Sleeve barrel structure of horizontal type numerical control boring-milling machine

A boring and milling machine and sleeve technology, which is applied in the field of horizontal CNC boring and milling machine sleeve structure, can solve problems such as high precision requirements, easy coaxiality, equipment processing accuracy and service life, and increase the moment of inertia , Improve machining accuracy and reduce vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

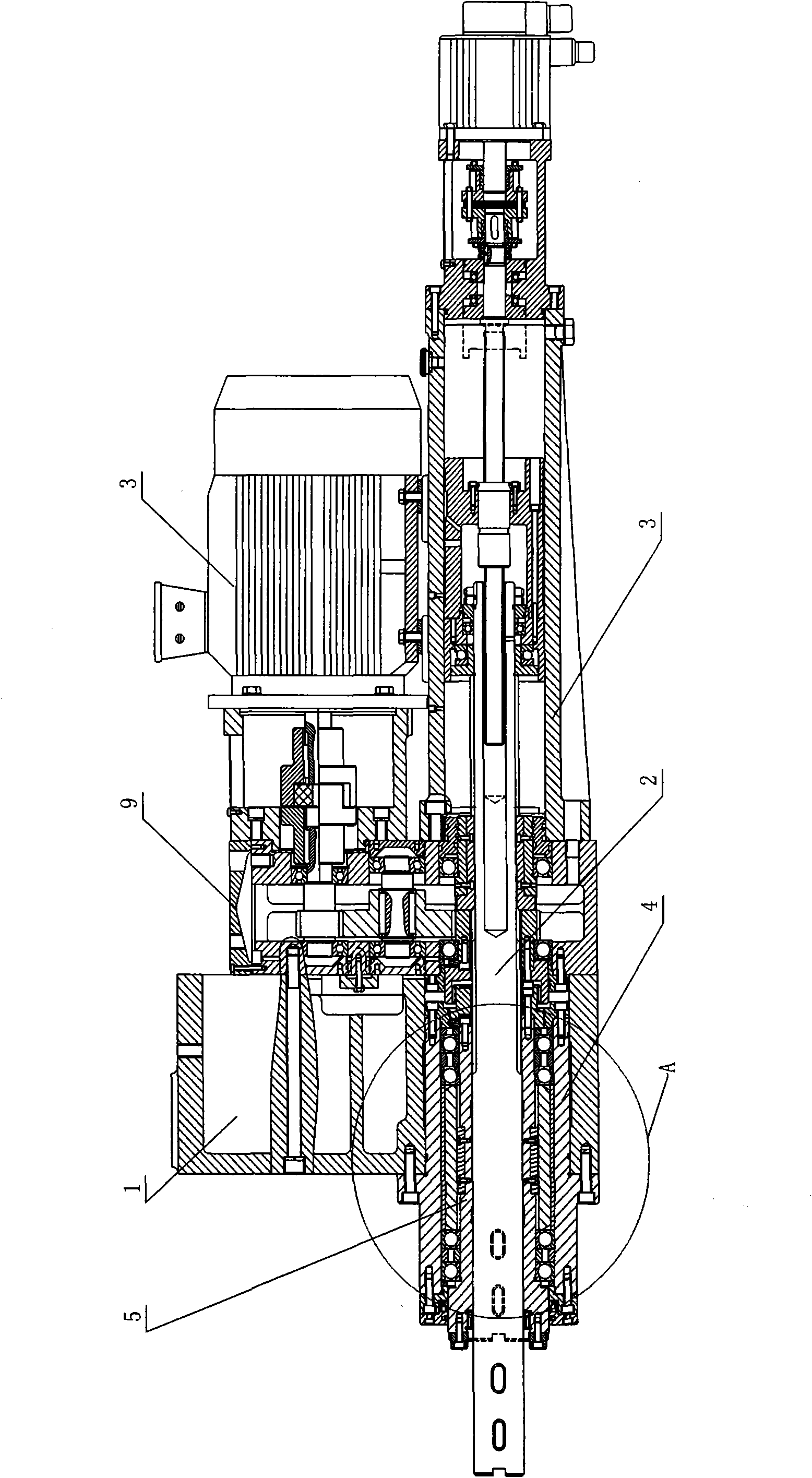

[0015] The horizontal numerical control boring and milling machine of the present invention includes a bed, a large column, a sliding block 1 , a fixed sleeve 4 and a gear box 9 installed on the sliding block 1 .

