Backflow preventer

A technology of backflow preventer and flow channel wall, which is applied in the direction of valve details, control valves, function valve types, etc., can solve problems such as inability to form effective checks, inability to realize online maintenance, and affect system efficiency, so as to ensure stability, Low manufacturing cost, simple installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] This embodiment is used to explain the claims of the invention, and the protection scope of the invention is not limited to the structures described below. Those skilled in the art make structural changes different from the following in the technical solution of the present invention, all of which belong to the protection scope of the present invention.

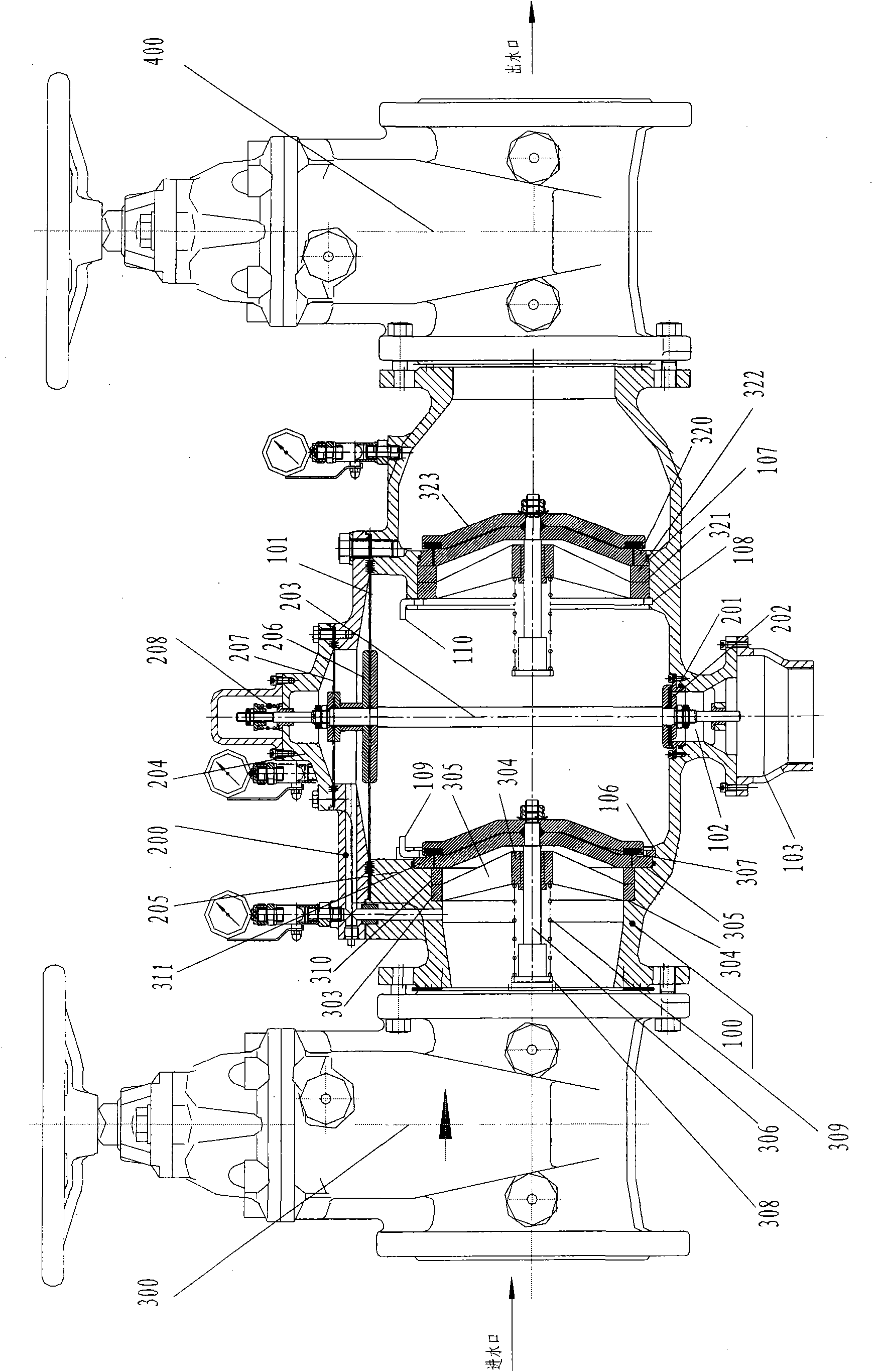

[0015] Such as figure 1 As shown, the water inlet end and the water outlet end of the valve body 100 are respectively connected with valves 300 and 400 for maintenance. When online maintenance is required, the maintenance valves 300 and 400 can be closed.

