Scroll compressor

A scroll compressor, scroll technology, applied in the field of scroll compressors, to achieve the effect of eliminating bad phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

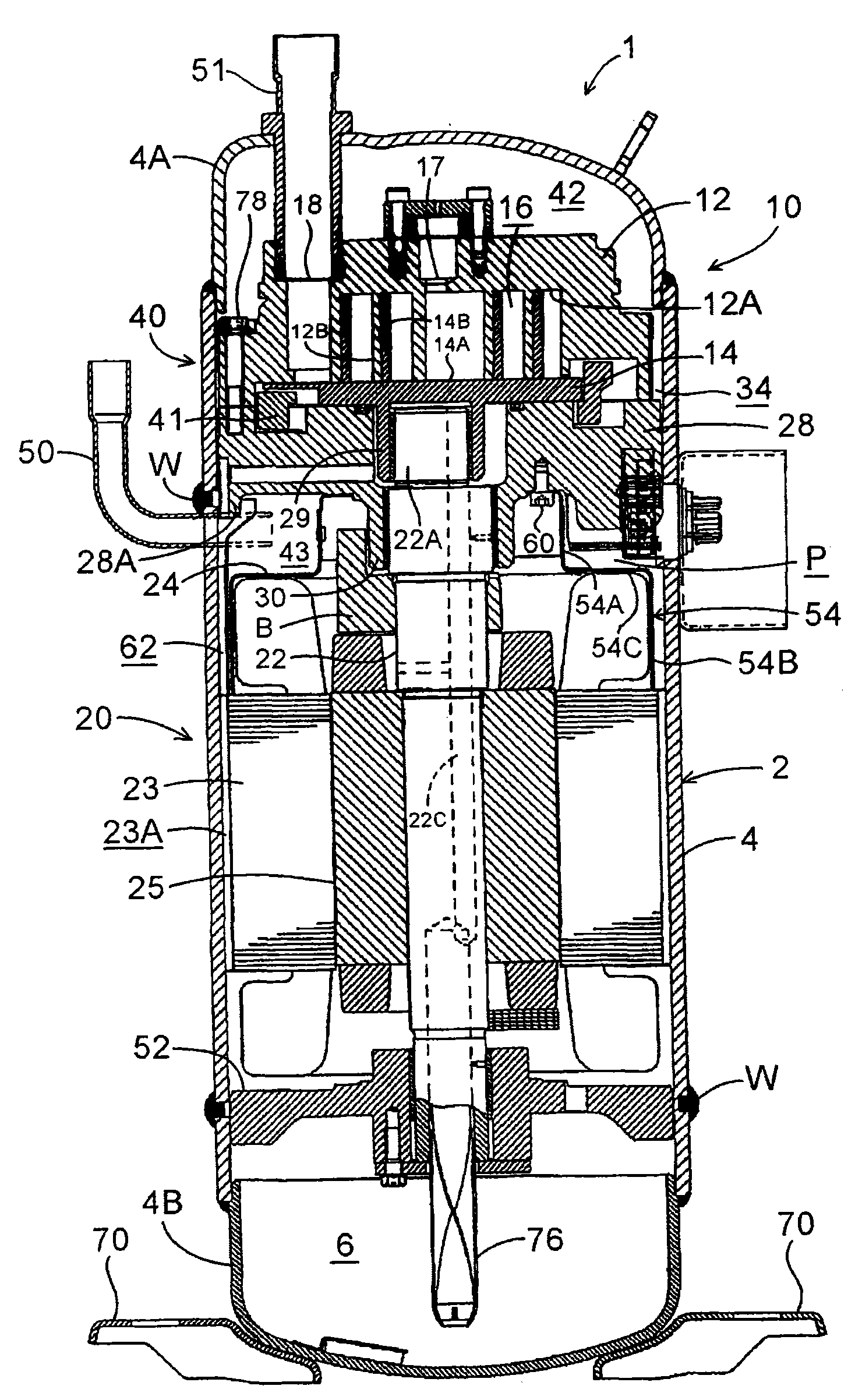

[0042] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is a longitudinal sectional side view of an internal high-pressure type scroll compressor 1 having a scroll compression unit 10 showing an embodiment of the present invention.

[0043] The scroll compressor 1 in this embodiment belongs to the internal high pressure type, such as figure 1 As shown, its structure includes: an elongated cylindrical airtight container 2 made of steel plates, an electric assembly 20 (electric motor) arranged and accommodated in the inner space of the airtight container 2 , and an upper side of the electric assembly 20 The scroll compression assembly 10 is driven by the rotating shaft 22 of the electric assembly 20 . The structure of the airtight container 2 includes: a container body 4 for accommodating the electric assembly 20 and the scroll compression assembly 10, a bowl-shaped end cap 4A installed for closing the upp...