[0016] refer to figure 1 , is the structure diagram of the slider 1 and the boring bar 2 of the horizontal CNC boring and milling machine. The gearbox 9 is connected to the motor, and the gearbox 9 is connected to the tail barrel 3. The sleeve 5 is installed inside the fixed sleeve 4. The boring bar 2 is installed inside the tail barrel 5 and the tail barrel 3 , and the motor drives the boring bar 2 and the sleeve 5 to run at the same time by driving the reduction gear in the gear box 9 .

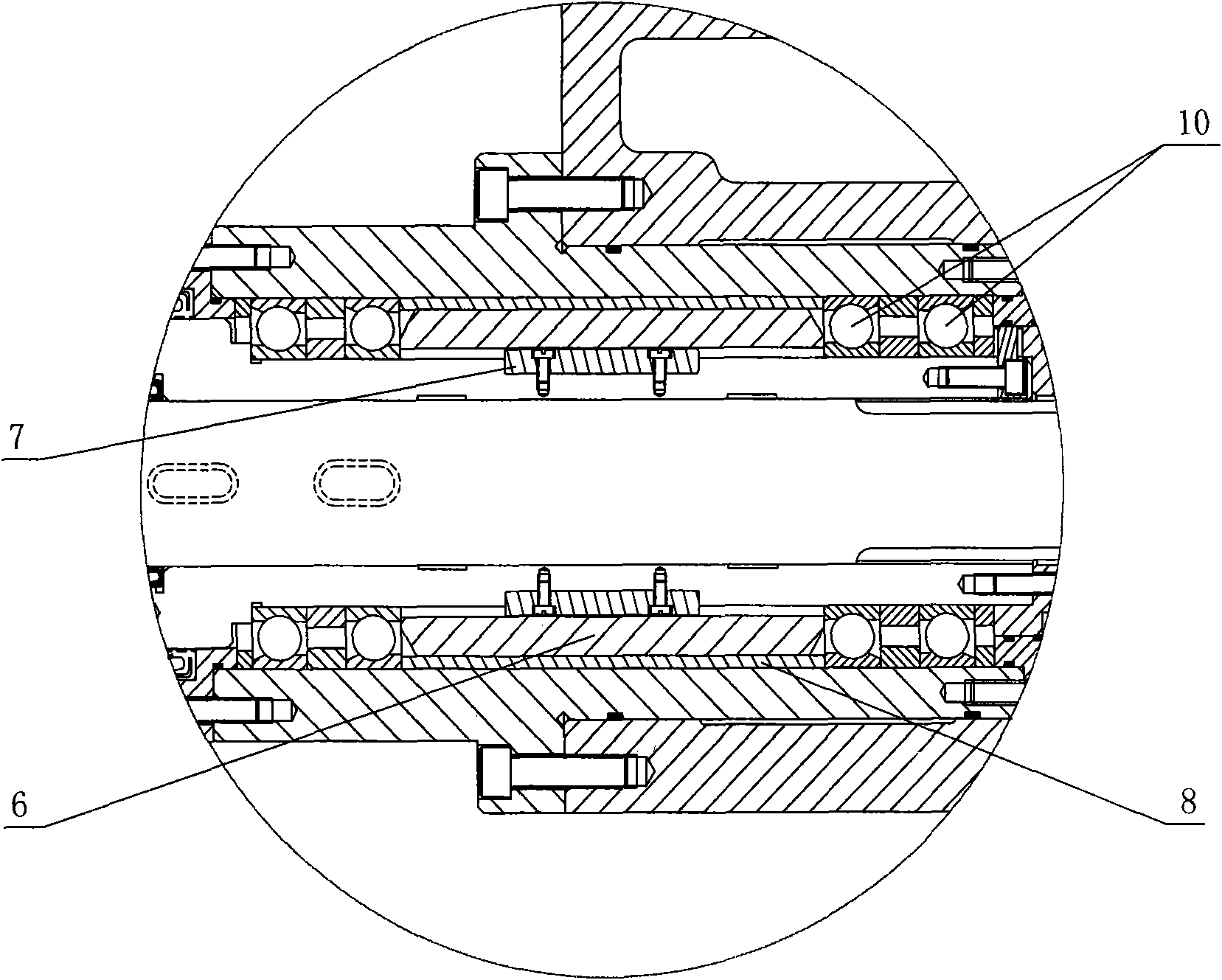

[0017] refer to figure 2 , the sleeve structure of the horizontal CNC boring and milling machine of the present invention, the sleeve 5 is installed inside the fixed sleeve 4, the inside of the sleeve 5 is the boring bar 2, and a balance sleeve is arranged between the sleeve 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com