Bolt device being quickly fastened and disassembled

A bolt and fastening technology, applied in the field of bolt devices that can be fastened and disassembled, can solve problems such as connection and fixation of large components and supplementary clamping force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

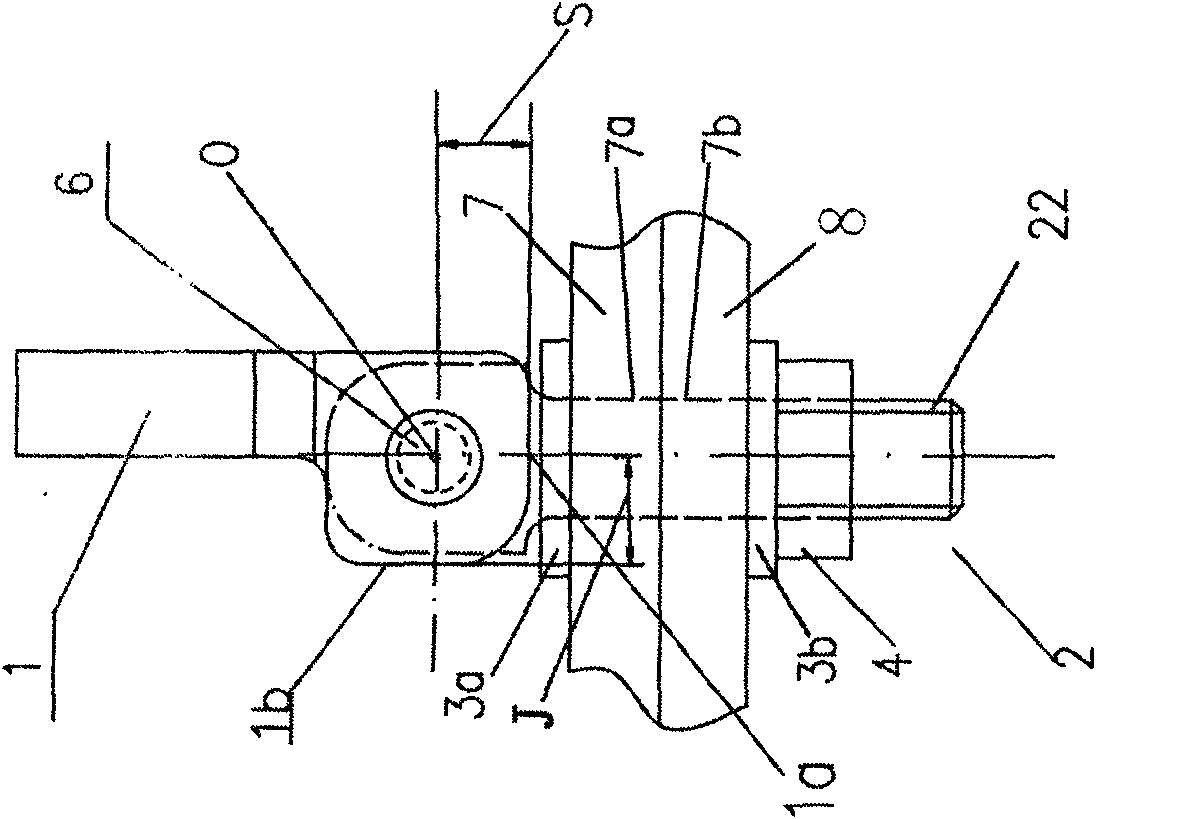

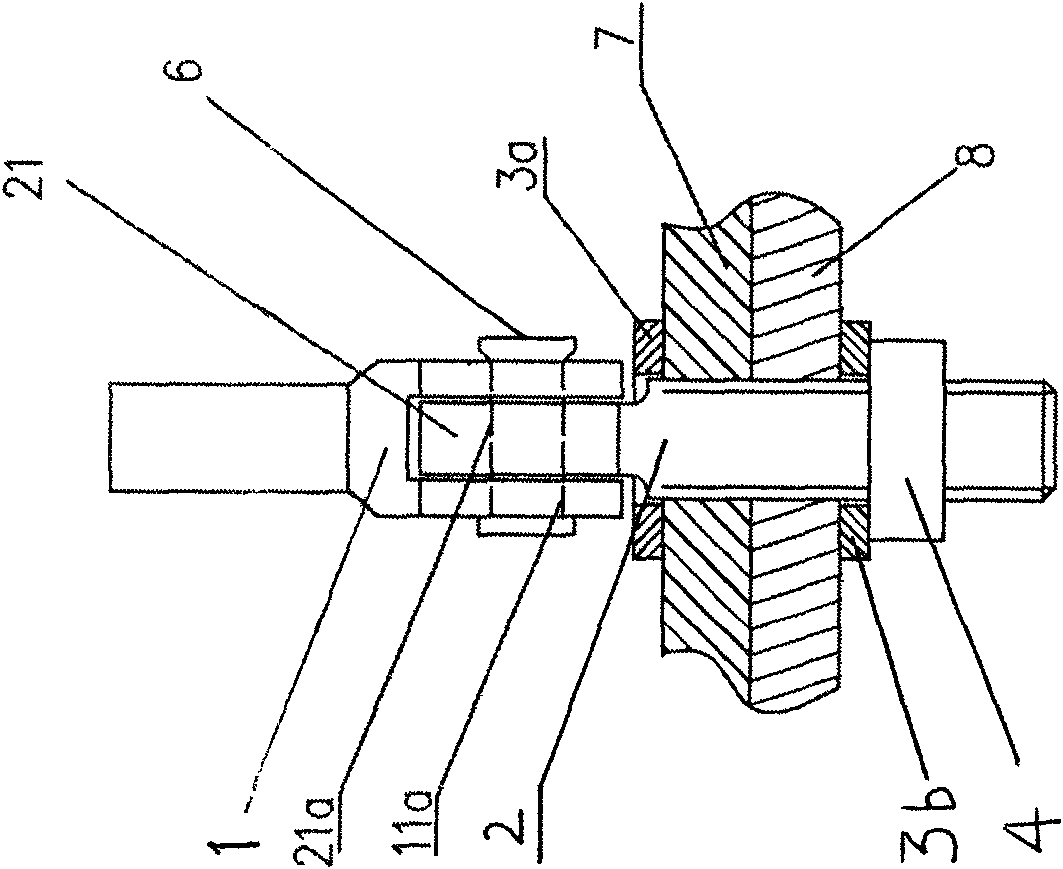

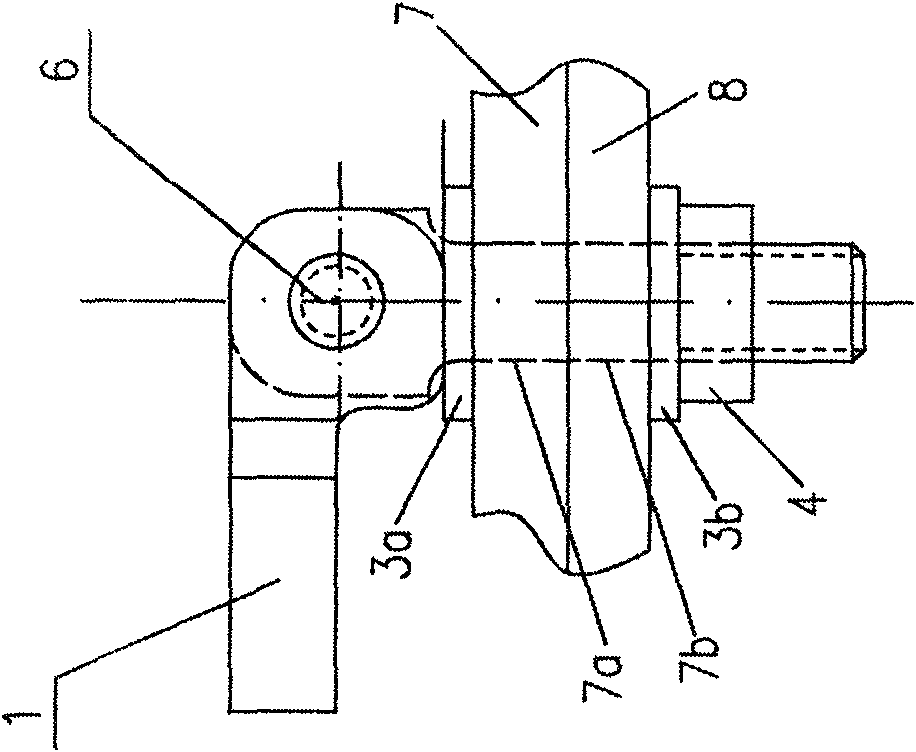

[0020] Such as figure 1 , 2 As shown, the fast fastening bolt device of the present invention includes a bolt 2 , a nut 4 that can be tightened on the bolt 2 and a crimping head 1 for fastening the bolt 2 .

[0021] Wherein, the bolt 2 consists of a threaded screw rod 22 and a flat bolt head 21 connected with the screw rod 22, figure 2 The left and right sides of the middle bolt head 21 extending axially are roughly rectangular (see figure 1 Shown by the dotted line in the center), a bolt pin hole 21a extending perpendicular to the axis of the screw rod 22 is provided on it.

[0022] Such as figure 2 As shown, the crimping head 1 is composed of a crimping head connecting part 11 and a crimping head rod part 12, wherein the cross section of the crimping head connecting part 11 is an inverted U shape, and a crimping head pin hole 11a corresponding to the bolt pin hole 21a is provided on it, through which Insert the flat bolt head 21 into the connection part 11 of the inver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com