Natural ventilation method for relieving sill-lifting cavitation of high-lift ship lock sudden-enlargement gallery

A high water head and ship lock technology, applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of increasing project investment and construction difficulty, increasing the length and volume of sudden expansion corridors, and increasing project maintenance costs, etc., to achieve improvement The effect of engineering safety, simple structure, and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

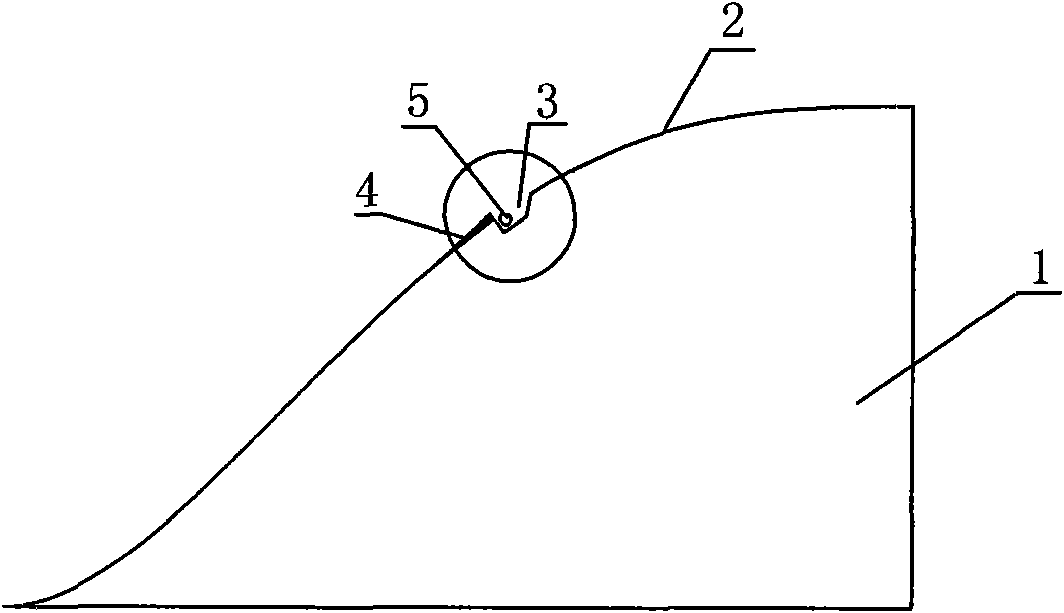

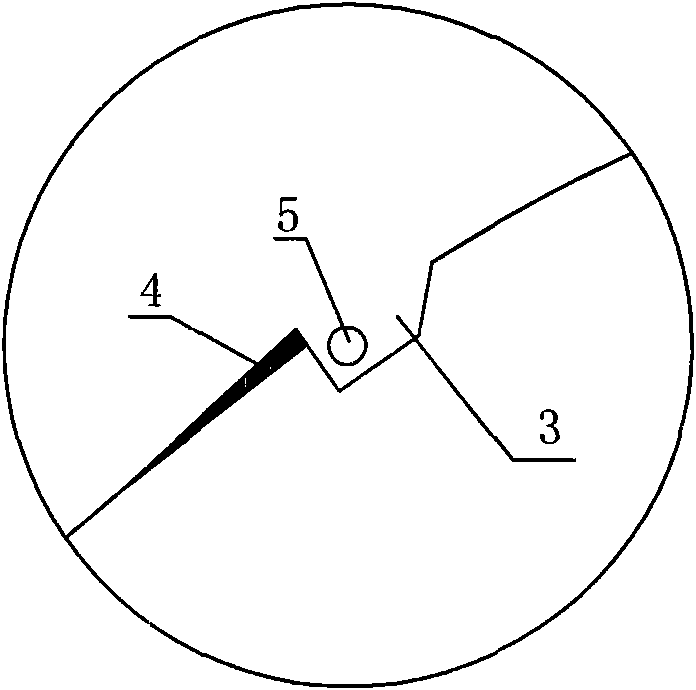

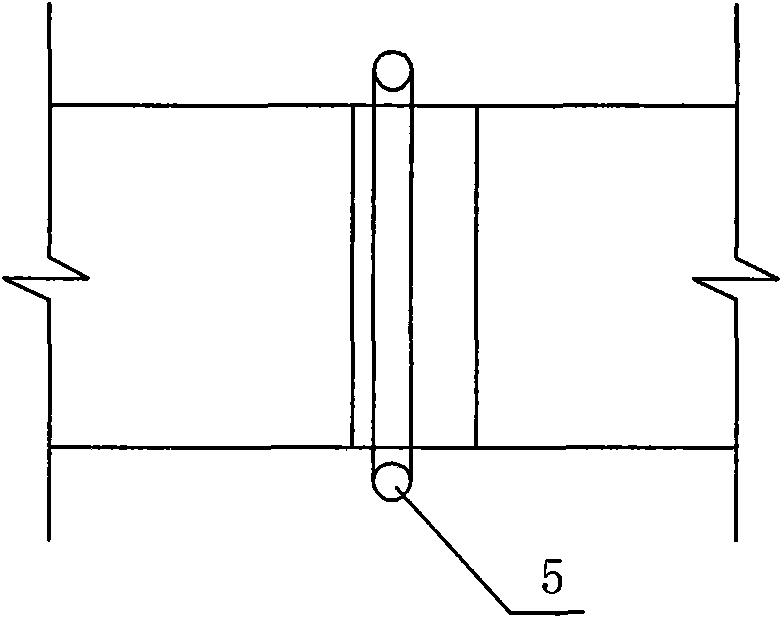

[0018] The present invention is a natural ventilation method for reducing the cavitation of the rising sill in the sudden expansion corridor of the high water head ship lock. figure 1 , figure 2 and image 3 As shown, the riser 1 adopts a quintic curve type riser, and the aeration groove 3 and its wedge-shaped deflector 4 are arranged at the position where the water flow separates on the riser surface 2 to form a stable low-pressure area. The position adds vent pipe 5, to realize natural ventilation. A wedge-shaped sill 4 is arranged in front of the aeration tank 3, so that the water flow will not be separated before the sill is lifted, and a high flow rate is maintained, thereby forming a stable ventilation cavity after the sill is lifted. An air pipe 5 is respectively arranged on both sides of the aeration tank 3 to the top of the gate.

[0019] Figure 4 , Figure 5 and Image 6 It is the measured cavitation noise. This data is obtained under the decompression model ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com