Starter system with integral clutch pinion for start-stop engine cranking

A starter and pinion technology, applied in the field of devices for starting internal combustion engines, can solve the problems of reducing the service life of ring gears and starter motors, damage of ring gears and starter motors, and long-term cost of repairing ring gears, so as to improve economic efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

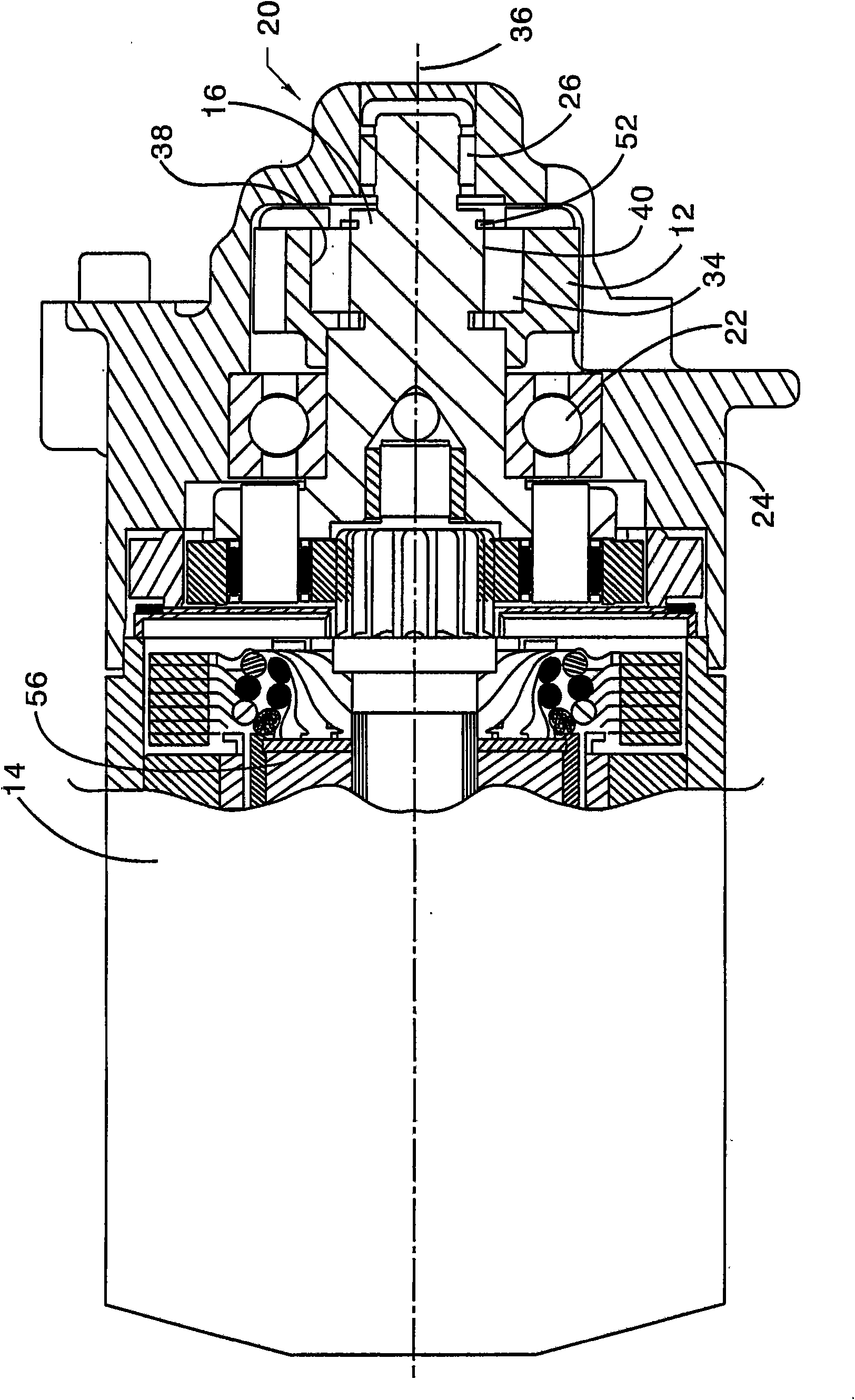

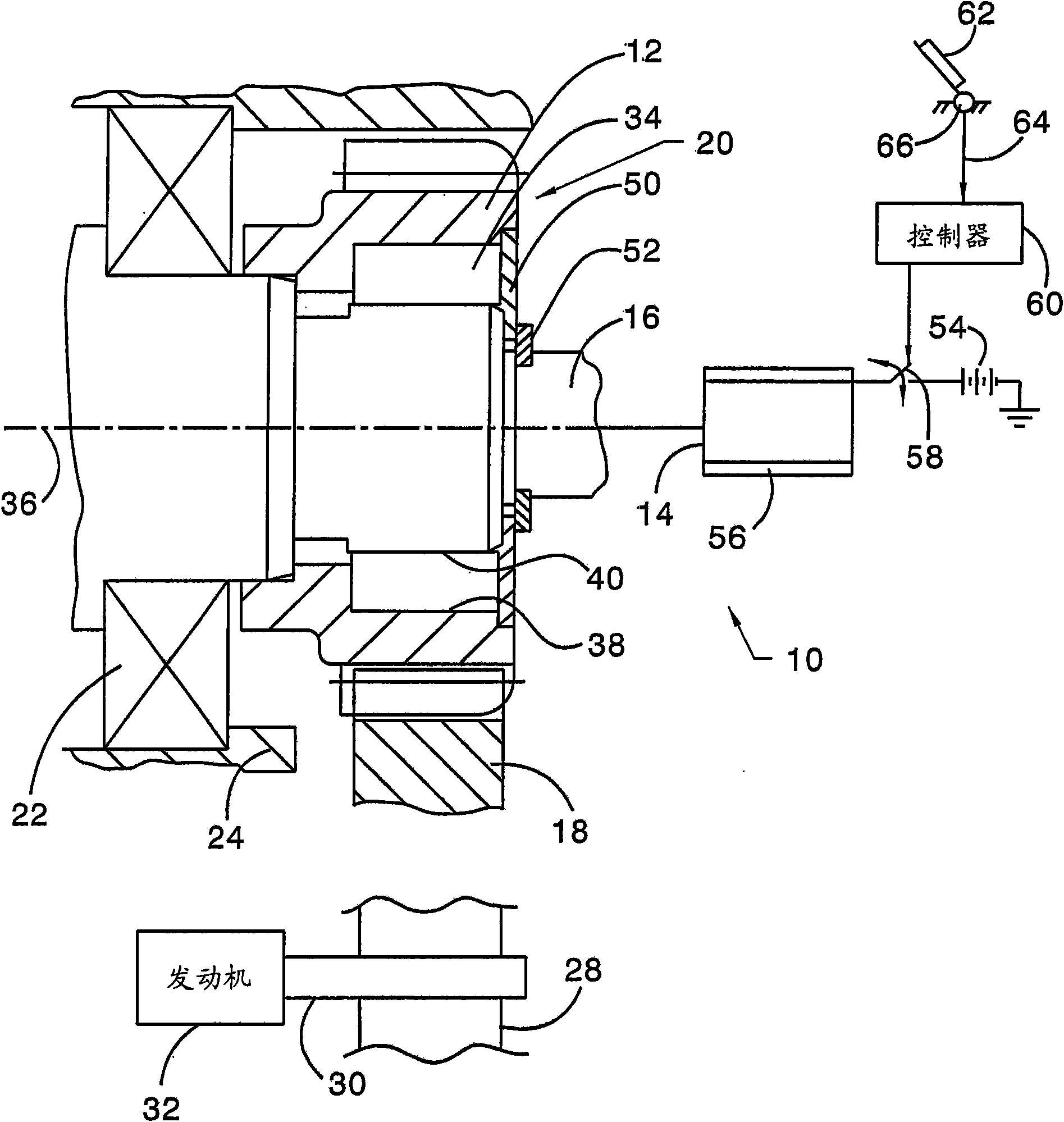

[0018] see now Figure 1-3 , the engine starter system 10 includes: a pinion 12; a starter motor 14; a shaft 16 drivably connected to the motor and the pinion; a ring gear 18 meshing with the pinion; and a one-way clutch (OWC) 20 which Supported on the shaft for alternately breaking and making the drive connection between the shaft and the pinion.

[0019] The shaft 16 is supported for rotation on a bearing 22 fixed to the starter housing 24 and a further bearing 26 at the right-hand side of the pinion 12 .

