Aircraft cabin window assembly method

A technology for aircraft and portholes, applied in the field of assembling portholes, can solve problems such as increased instrument maintenance costs, mechanical stability limitations, and increased bracket maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

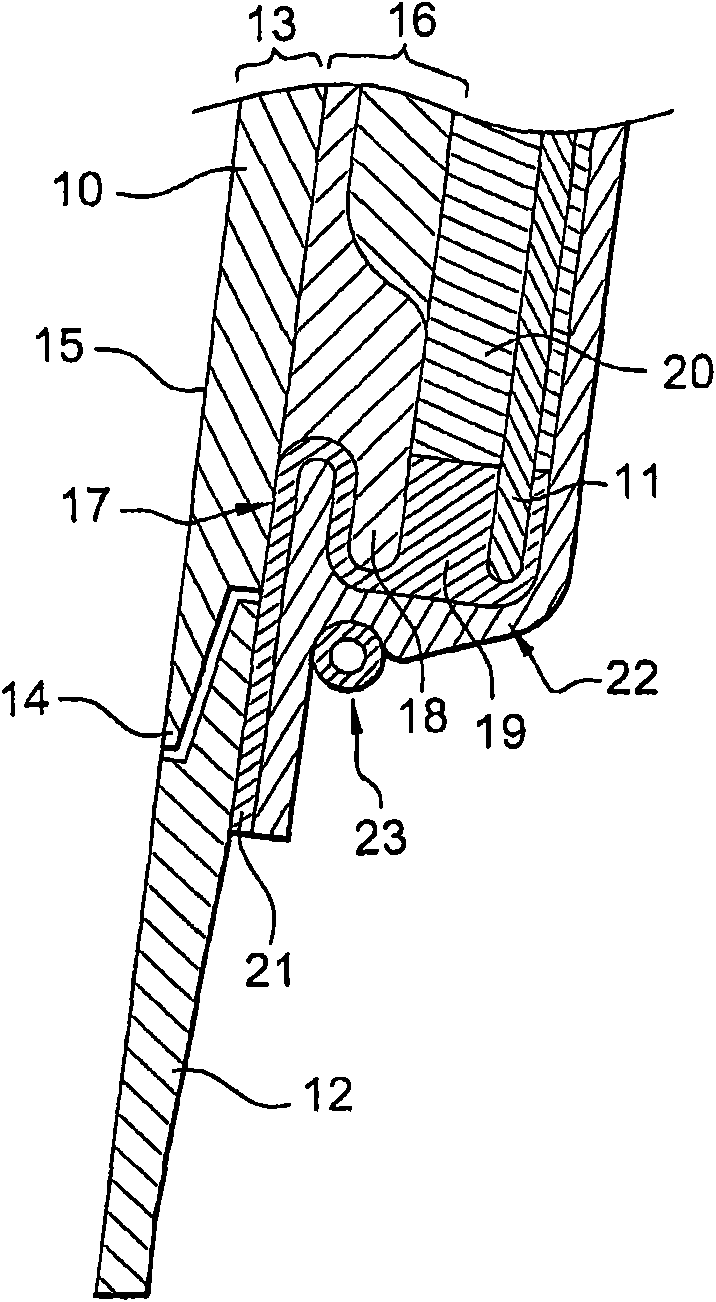

[0049] [49] image 3 A partial sectional view is shown of a porthole mounted on an opening formed in a side wall of an aircraft fuselage according to a particular embodiment of the invention.

[0050] [50] The porthole comprises an outer transparent element 10 and an inner transparent element 11 . The outer transparent element 10 is mounted on an opening formed in a side wall 12 of the aircraft fuselage. The fuselage can be metal, or made of a synthetic material such as carbon fibre.

[0051] [51] The outer transparent element 10 is a one-piece piece. The outer transparent element comprises a first portion 13 having a diameter greater than the diameter of the opening. The first portion 13 comprises a partially chamfered edge 14 . The rim 14 thus has two substantially flat surfaces connected to each other by a bevel, so that it can be seen that the diameter of the first portion is reduced relative to its outermost surface 15 . As for its outermost surface 15, its shape ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com