Flow control device for steel ball flaw detection

A technology of flow control device and steel ball, which is applied in the flow control of electric devices, etc. It can solve the problems that steel balls are easily magnetized, impurities are easy to adhere to the surface, and affect cutting and cleaning efficiency, so as to achieve low power consumption and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

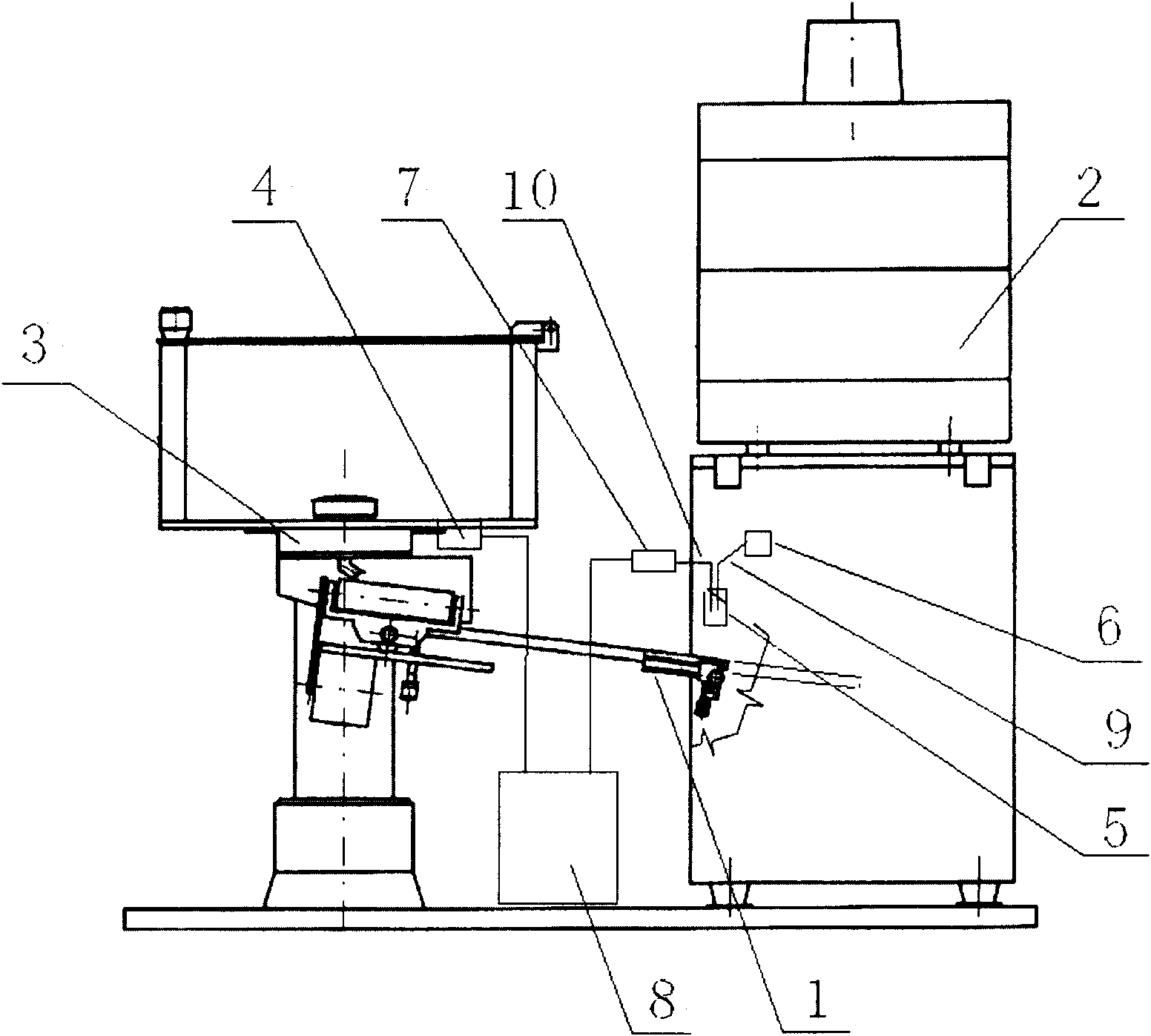

[0007] As shown in the figure, it contains a flow ball bridge 1, an eddy current detection device 2, a ball ejector 3, a ball switch 4, an optical fiber probe 5, a light source 6, a photoelectric amplifier 7, and a programmable controller 8.

[0008] One end of the above-mentioned flow ball bridge 1 is connected with the eddy current detection device 2 and the other end is connected with the ball ejector 3, and the ball ejector 3 is provided with a ball ejection switch 4 that controls and stops the ball ejection. The optical fiber detecting head 5 is arranged above the flow ball bridge 1, and two optical fibers 9 and 10 are respectively connected in the optical fiber detecting head 5, and the optical fibers 9 and 10 are connected to the light source 6 and the photoelectric amplifier 7 respectively.

[0009] The photoelectric amplifier 7 is connected to the programmable controller 8, and the other end of the programmable controller 8 is connected to the ball switch 4. We set the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com