Shock absorption structure on electric car coupler

A technology for electric vehicles and couplings, applied in couplings, elastic couplings, rotational vibration suppression, etc., can solve the problem of limited vibration improvement effect, difficult to meet the requirements of use, and the coupling cannot absorb the vibration of the motor and transmission Energy and other problems, to achieve the effect of simple and reliable structure, excellent shock absorption performance, and avoid damage to parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

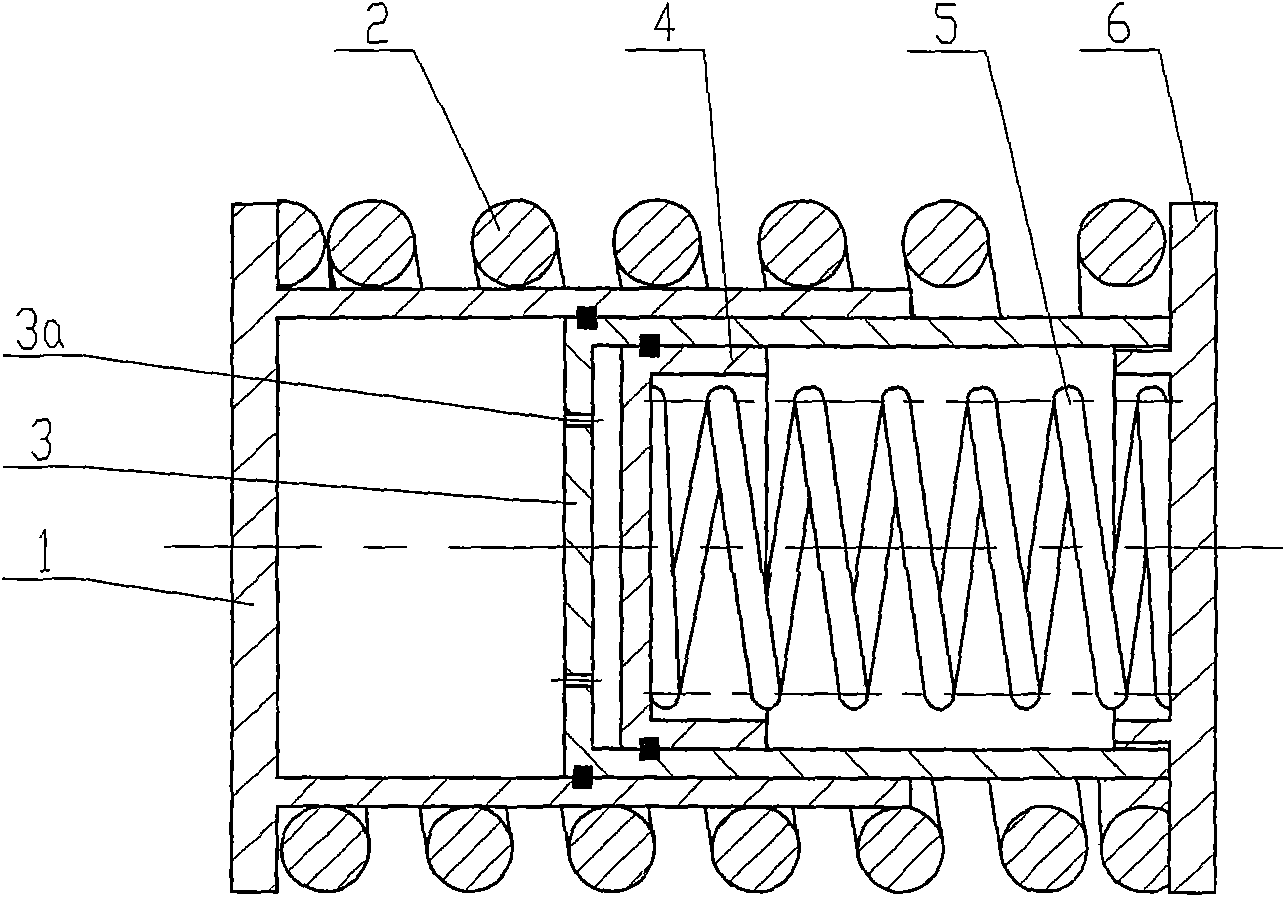

[0013] Such as figure 1 As shown, the present invention is made of oil cylinder 1, outer spring 2, first piston 3, second piston 4, inner spring 5 and end cap 6, wherein oil cylinder 1 is a cylindrical structure with one end closed and the other open. The outer edge of the closed end extends outward to form a disc body. The first piston 3 is a cylindrical structure, the closed end of the first piston 3 protrudes into the oil cylinder 1 , and a throttle hole 3 a is opened on the closed end of the first piston 3 . The open end of the first piston 3 is sleeved on the annular boss in the middle of the end cover 6 , and the two are threadedly matched, and the end cover 6 seals the open end of the first piston 3 . Set outer spring 2 on oil cylinder 1 and first piston 3, one end of this outer spring 2 is limited by the disc body of oil cylinder 1 closed end outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com