Field system

A technology of excitation system and magnetic pole face, applied in the direction of magnetic circuit, magnetic circuit rotating parts, magnetic circuit static parts, etc., can solve the problems of reduced productivity, unable to insert unit magnets, etc., to reduce the necessary accuracy and improve the interlinkage. Magnetic flux, effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

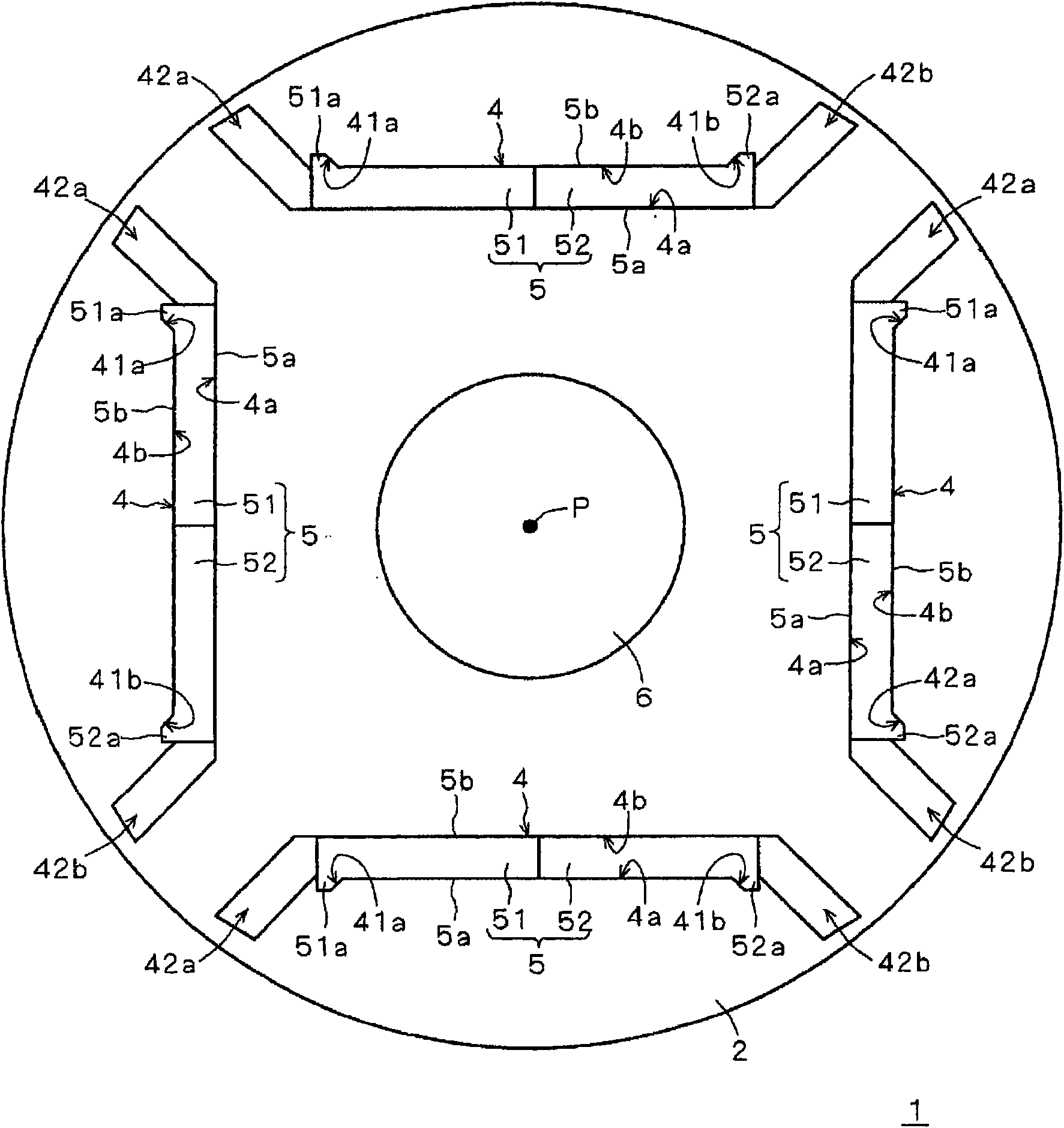

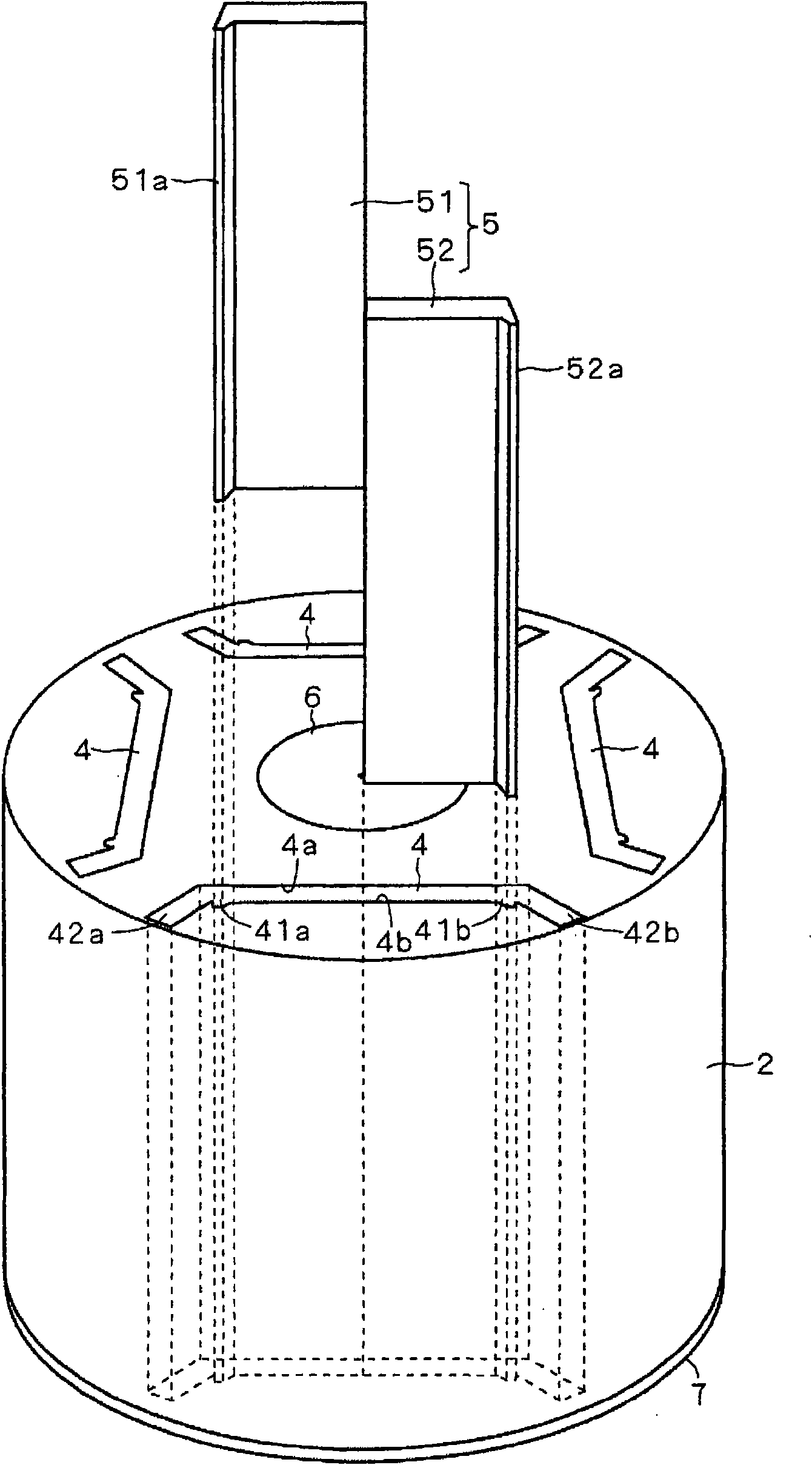

[0040] figure 1 A schematic cross-sectional view showing an excitation system according to a first embodiment of the present invention. figure 1 A schematic configuration of a cross section perpendicular to the rotation axis P of the excitation system 1 is shown. This excitation system 1 has an excitation core 2, a field magnet 5, and an unillustrated end plate.

[0041] Such as figure 1 As shown, the field core 2 has an annular outer periphery centered on the rotation axis P. As shown in FIG. The field core 2 is provided with an insertion hole 4 and a shaft hole 6 . In addition, the field core 2 is made of a magnetic material and extends in a direction parallel to the rotation axis P (direction perpendicular to the paper surface: not shown, hereinafter referred to as the rotation axis direction).

