Tooling device

A tooling and ejector device technology, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., to achieve the effect of automatic welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

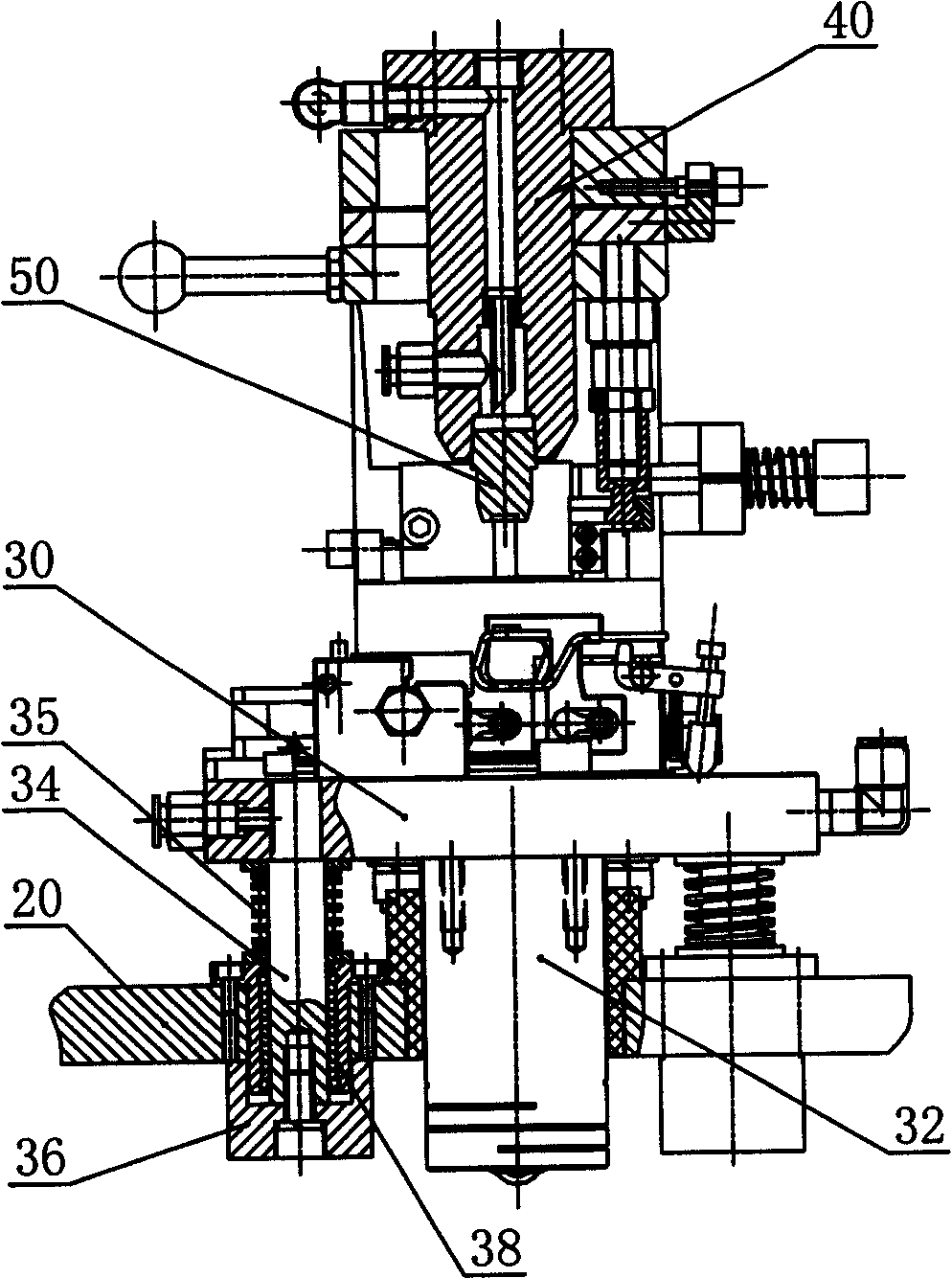

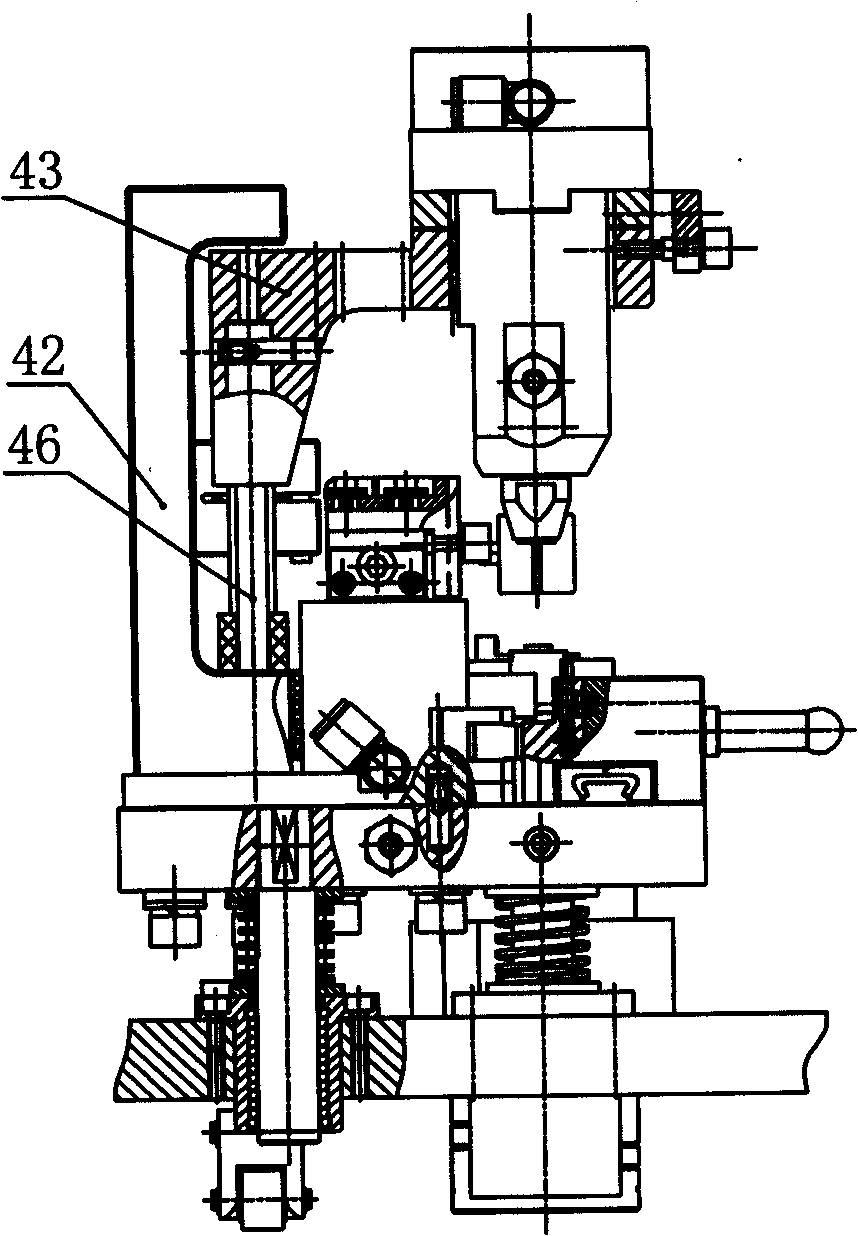

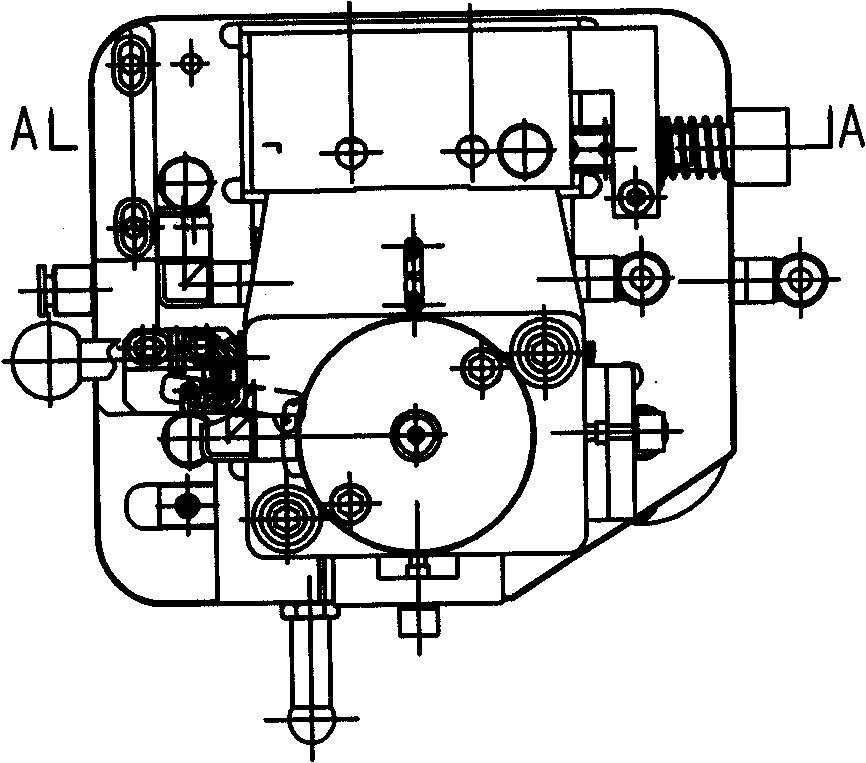

[0026] A tooling device includes a tooling base, a lower electrode assembly, and an upper electrode assembly.

[0027] Refer below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Further description of the tooling device:

[0028] The lower electrode assembly includes a compression spring 35 , a support plate 30 , and a lower transition electrode body 32 , and the upper electrode assembly includes a first guide shaft 46 , a mounting frame 43 and an electrode head 50 . The tooling base 20 is connected with the machine base of the welding machine, and is a basic component supporting the entire tooling device. Generally, the tooling base 20 is arranged horizontally.

[0029] In the lower electrode assembly, the support plate 30 is parallel to the tool base 20 , and a compression spring 35 is arranged between the tool base 20 and the support plate 30 . In order to support the support plate 30 and the entire lower electrode assembly in a balanced manner, the tooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com