[0020] The ring gear 18 is formed on a flywheel 28 which is drivably connected to a crankshaft 30 of an engine 32 with an OWC (one way clutch - not shown).

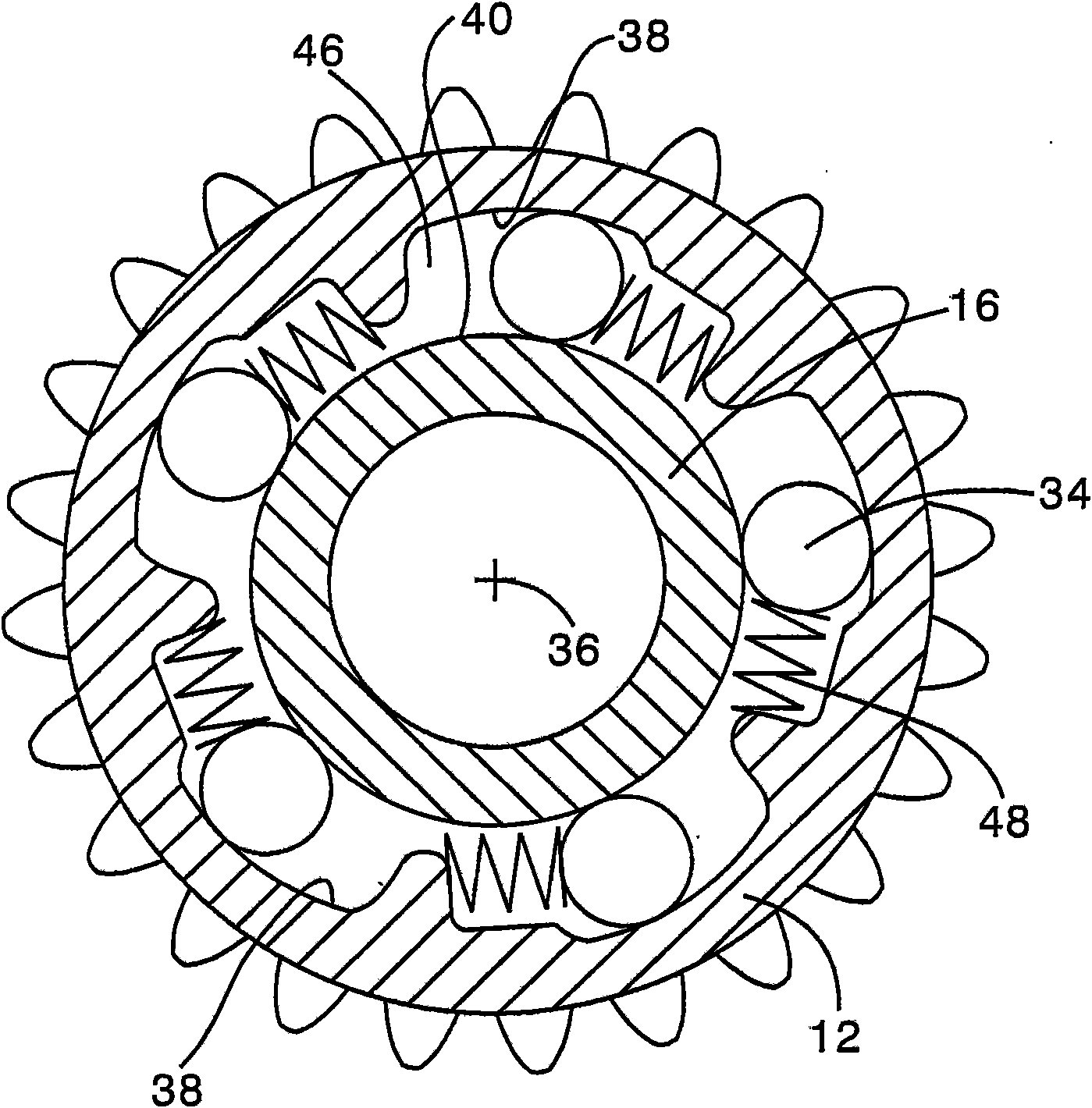

[0021] The one-way clutch 20 includes a set of clutch actuating elements 34 preferably in the form of rollers or balls spaced from each other about an axis 36 . Each clutch element 34 is located within an annular space defined by a slightly radially inclined outer surface 38 formed on the pinion 12 and an inner cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com