Pneumatic tire

A technology of pneumatic tires and tires, which is applied to the reinforcement layer, tire parts, tire edges and other directions of pneumatic tires, can solve problems such as failure and breakage, and achieve the effect of inhibiting the deterioration of riding comfort and improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

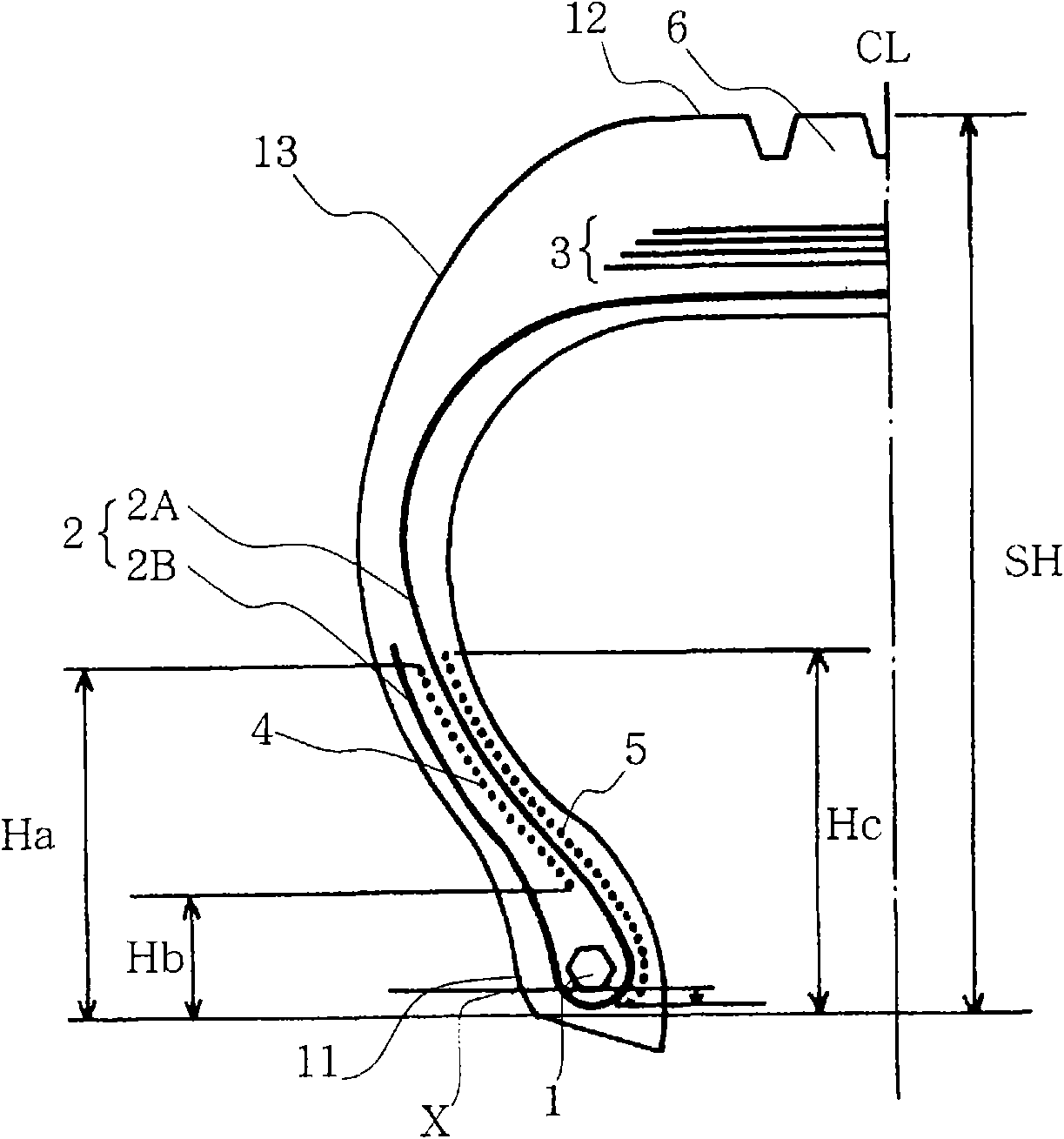

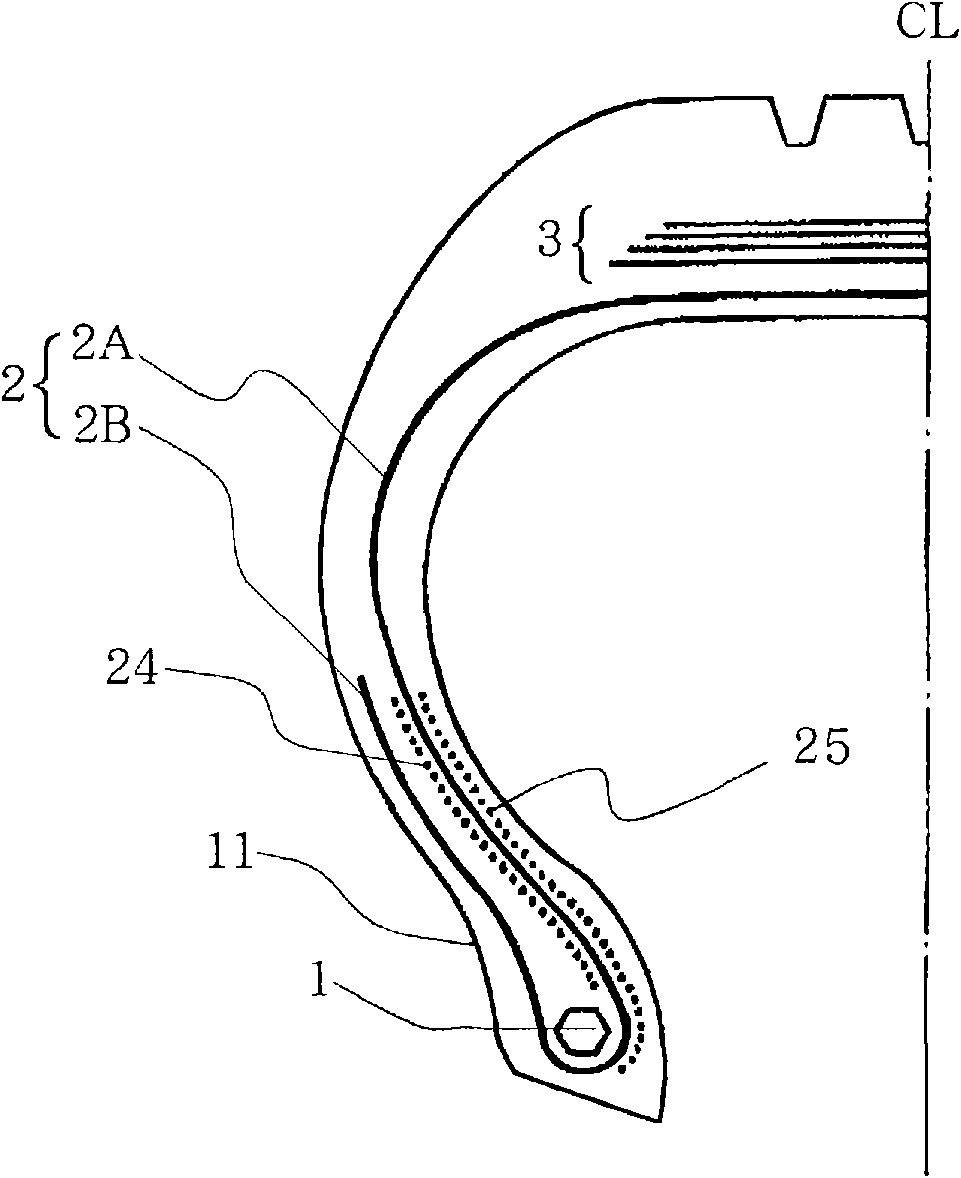

[0039] Such as image 3 The pneumatic tire shown includes a steel wire radial carcass layer 2 and four steel belt belt layers 3 arranged on the outer side of the steel wire radial carcass layer 2 in the tire radial direction, and the above one steel wire radial carcass layer 2 is folded back from the inside to the outside around the bead cores 1 embedded in the pair of bead parts 11 and locked, and is composed of main parts 2A and 2B, and the main part 2A extends in a ring shape between the bead cores 1 The above-mentioned folded portion 2B is provided continuously with the main body portion, and is folded around the bead core 1, and the outer sidewall reinforcement is respectively arranged on the outer side and the inner side of the main body portion 2A of the carcass layer in accordance with the conditions described in Table 1 below. layer 24 and the inner sidewall reinforcing layer 25 to manufacture the pneumatic tire of Example 1.

Embodiment 2

[0041] Such as Figure 4 As shown, the pneumatic tire of Example 2 was produced in the same manner as in Example 1 except that the arrangement positions of the outer side reinforcing layer 34 and the inner side reinforcing layer 35 were changed under the conditions shown in Table 1 below. In addition, the inner sidewall reinforcing layer 35 in this case is separately arranged.

Embodiment 3

[0043] The arrangement conditions of the inner sidewall reinforcing layer 25 were the same as those of Example 1 except that Table 1 below was changed, and a pneumatic tire of Example 3 was manufactured.

[0044] Conventional Example 1

[0045] A pneumatic tire (not shown) of Conventional Example 1 was produced in the same manner as in Example 1 except that the outer side reinforcing layer and the inner side reinforcing layer were not provided.

[0046] Conventional example 2

[0047] Such as Figure 5 As shown, the pneumatic tire of Conventional Example 2 was produced in the same manner as in Example 1, except that only the outer side reinforcing layer 44 was provided and the inner side reinforcing layer was not provided. In addition, reference numeral 45 in the figure denotes a bead portion reinforcing layer.

[0048] Table 1

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com