Device and method for positioning and blocking steady rests for rolling milly cylinders in grinding machines and grinding machines employing the same

A technology of a locking device and a center frame, applied in the field of grinding machines, can solve the problems of high cost, long period of time, affecting the production cost of grinding machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

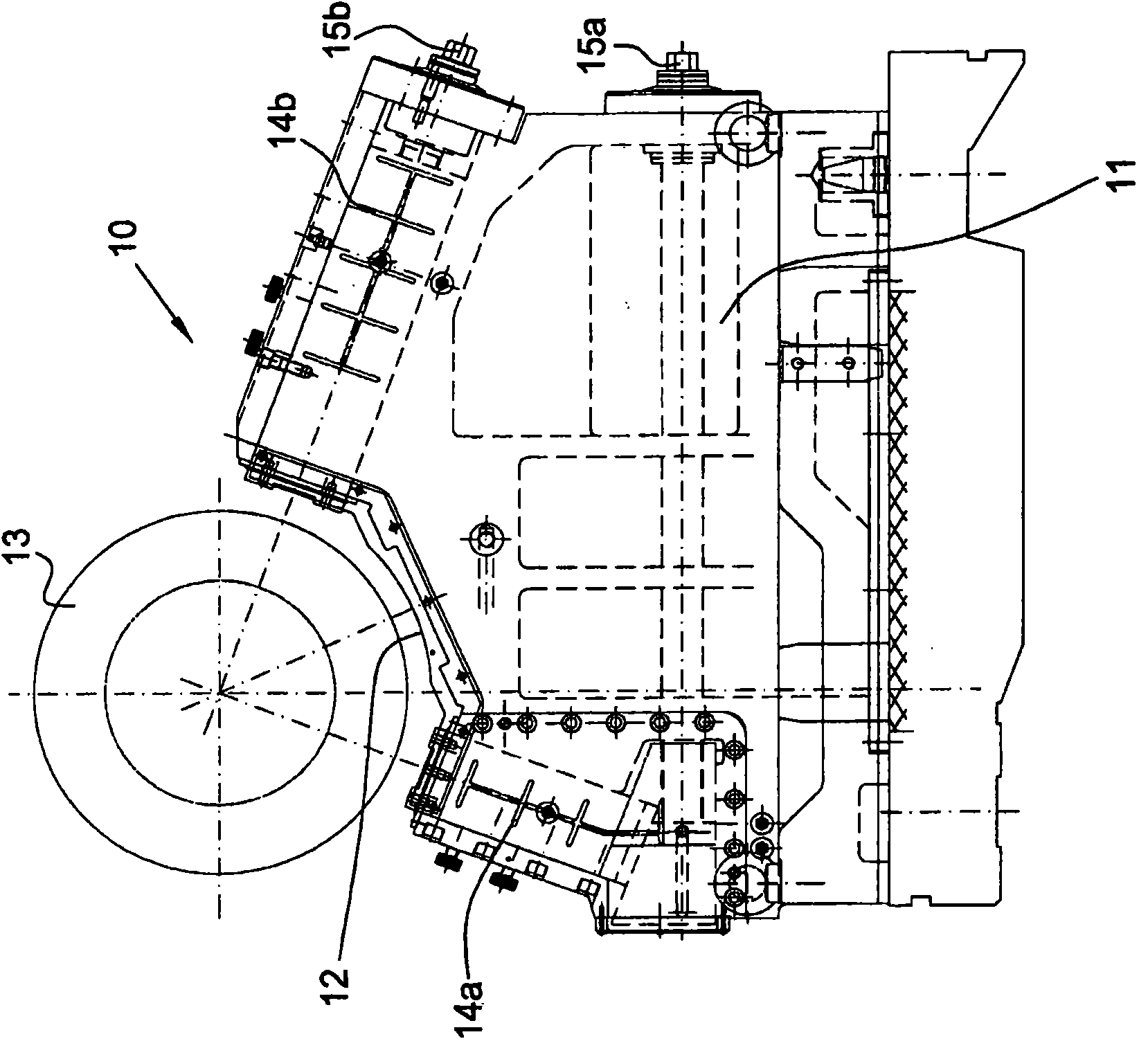

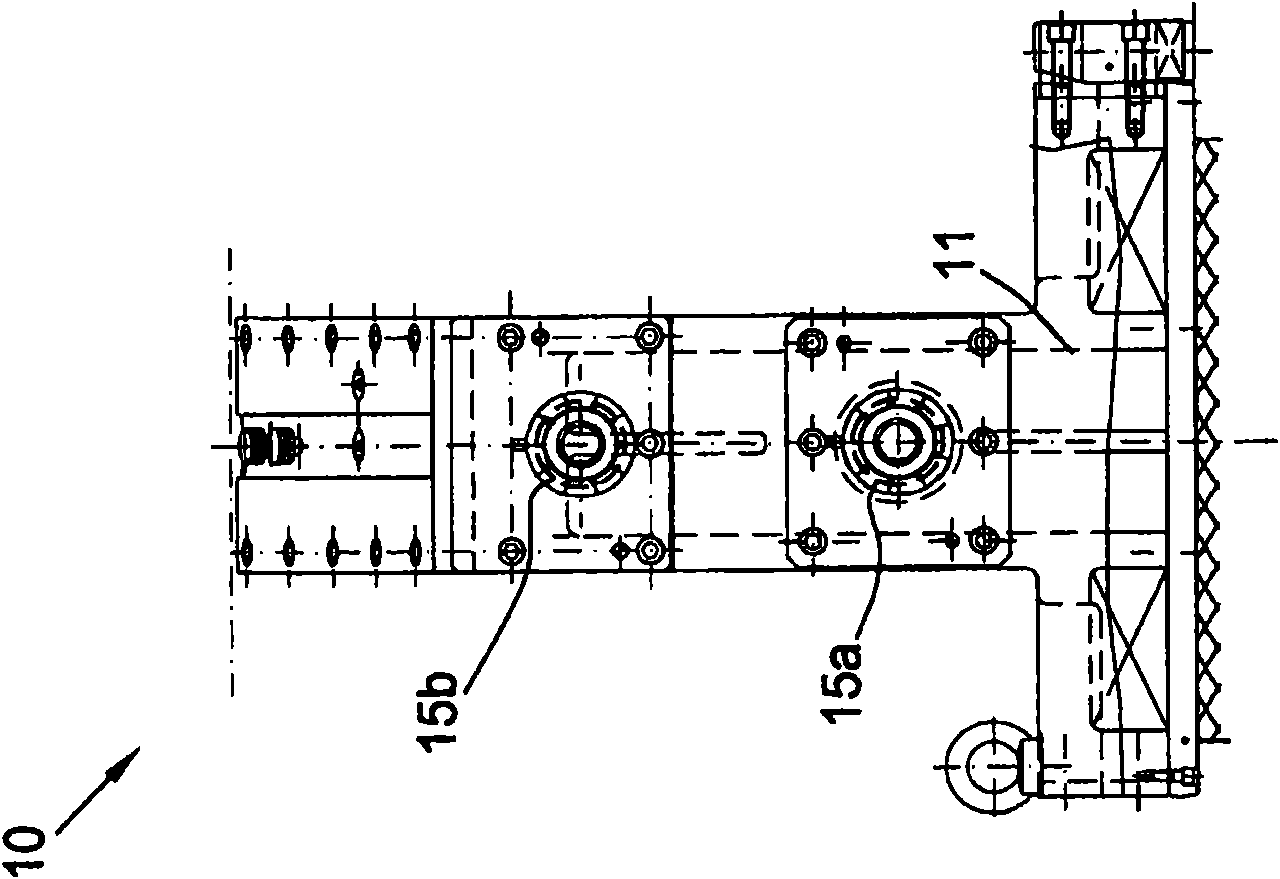

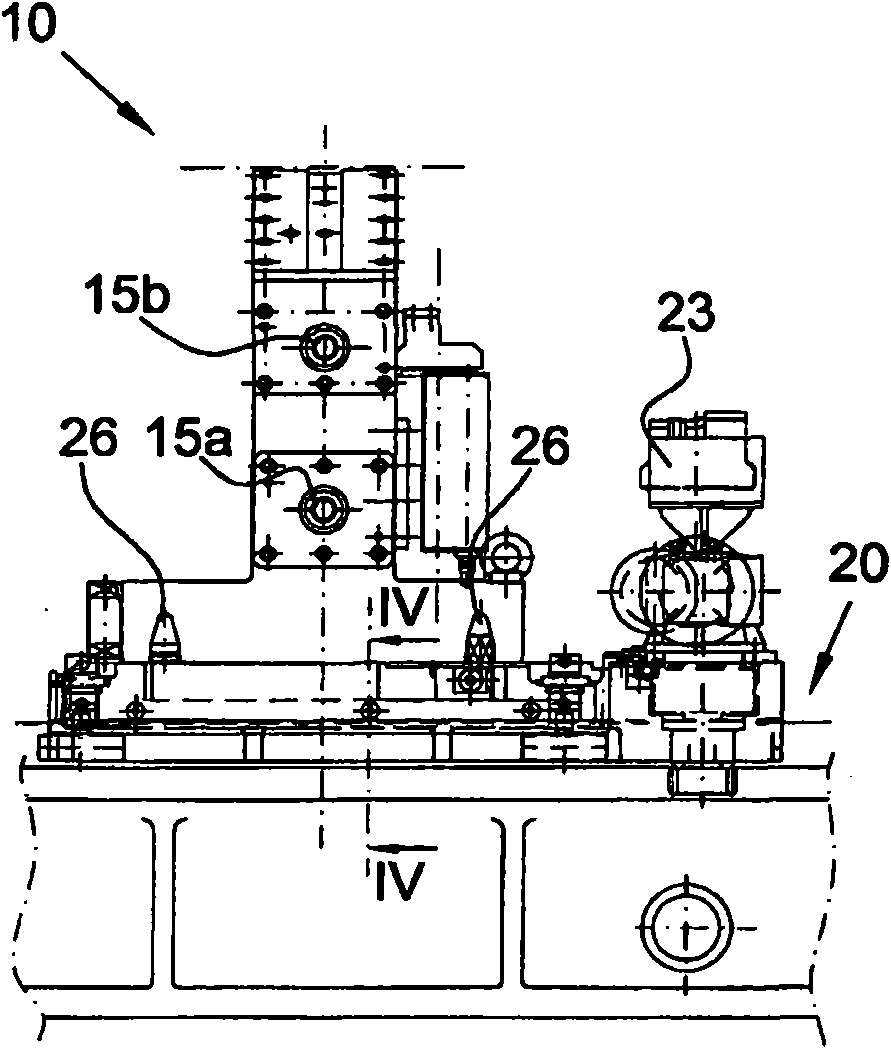

[0023] With reference to the accompanying drawings, a steady frame employing positioning and locking means 20 (subject of the invention) is indicated in its entirety with 10 and, in the example shown according to the invention, it comprises a support body 11 with a On the arrangement surface 12 of the rolling cylinder 13.

[0024] Furthermore, at least two radially adjustable engagement means 14a, 14b are provided for engaging the cylinder 13 to be ground, the cylinder 13 protruding from the arrangement surface 12 guided by the corresponding adjustment means 15a, 15b.

[0025] The center frame 10 is housed in a detachable manner on a positioning and locking device 20 comprising a flat support 21 with translation means 23 motorized for moving the center frame 10 into position. Furthermore, this positioning and locking device 20 comprises a centering pin 26 for precisely positioning the main body 11 of the center frame 10 on the positioning and locking device 20 , moreover, this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com