Embodiment 2

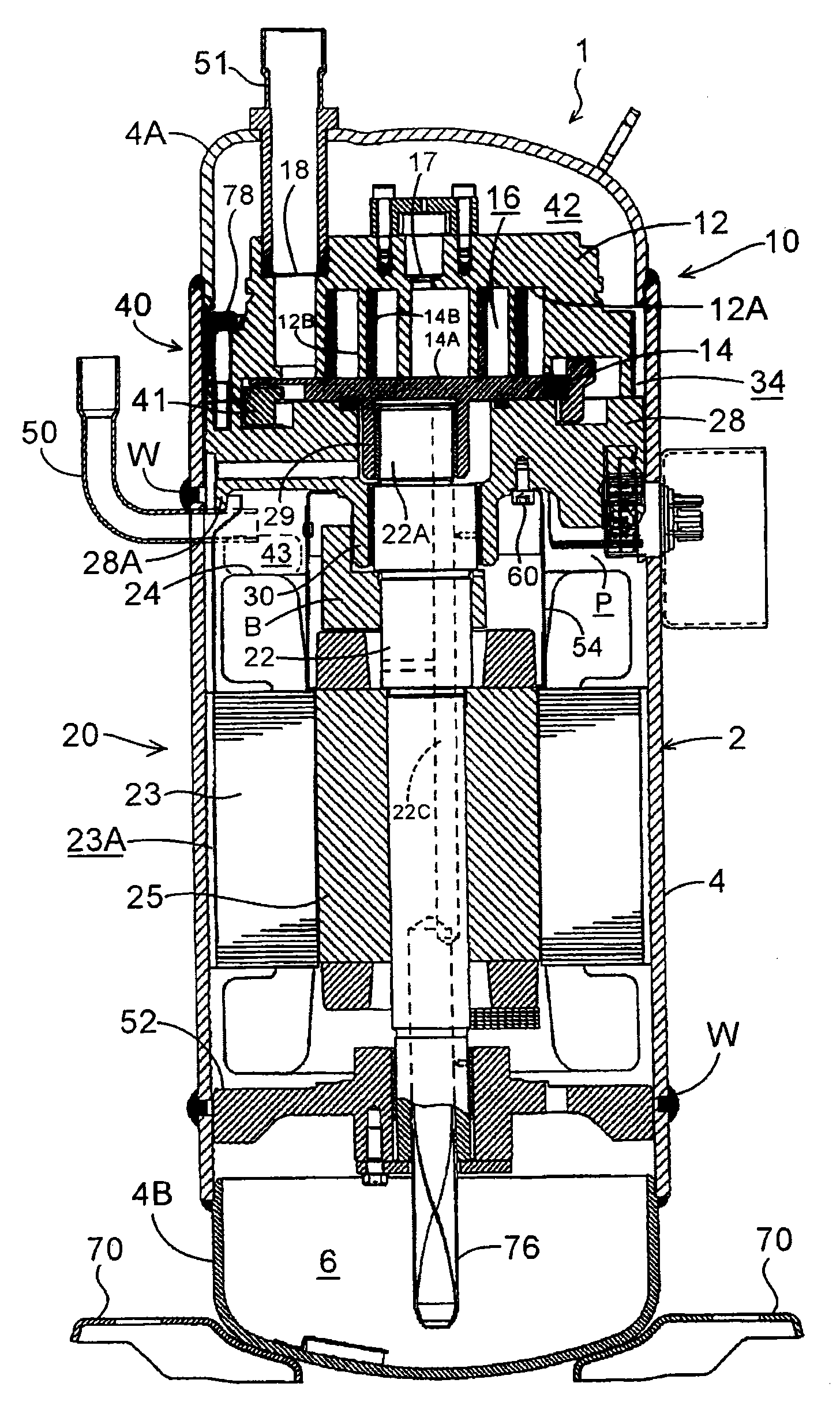

[0069] exist figure 2 A scroll compressor 1 according to another embodiment of the present invention is shown in FIG. This scroll compressor 1 has substantially the same structure as the above-mentioned embodiment. Next, the different parts will be described. In addition, the same code|symbol is attached|subjected to the same part as the above-mentioned embodiment, and the description is abbreviate|omitted. That is, if figure 2 As shown, the scroll compressor 1 is formed by changing the shape of the shielding plate 54 described in the foregoing embodiments.

[0070] The shielding plate 54 is provided outside the bearing portion 30 at a predetermined interval, and the lower edge of the shielding plate 54 extends to the stator 23 located slightly below the upper surface of the coil end 24 on the rotor 25 side. near the upper end of the stator coil and abut against the stator core. That is, the shielding plate 54 is arranged inside the coil end 24 of the stator 23, between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com