Compensation method of radius of tool for triaxial numerical control machine based on curve surface reconstruction

A tool radius and CNC machine tool technology, which is applied in the direction of program control, computer control, general control system, etc., can solve the problems of inability to perform tool compensation on-line and loss of geometric information on the processed surface, so as to achieve good promotion and application prospects, improve production efficiency, The effect of improving calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

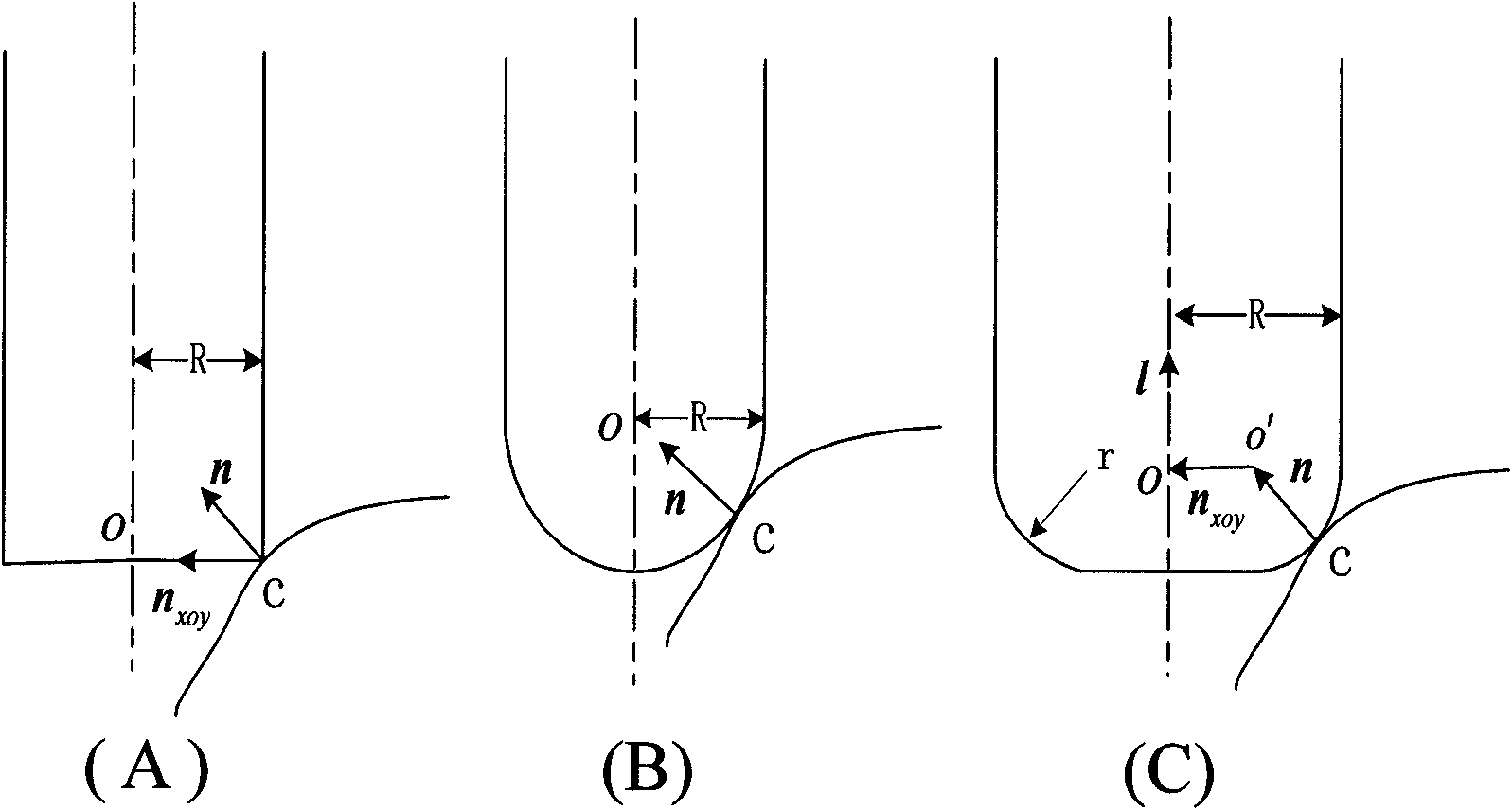

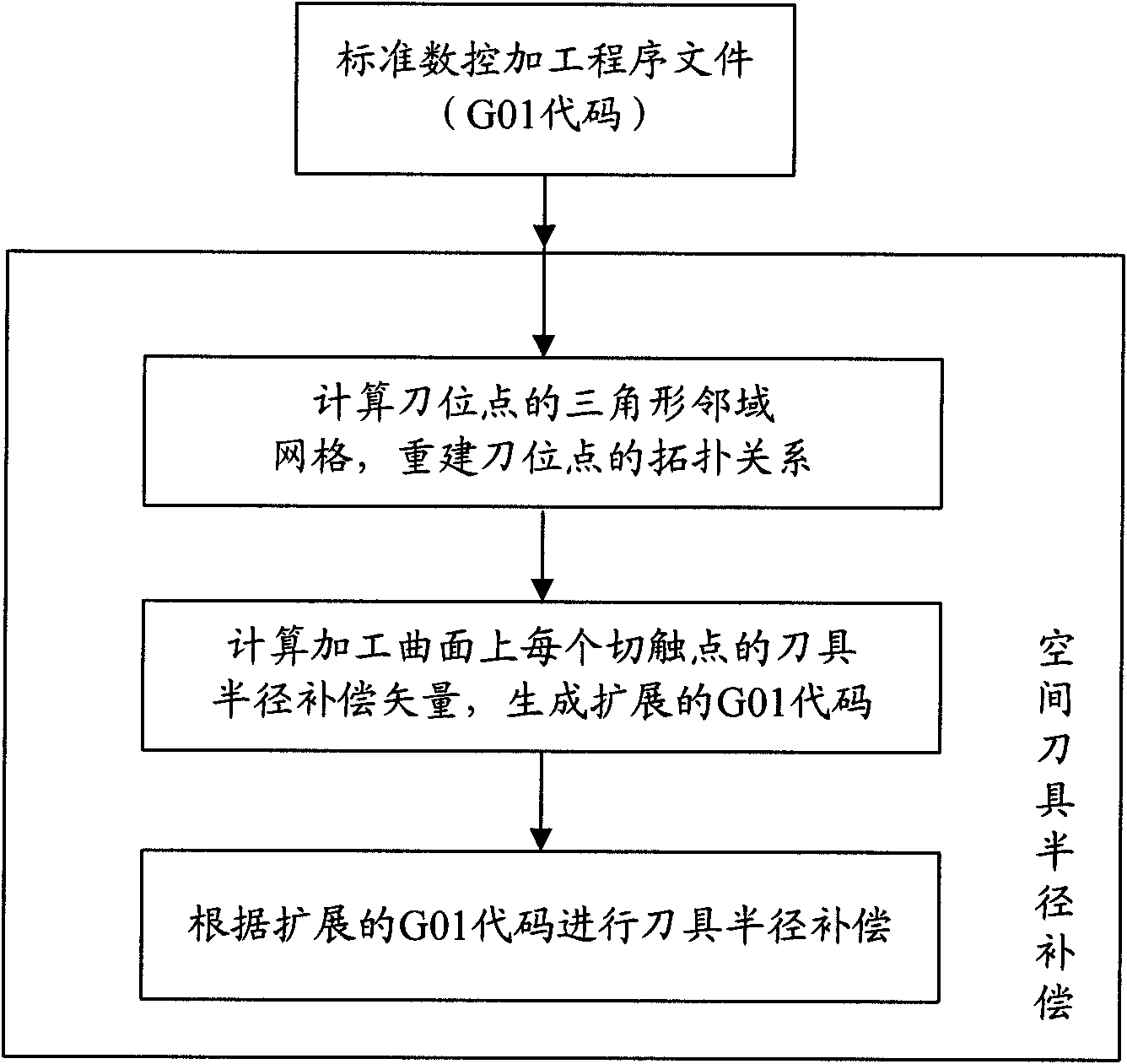

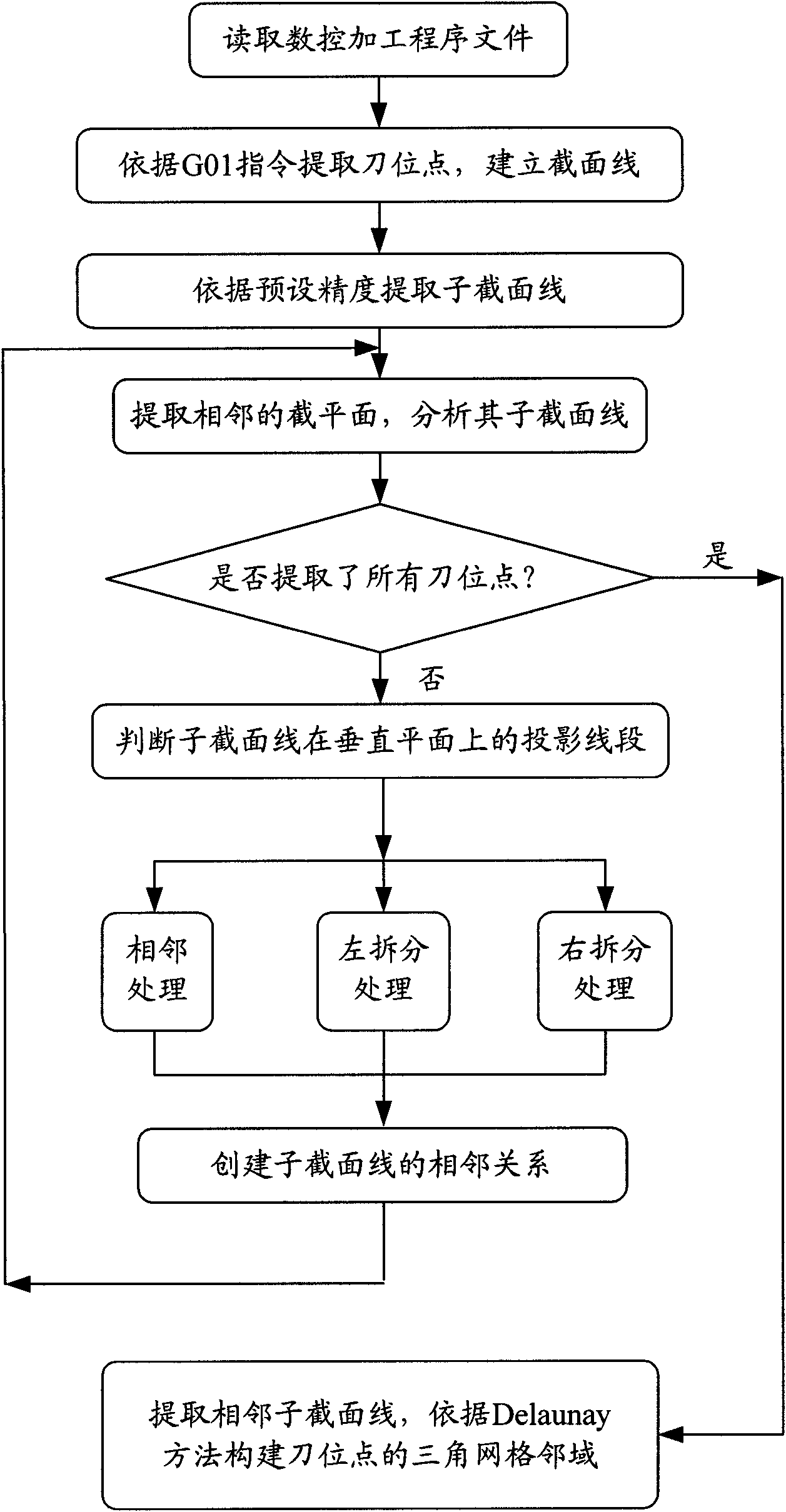

[0014] The invention is a tool radius compensation method for a three-axis CNC machine tool based on curved surface reconstruction in a numerical control system. The method generates a tool path based on the sectional plane method, that is, the tool position trajectory is planned on a group of parallel planes (usually a group of On the plane perpendicular to the xoy plane), the NC machining program with compensation parameters is generated through post-processing; the specific method is: first analyze the G01 code in the NC machining program, extract all the tool points, and realize the machining surface where the tool points are located After the quick reconstruction of , calculate the unit normal vector of each tool position point on the surface where the tool po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com