Insulating device and tensioning device for a high temperature fuel cell system component

A technology for high temperature fuel cells and system components, which is applied in the field of devices and can solve problems such as cracks in thermal insulation materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

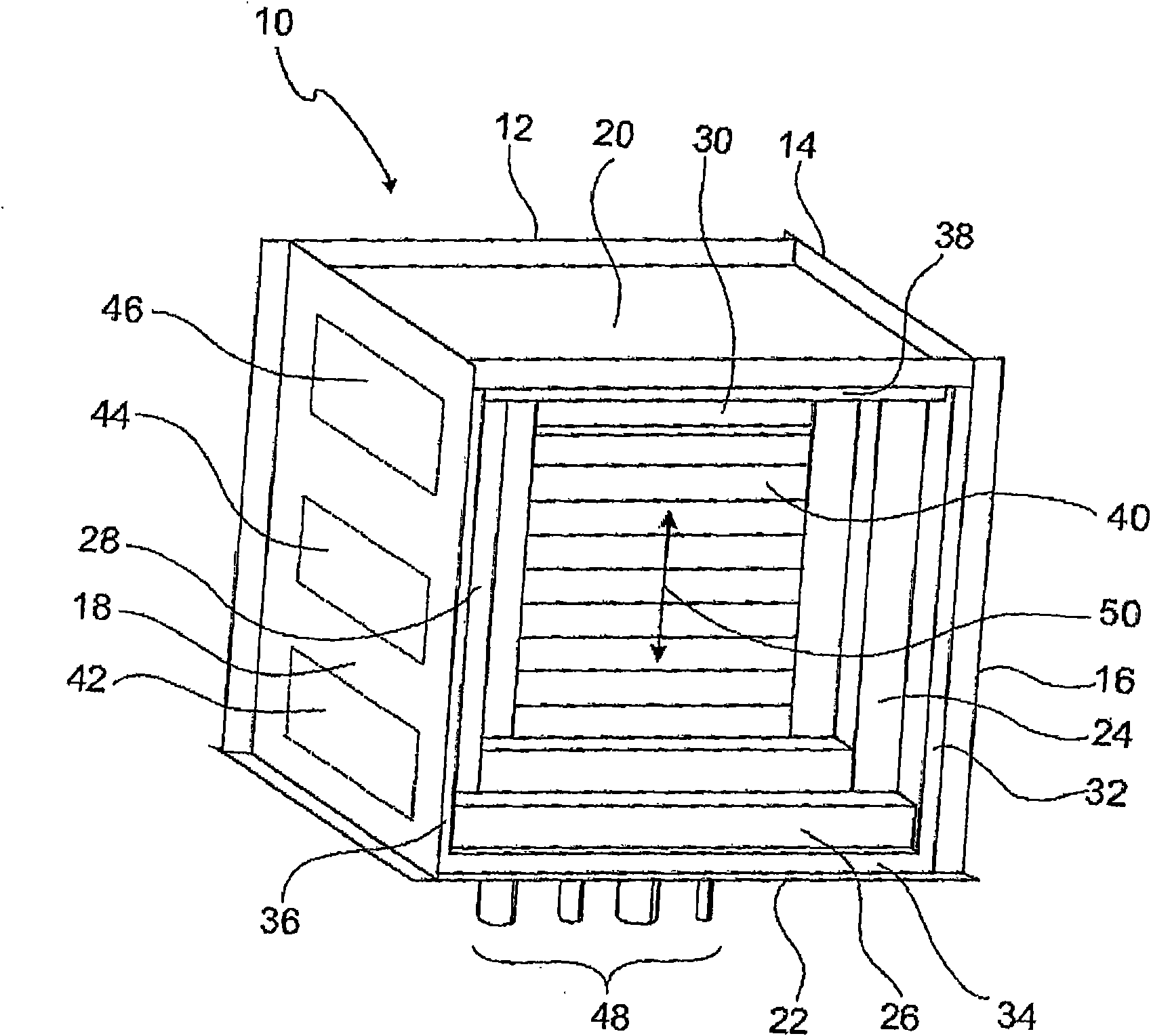

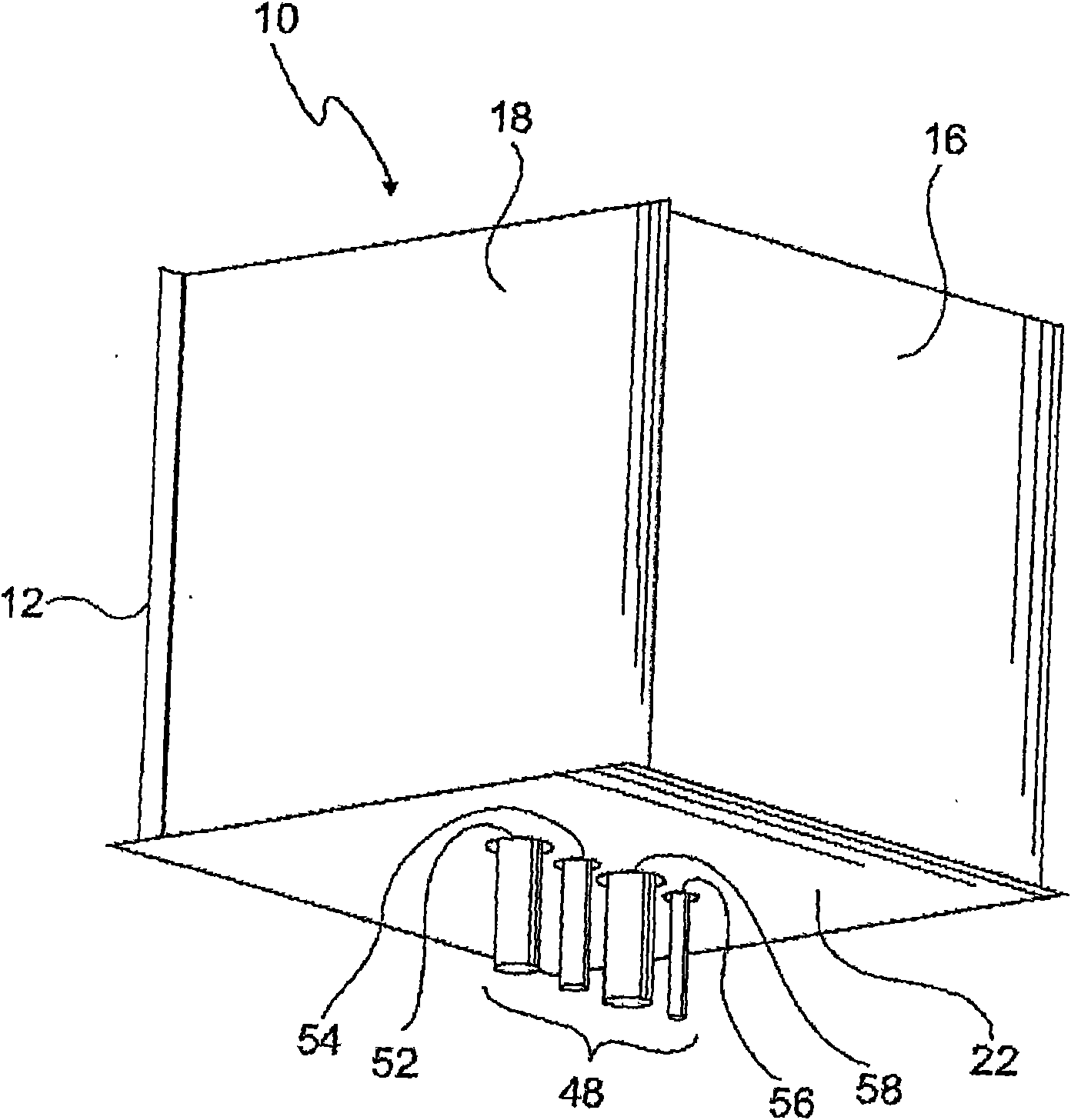

[0019] exist figure 1 The device 10 shown in FIG. 2 includes an insulated container in which at least one high temperature fuel cell system component is disposed. The vessel comprises a vessel shell formed from six mutually welded plates 12-22. The front panel 16 is shown partially cut away to allow a view of the internal structure of the device 10 . Inside the container housing 12 - 22 is arranged a high-temperature fuel cell stack 40 , the stack direction of which simultaneously also represents the preferred expansion direction 50 . The high temperature fuel cell stack 40 is connected to supply lines 48 which include, inter alia, an anode gas input and output and a cathode gas input and output. The supply lines 48 are led outwardly through the perforations 52 - 58 in the base plate 22 . The apparatus 10 may also house a reformer 42 and / or a combustor 44 and / or a controller 46, as shown by corresponding dashed boxes. The high temperature fuel cell stack 40 is surrounded b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com