Double vacuum sucker lifting appliance

A vacuum suction cup and double vacuum technology, applied in the field of spreaders, can solve problems such as delayed work, leakage, accidents, etc., and achieve the effects of ensuring normal work, enhancing adsorption capacity, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

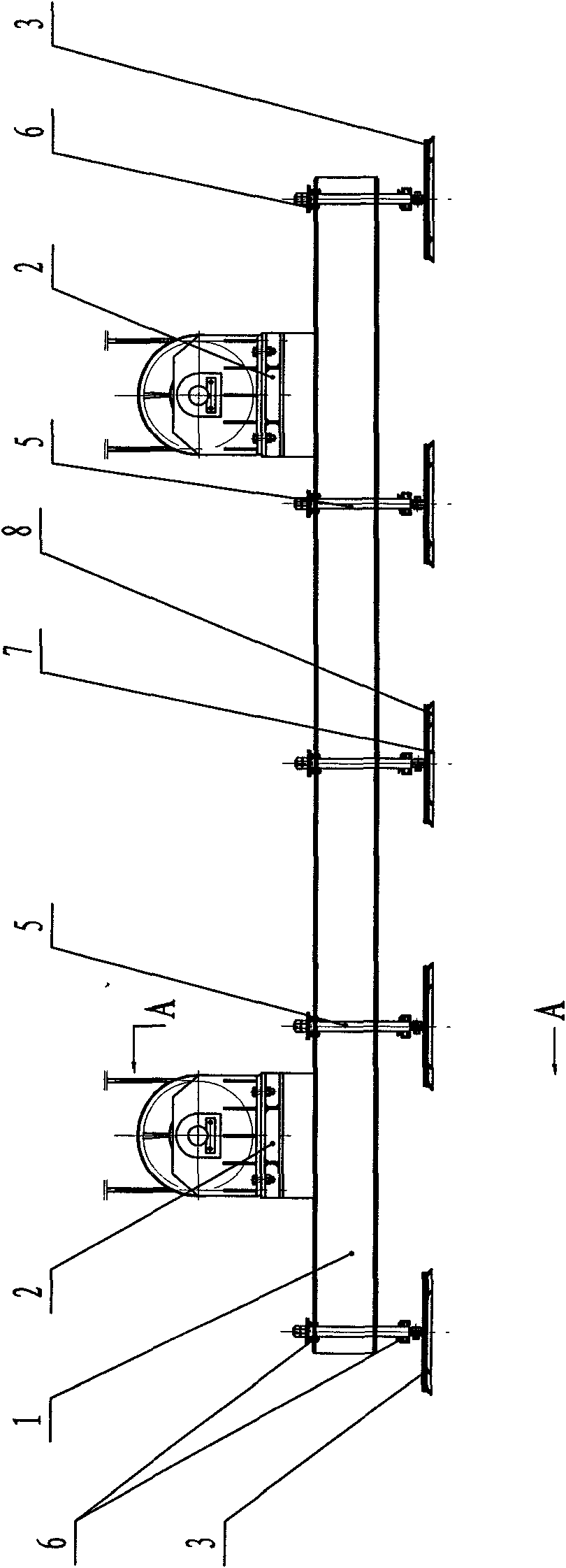

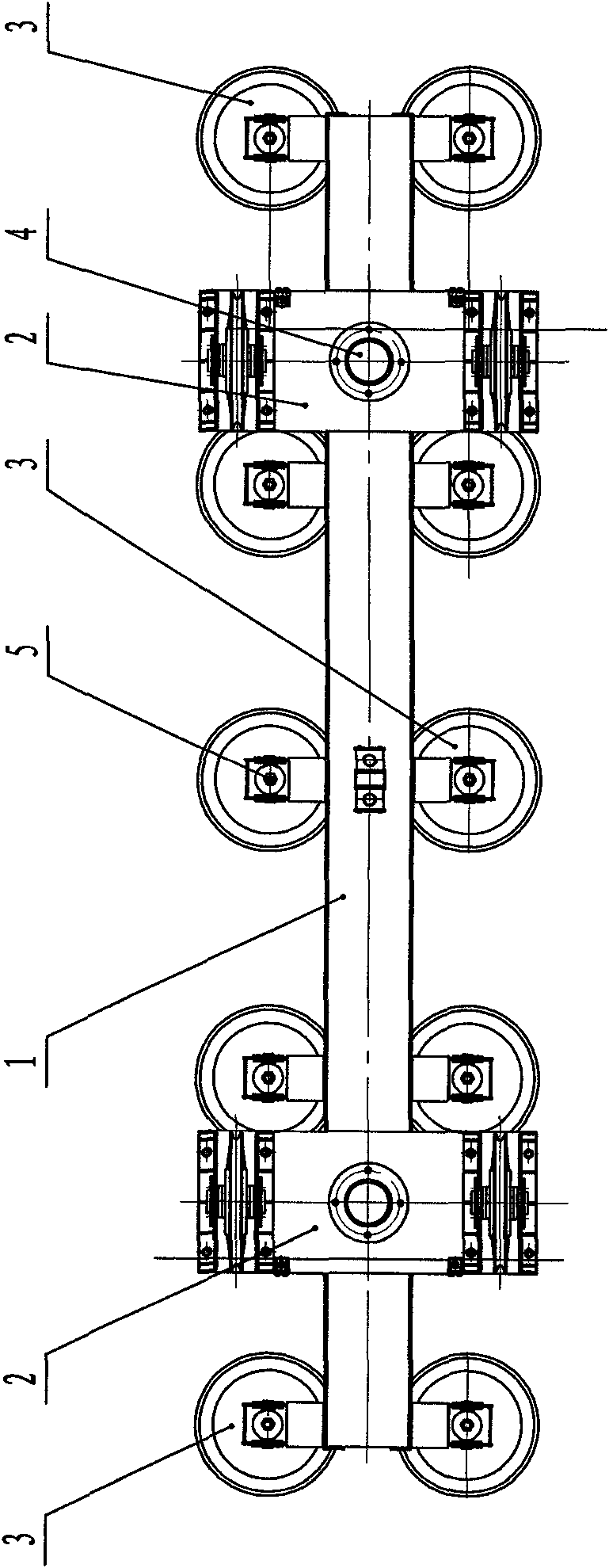

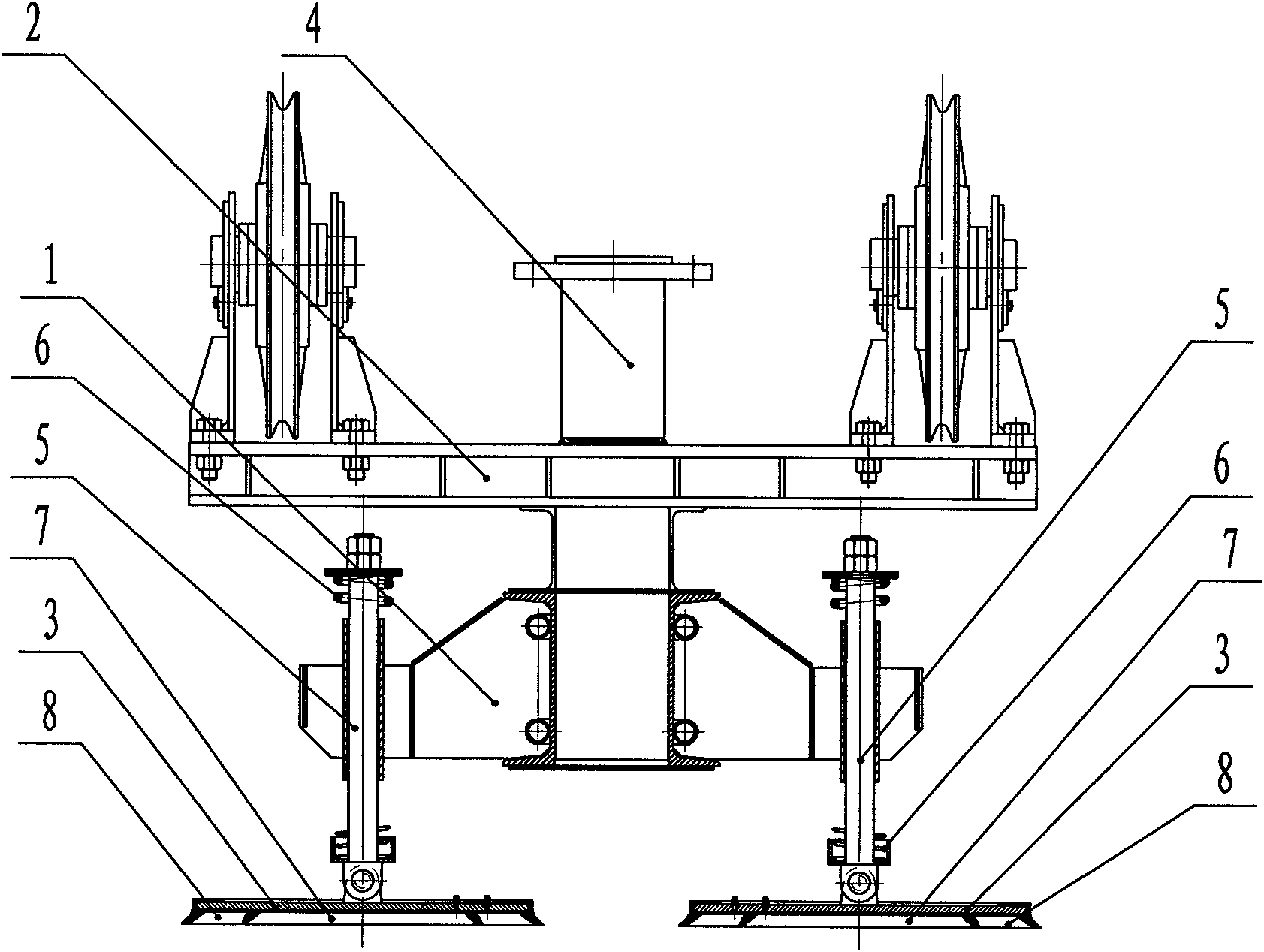

[0017] The double vacuum suction cup spreader includes a hanger 1, the left and right sides of the hanger 1 are fixed with a hanger 2 with movable pulleys, the hanger 1 is provided with a vacuum suction cup device, and the vacuum suction cup device includes a suction cup body 3 and The buffer pillar 5 hinged with the suction cup body 3, the buffer pillar 5 includes a guide post and a buffer spring 6 that is sleeved on the upper and lower sides of the guide post, the guide post between the two buffer springs 6 is placed on the hanger 1, and the bottom of the suction cup body 3 The end face is set as a double-lip structure, and the central cavity 7 and the annular cavity 8 formed by the suction cup body 3 are provided with vent holes respectively communicated with the two vacuum pumps through pipelines. The vent hole of the central chamber 7 of the sucker body 3 communicates with one end of the electromagnetic vacuum three-way valve I 19, and the other end of the electromagnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com