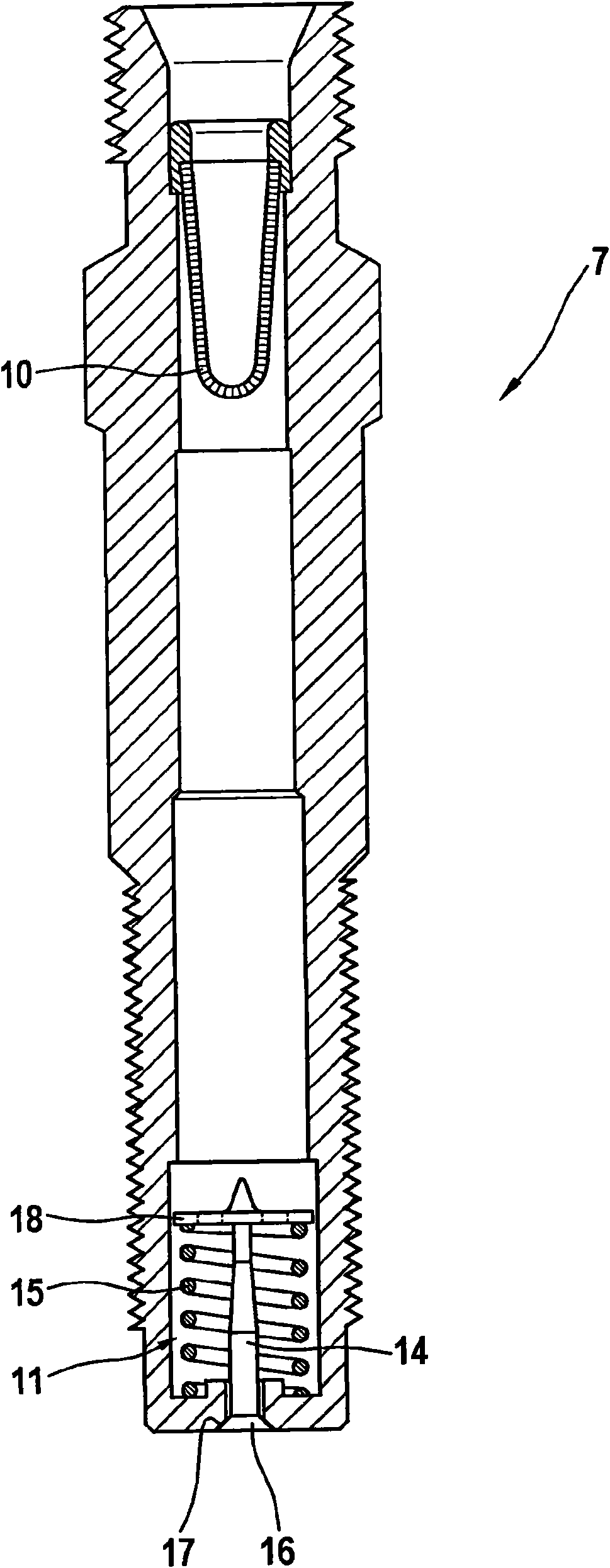

[0021] figure 1 The exemplary embodiment of a metering device 1 according to the invention shown in is implemented in the form of a metering device 1 for a low-pressure fuel injection valve. The metering device 1 is especially suitable for feeding and atomizing fuel or a fuel-gas mixture into a metering chamber (not shown) of a chemical converter (not shown) The reburning device is set to generate heat. Basically, however, such a metering device 1 is particularly suitable for metering fuel in hot surroundings. Known injection valves for the metering of media such as gasoline, diesel fuel, ethanol, methanol, aqueous urea solutions, etc. are designed for ambient temperatures of about 150° C., whereas the metering device 1 according to the invention, in addition to the already described In addition to other applications, it can also be used for exhaust gas aftertreatment or regeneration of particle filters, since in these applications the temperature reaches 700° C., which the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com