[0042] More specifically, in the field core 2 , a shaft hole 6 is provided in a region including the rotation axis P, and a shaft (not shown) is inserted through the shaft hole...

no. 2 Embodiment approach

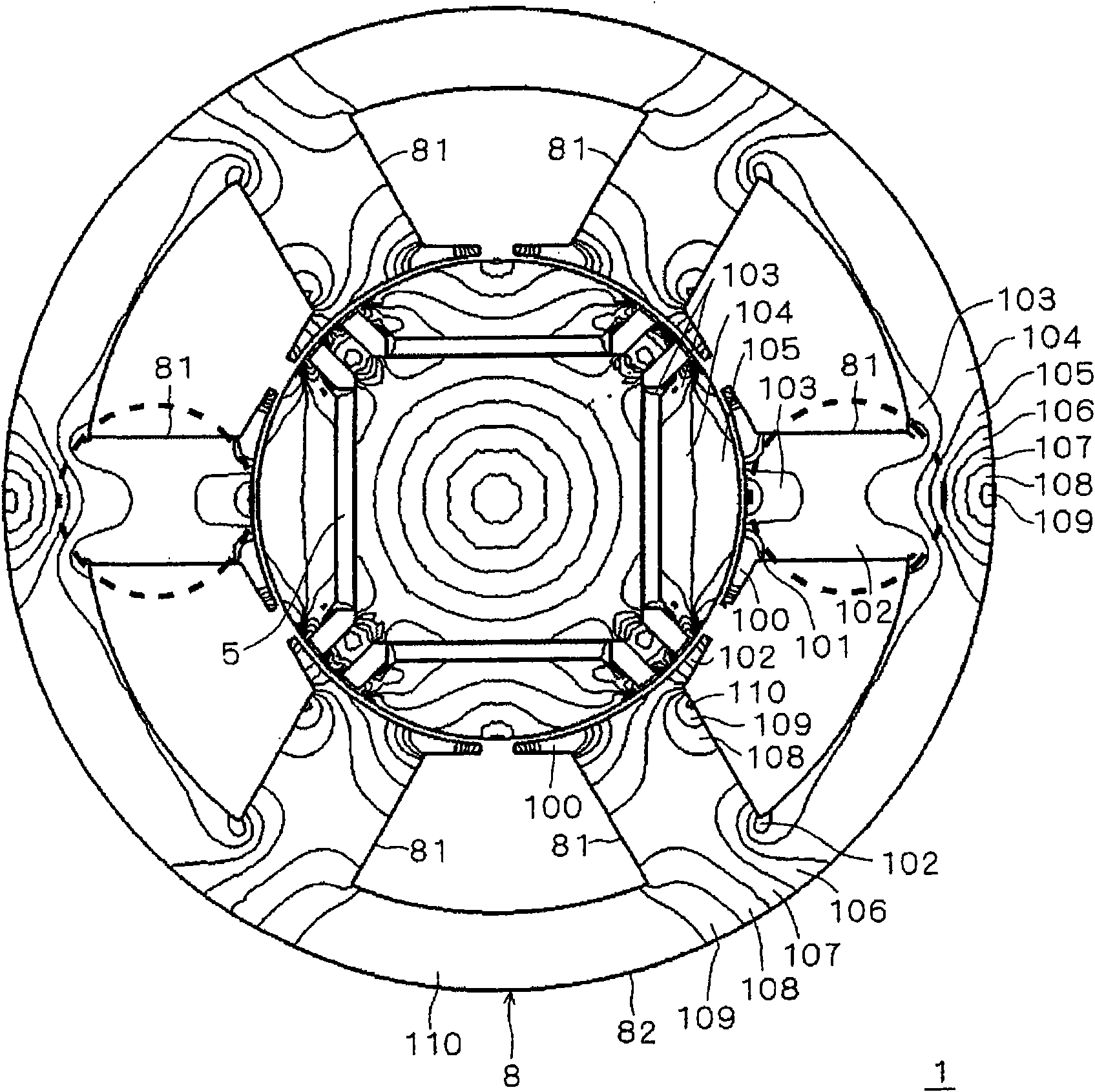

[0069] Figure 13A schematic cross-sectional view showing an excitation system according to a second embodiment of the present invention. Figure 13 A schematic configuration of a cross section perpendicular to the rotation axis P of the excitation system 1 is shown. The exciter system 1 has an exciter core 2 and a field magnet 5 .

[0070] Figure 13 Excitation system 1 shown with figure 1 The exciter system 1 shown differs in that the field magnet 5 is formed by a permanent magnet.

[0071] According to this excitation system 1, the same as used in the first embodiment Figure 3-6 The description is the same, and it is possible to improve the field magnetic flux and the anti-demagnetization force. Furthermore, similarly to the first embodiment, the insertion surfaces 4a, 4b and the magnetic pole surfaces 5a, 5b function as guides for guiding the field magnet 5, so the field magnet 5 can be easily inserted into the insertion hole 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com