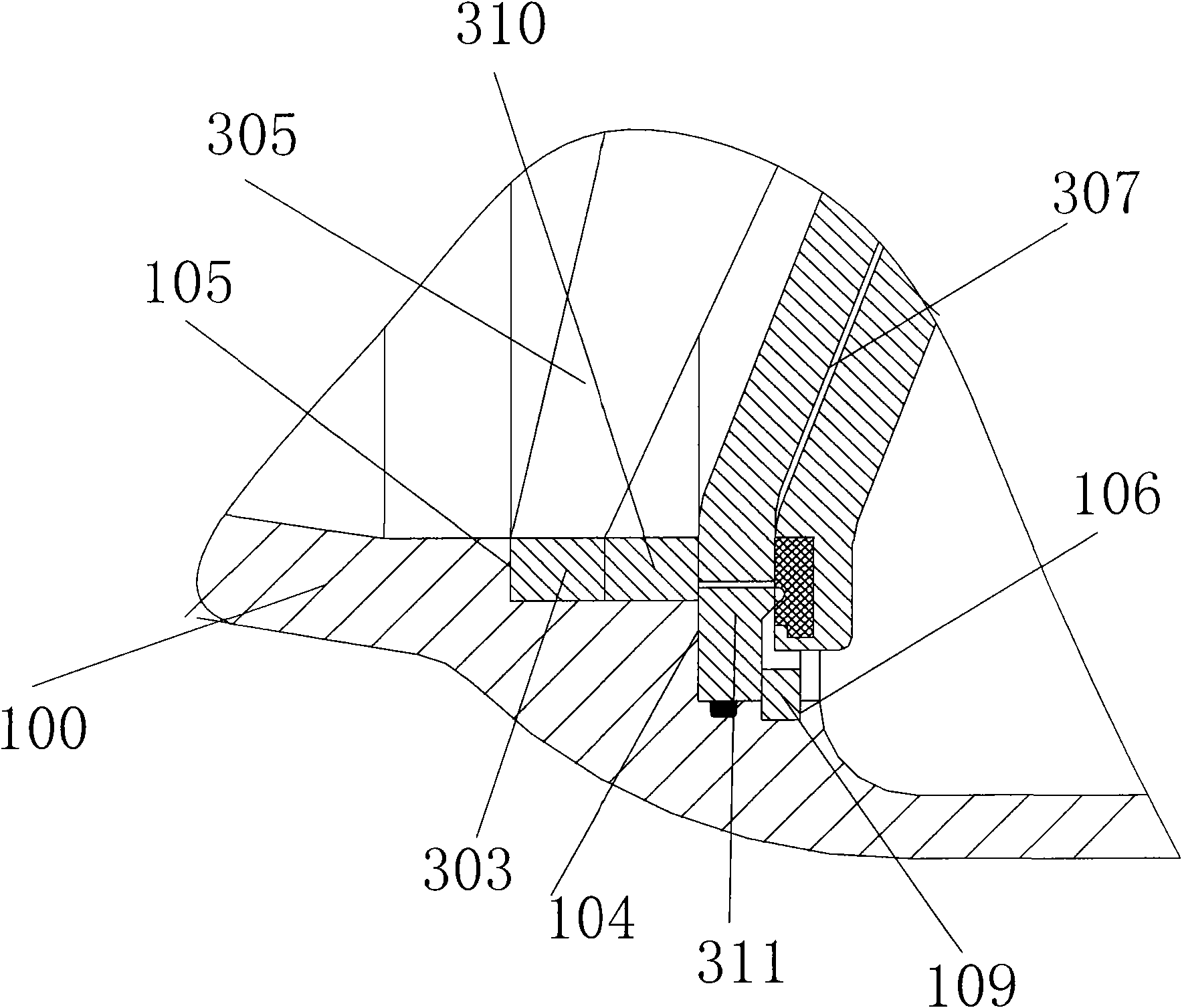

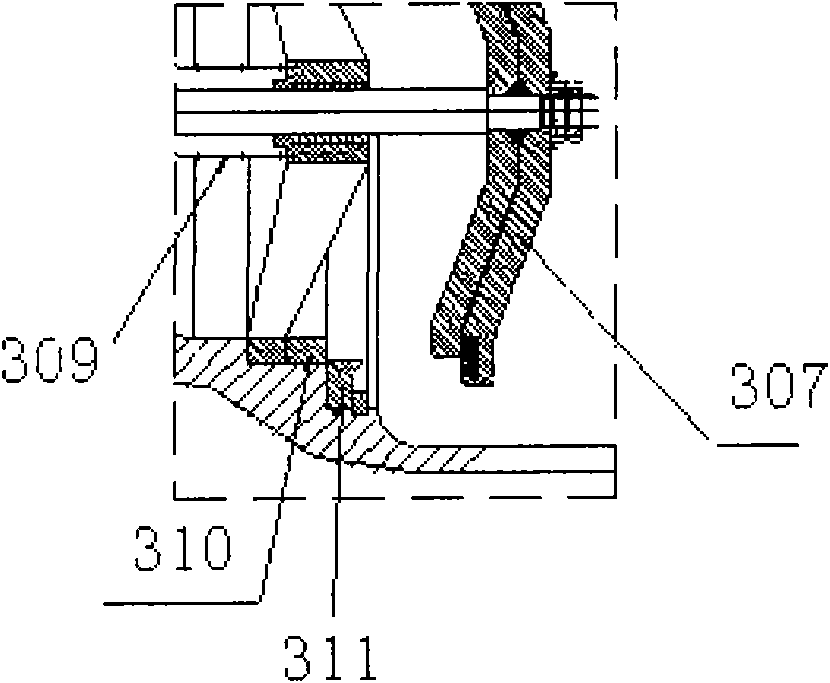

[0016] The upper part of the valve body 100 is provided with a maintenance hole 101 , and the lower part is provided with a drain port 102 . The valve body 100 at the inspection hole 101 is connected to the valve cover 200 , and the drain port 102 is connected to the leaking funnel 103 . Detachable check valve assemblies 301 and 302 are respectively arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com