Expansion tube type liner hanger

A liner hanger and expansion tube technology, which is applied in the field of oil drilling, can solve problems such as complex operation, liner falling off, and sealing failure, and achieve the effects of improving cementing quality, improving fluidity, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

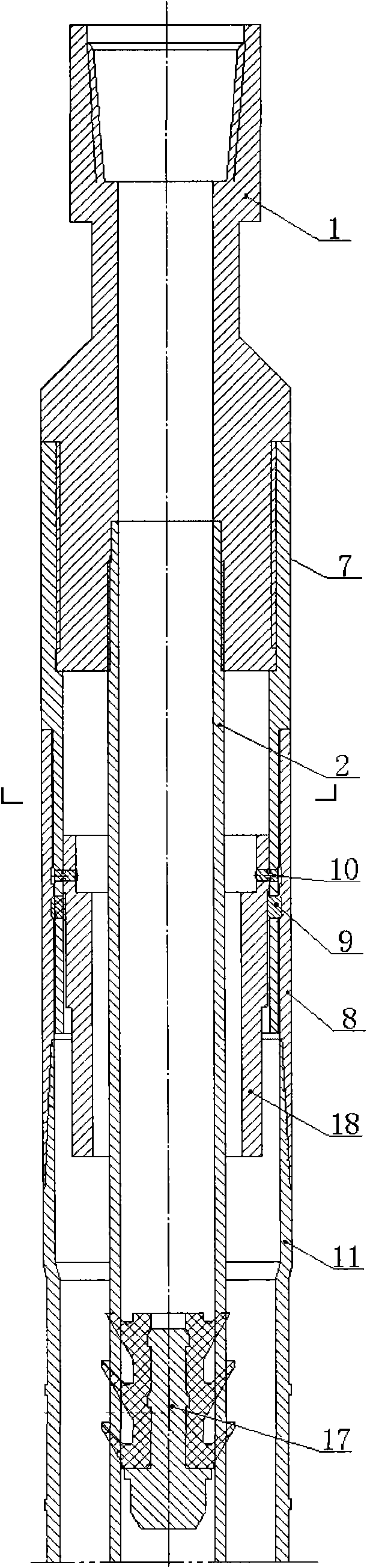

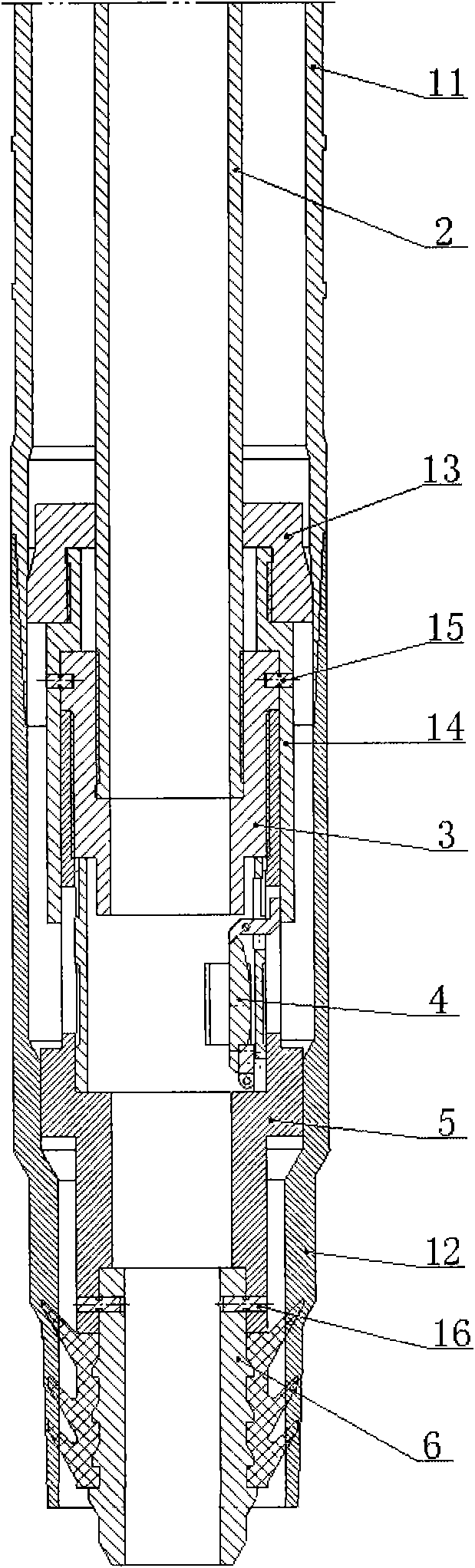

[0042] Example 1: Take one in 9 5 / 8 "Suspend 7" casing in the technical casing, and the used expansion tube type liner hanger is an example, and the invention is described in further detail. The outer diameter of the expansion cone 13 is 195 mm, that is, the inner diameter of the expansion tube 11 is 195 mm after the operation is completed.

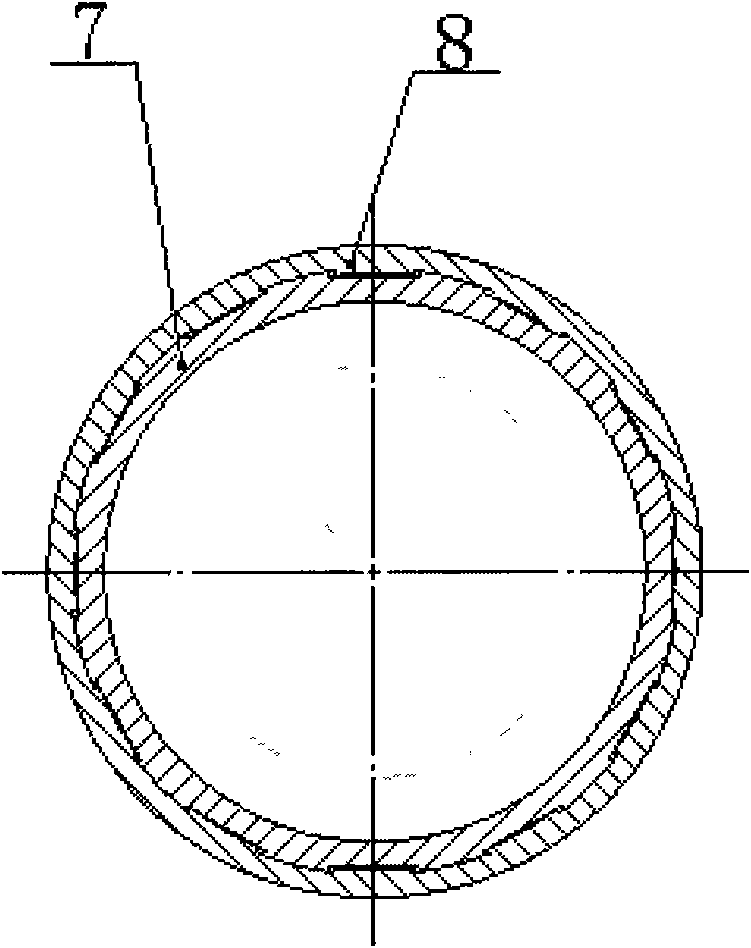

[0043] refer to figure 1 . The expansion tube type tail pipe hanger of the present invention is mainly composed of a feeding joint 1, a center pipe 2, a nut 3, a float valve assembly 4, a tail pipe rubber plug hanger 5, a tail pipe rubber plug 6, a muff 7, Spline sleeve 8, key 9, shear pin 10, expansion pipe 11, tie-back cylinder 12, expansion cone 13, float valve closing sleeve 14, pin 15, shear nail 16, drill pipe rubber plug 17 and top sleeve 18 . The feed-in joint 1 has a central hole, and the top of the feed-in joint 1 has an internal thread, which can be connected to the upper drill pipe during construction.

[0044] The low...

Embodiment 2

[0056] Embodiment 2: The difference from Embodiment 1 is that the cross-section of the annular boss on the outer wall of the expansion tube 11 is triangular.

Embodiment 3

[0057] Embodiment 3: The difference from Embodiment 1 is that the section of the annular boss on the outer wall of the expansion tube 11 is trapezoidal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap