Vacuum cleaner

A vacuum cleaner and dust collection technology, applied in the direction of vacuum cleaners, suction filters, cleaning equipment, etc., can solve the problems of affecting the work of the display, poor production process of the compression spring, distortion, etc., to achieve the valve plate stiffness is easy to ensure, reduce the action The effect of bad and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0033] The working principle of the vacuum cleaner of the present invention is the same as that of the prior art, and the prior art can be referred to, so it will not be described again, and the same symbols as those of the prior art will be used. The difference between the present invention and the prior art is that the structure of the display is different , as detailed below:

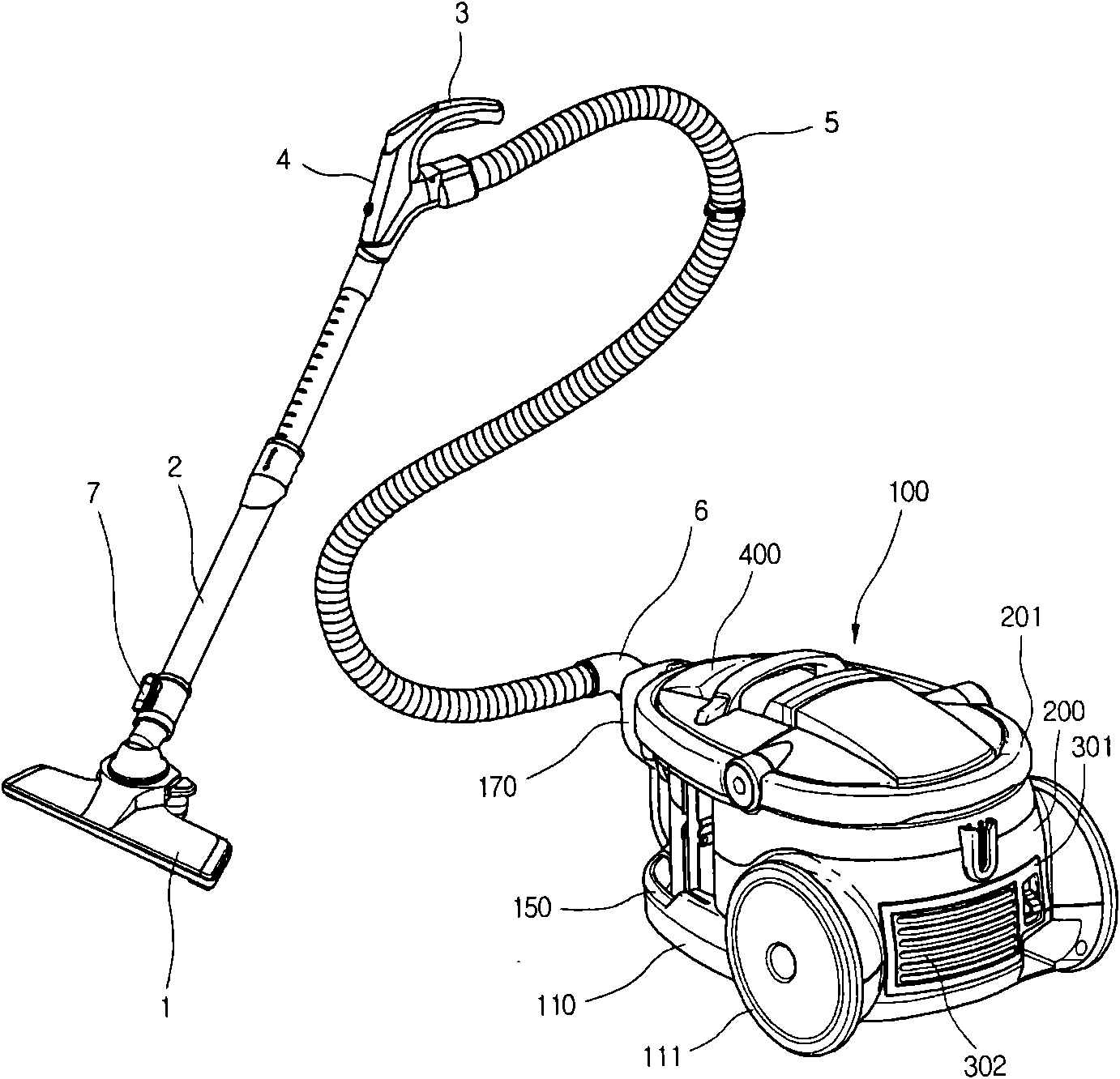

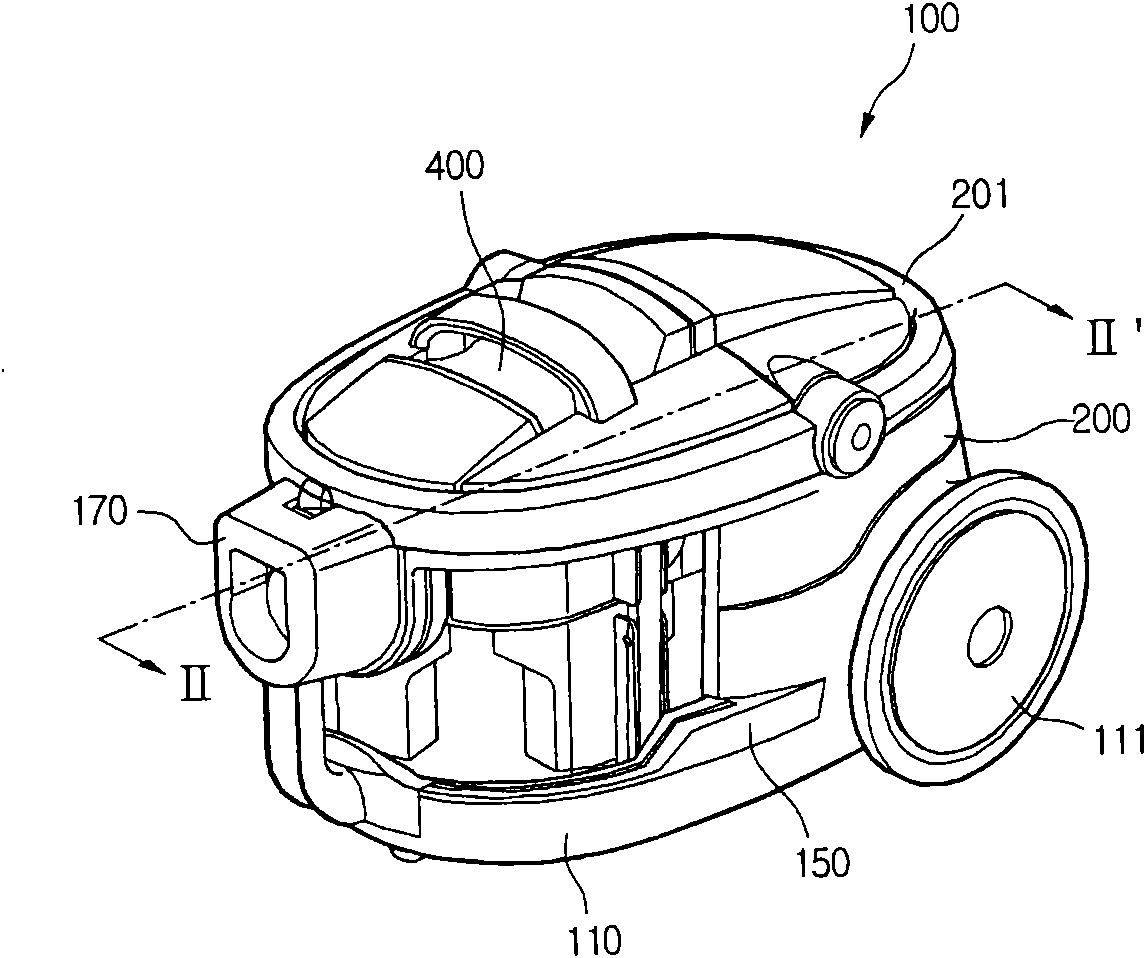

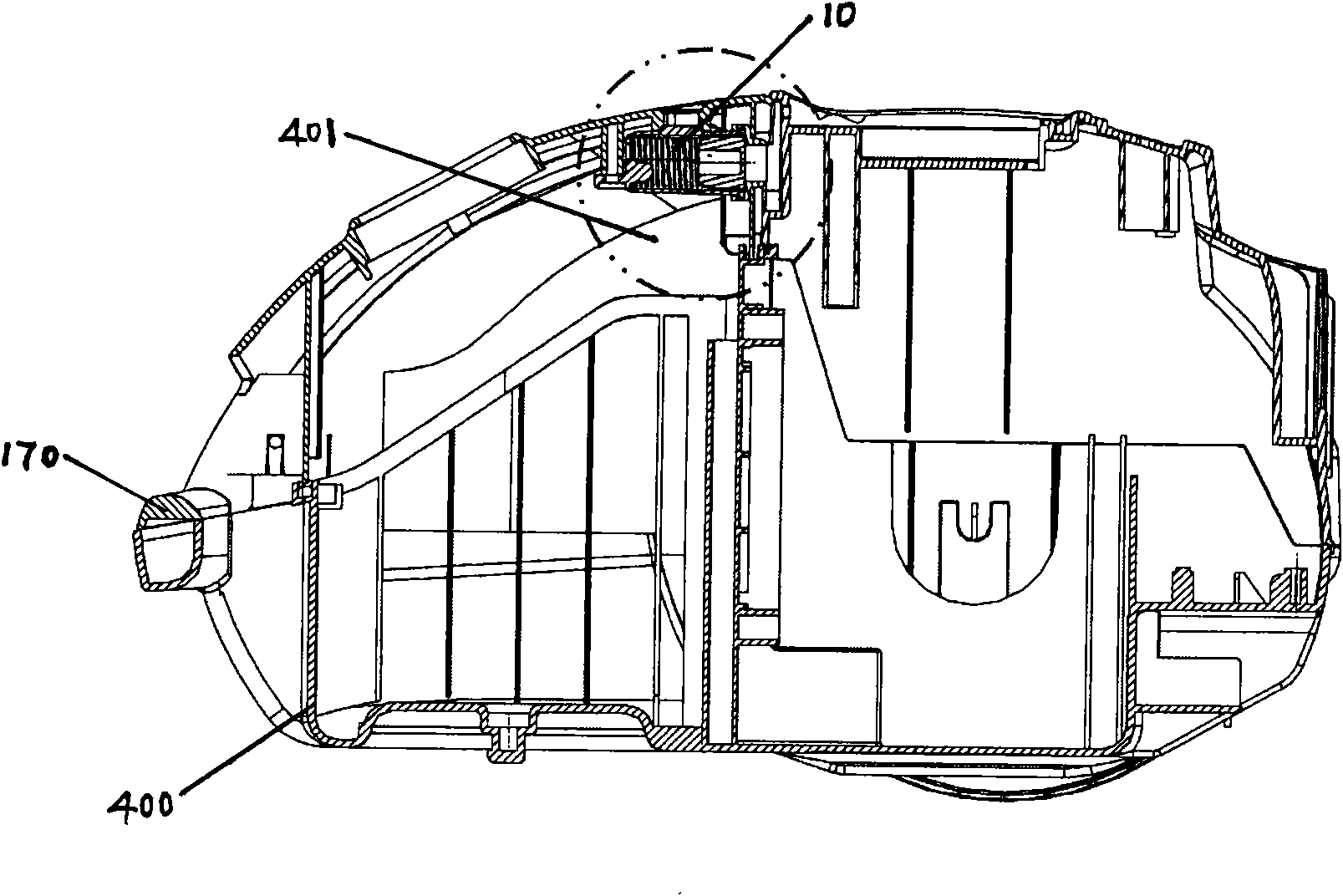

[0034] Such as figure 1 As shown, the vacuum cleaner of the present invention includes: a body 100 ; and a suction pipeline connected to the suction side of the body 100 . A fan and a dust collection unit 400 are provided inside the body 100 to send clean air to the outside after filtering out foreign objects in the air.

[0035] The suction line is a line for sucking in air and foreign matter using the suction force of the body 100 . Specifically, the suction pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com