Method for continuously monitoring appearance of continuous casting sheet billet online

A thin slab and billet technology, which is applied in the field of online continuous monitoring of the appearance and shape of continuous casting thin slabs, can solve problems such as time delay, lack of data support, collision with side guide plates, etc., and achieve the effect of avoiding equipment accidents and out-of-standard products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

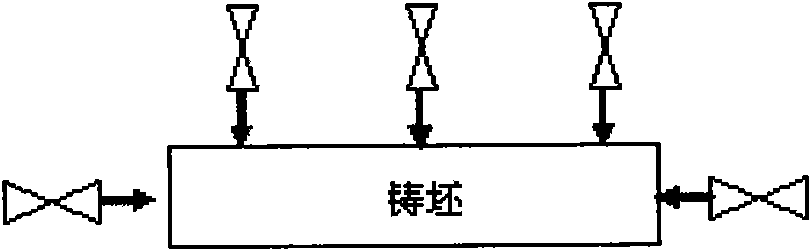

[0012] In the horizontal air-cooling section of thin slab continuous casting, a high-precision infrared rangefinder is used to measure the sickle and wedge values of the slab. The setting position of the range finder is that one group is set on both sides of the thin slab roller table, each group is 2 pieces, and each group of range finder is on a straight line parallel to the roller row, and the distance from the casting slab is less than 2000mm; the casting slab One group is arranged above, is 3. The data collection frequency of all rangefinders is 2 pieces / s, and the distance measurement accuracy is ≤±1mm.

Embodiment 2

[0014] In the horizontal air-cooling section of thin slab continuous casting, a laser range finder is used to measure the camber value and wedge value of the slab. The setting position of the range finder is that a group is set on both sides of the thin slab roller table, each group is 2 pieces, and each group of range finder is on a straight line parallel to the roller row, and the distance from the casting slab is less than 2000mm; the casting slab Set one group above, be 2. The data collection frequency of all rangefinders is 6 pieces / s, and the distance measurement accuracy is ≤±1mm.

Embodiment 3

[0016] In the horizontal air-cooling section of thin slab continuous casting, a high-precision infrared rangefinder is used to measure the sickle and wedge values of the slab. The setting position of the range finder is that a group of 3 sets are arranged on both sides of the thin slab roller table, and each group of range finder is on a straight line parallel to the roller row, and the distance from the casting slab is less than 2000mm; the casting slab One group is arranged above, is 4. The data collection frequency of all rangefinders is 9 pieces / s, and the distance measurement accuracy is ≤±1mm.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap