Thrust generating apparatus

A technology for generating devices and thrust, applied in ship propulsion, propulsion components, transportation and packaging, etc., can solve the problems of complicated mechanism, increased hull resistance, inflow of other objects, etc., and achieve the effect of high-efficiency steering and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

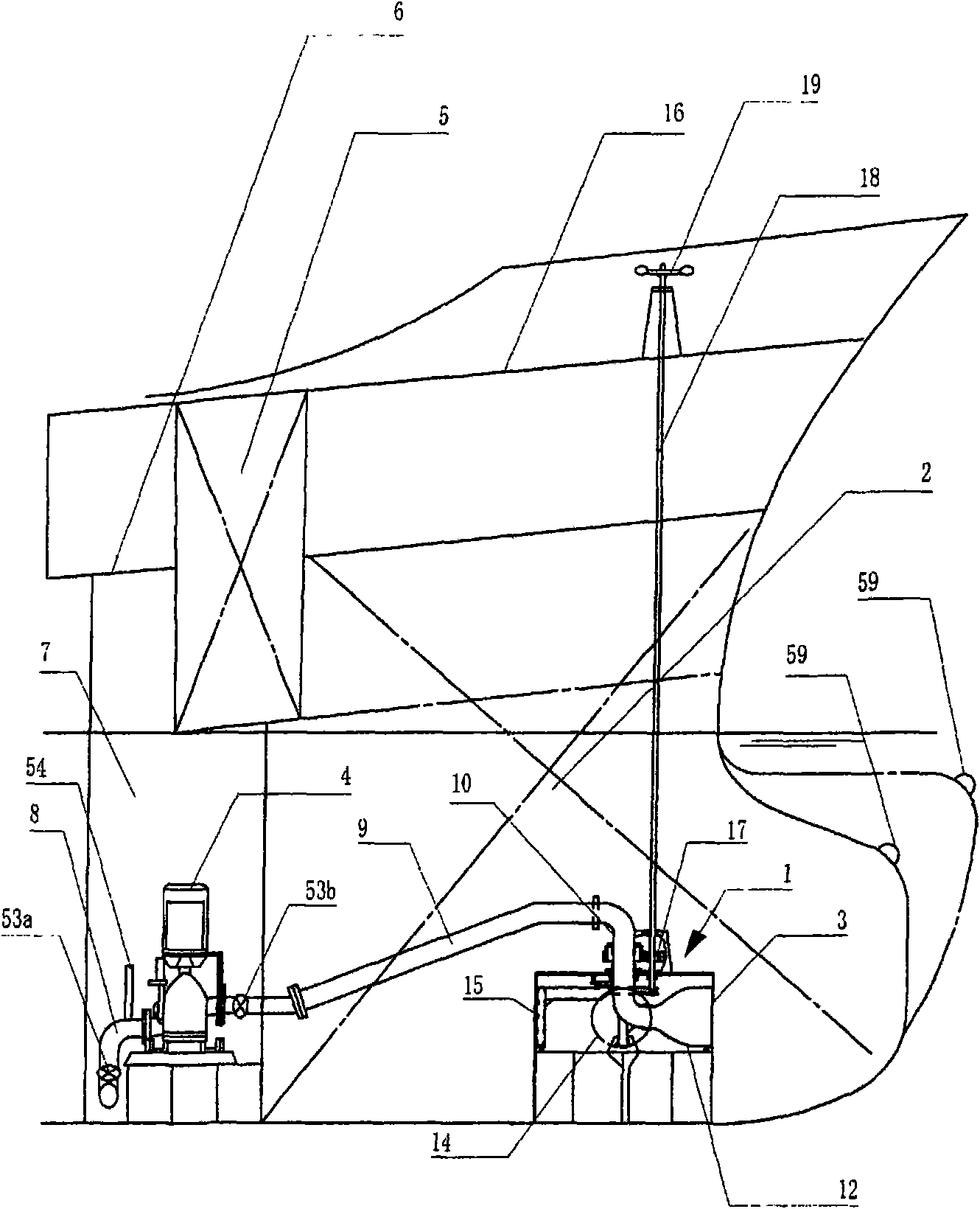

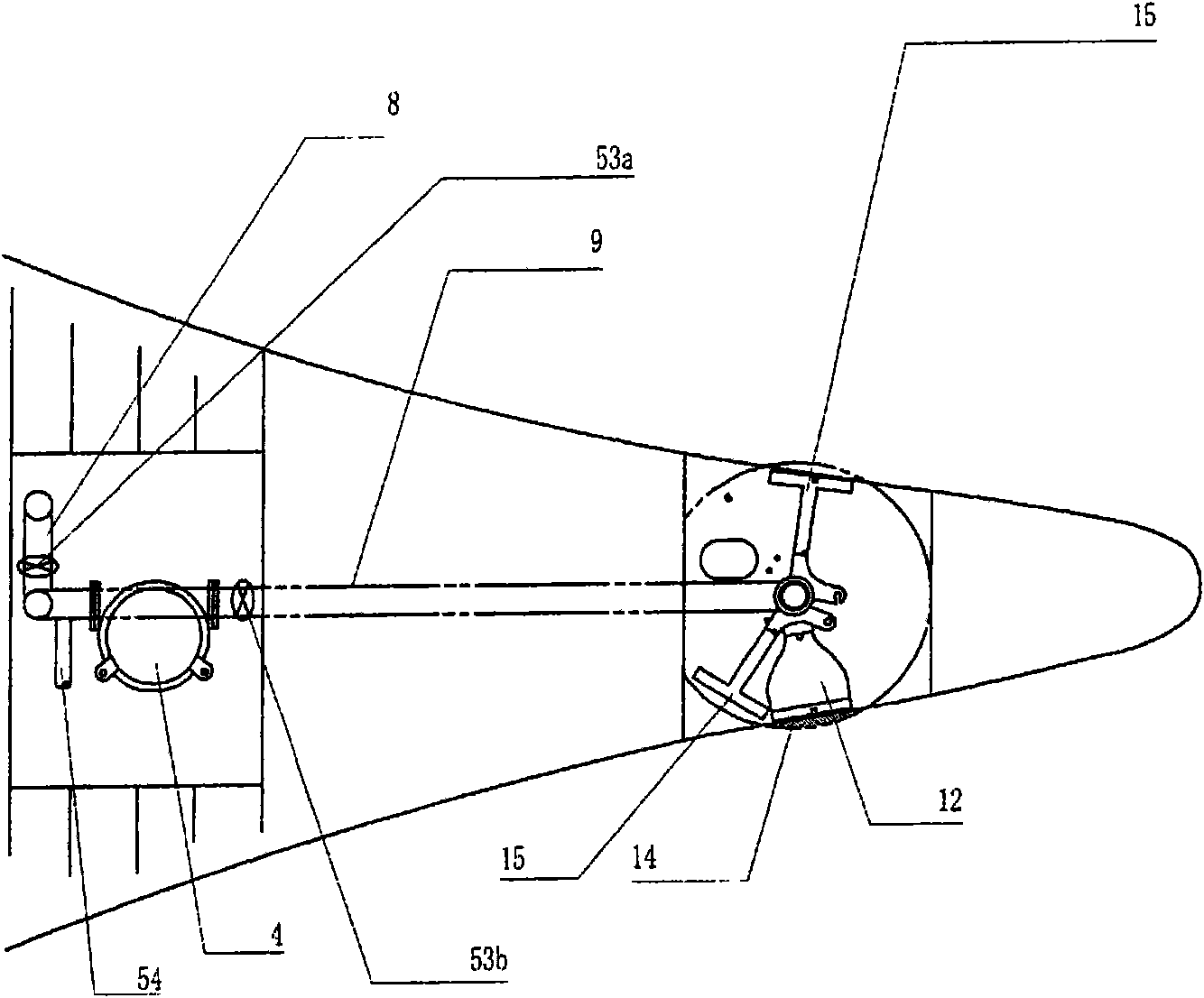

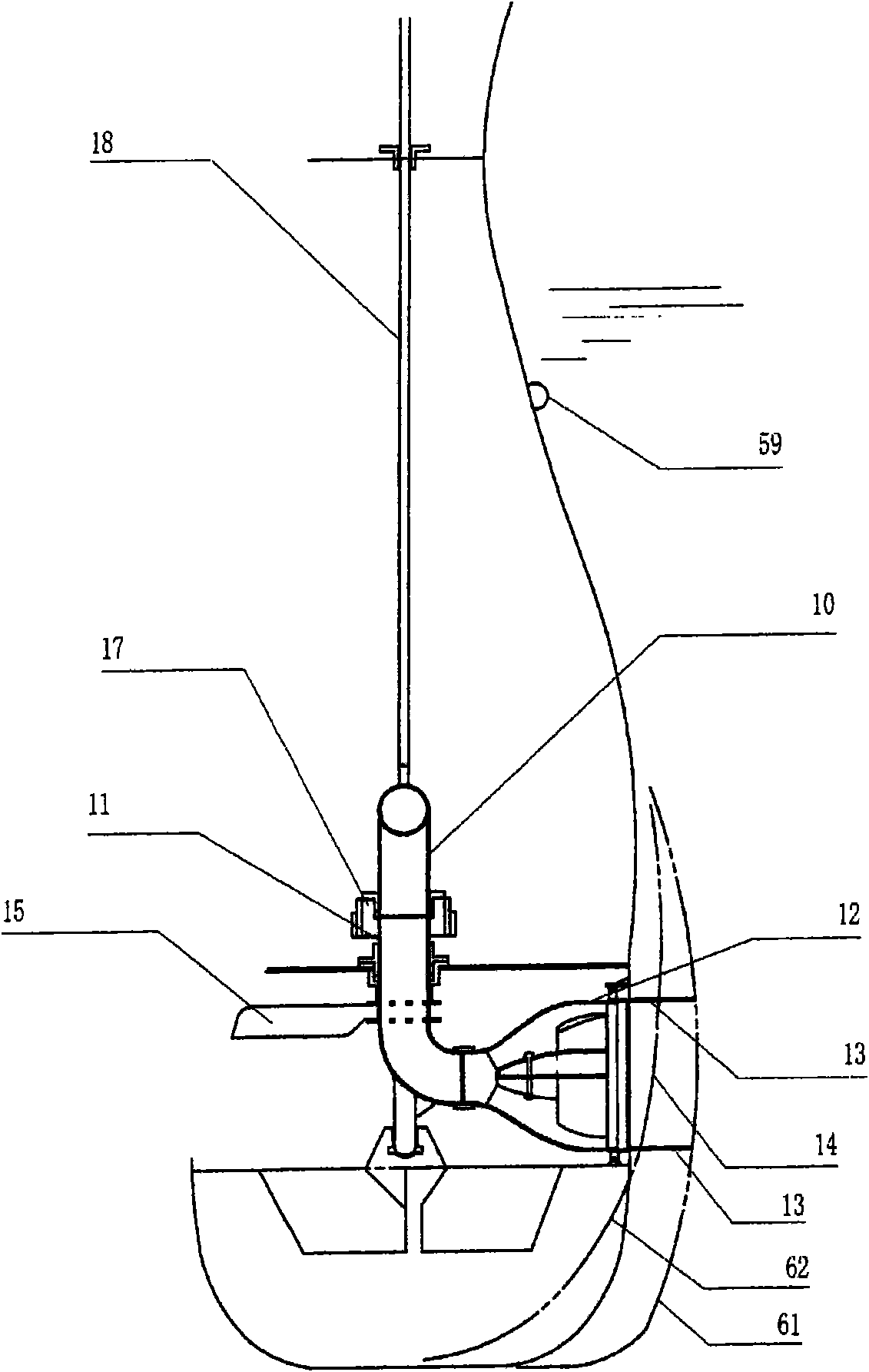

[0066] Next, the configuration of the present invention will be described in detail with reference to the following figures.

[0067] figure 1 It is a longitudinal sectional view of the bow of the device installed with the present invention; figure 2 is a plan view of the floor surface on which the device is installed; image 3 is a cross-sectional view of the location of the device at the end of the bow; Figure 4 is a longitudinal sectional view of the nozzle of the thrust generating device of the device; Figure 5 is a front view showing the structure of the nozzle; Figure 6 , Figure 7 and Figure 8 It is a plan view showing the operating positions of the nozzles and revolving doors in the thrust generator chamber; Figure 9 and Figure 10 is a detailed drawing of the revolving center of the revolving door; Figure 11 yes Figure 6 A-A direction view; Figure 12 yes Figure 11 C-C direction view; Figure 13 yes Figure 11 D-D direction view; Figure 14 yes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com