Hydraulic safety device for two-roller calender

A safety device, hydraulic technology, applied in the field of overload safety protection device, can solve the problems of equipment damage, uneven thickness, long replacement time of safety sheet, etc., achieve the effect of simple structure and avoid roller damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

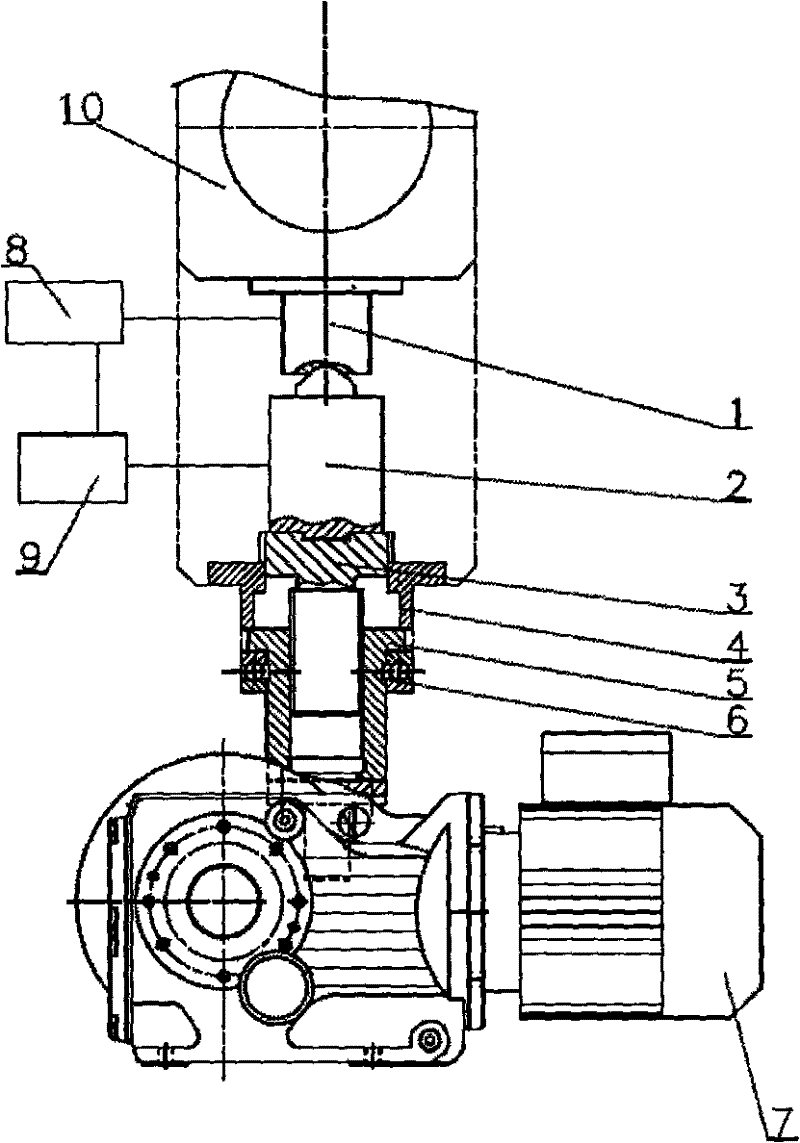

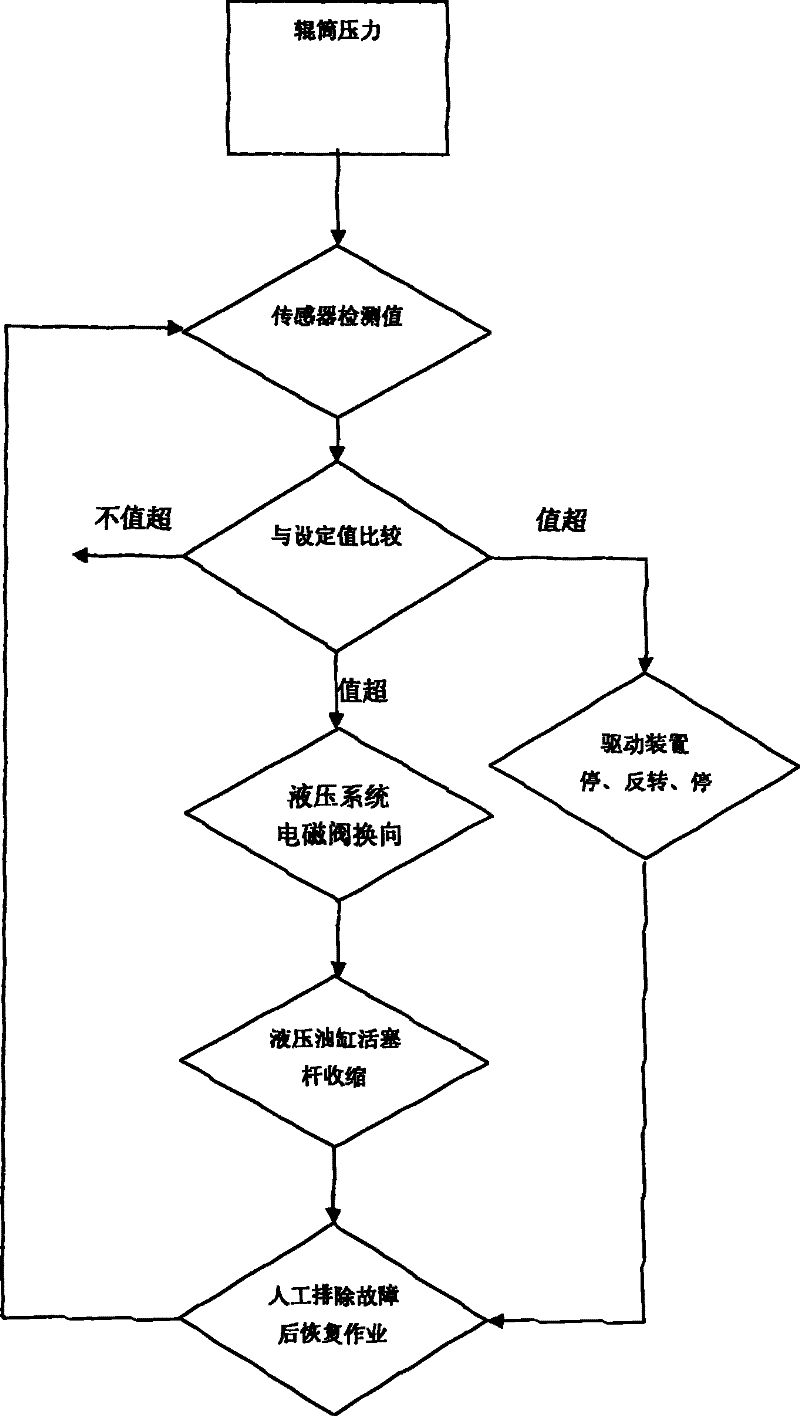

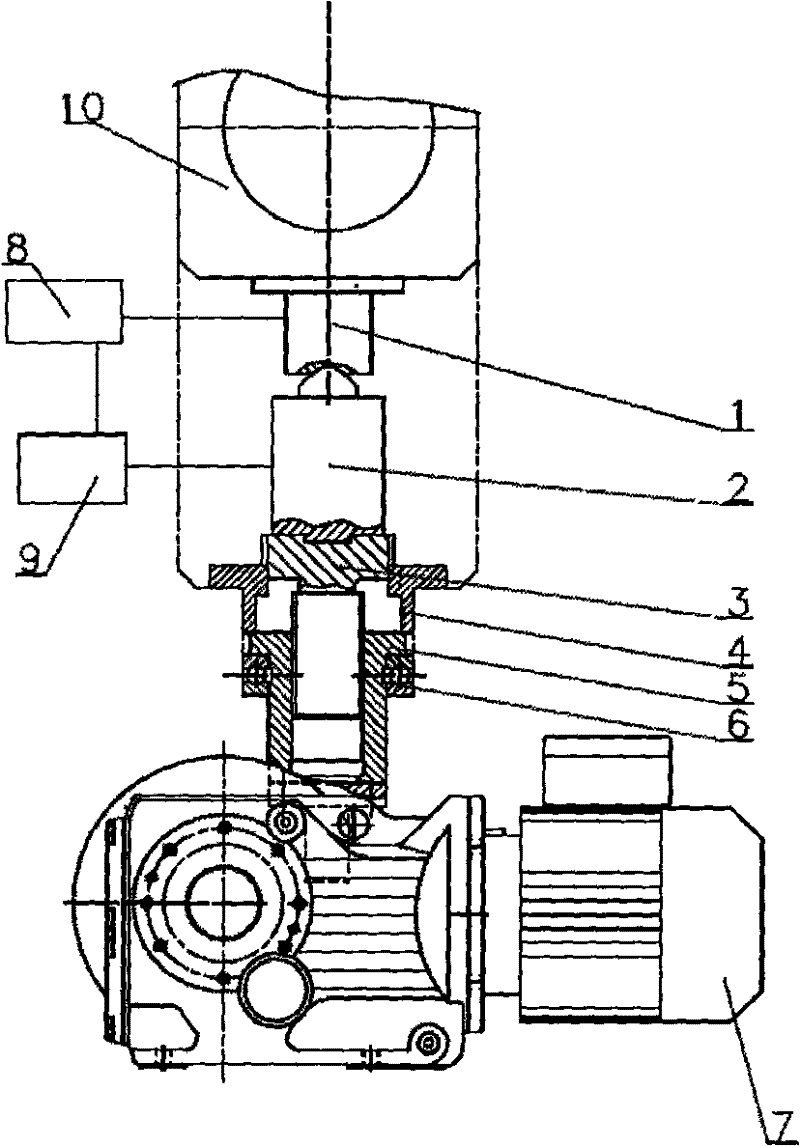

[0015] Such as figure 1 The hydraulic safety device of the vertical two-roll calender shown is composed of a hydraulic cylinder 1, a sensor 2, a hydraulic system 8 and a control system 9. The upper plane of the hydraulic cylinder 1 supports the roller bearing 10 , and the upper ball head of the sensor 2 pushes into the concave spherical surface of the hydraulic cylinder 1 . After the hydraulic cylinder 1 is supplied with pressure oil by the hydraulic system 8, it becomes a rigid body carrying the pressure transmitted to the bearing seat by the roller. After the sensor detects this force, it is converted into an electrical signal and sent back to the control system 9, which is consistent with the preset value in the control system. The safety protection pressure and voltage values in the system 9 are compared, when the detected signal value is less than the set value, it is normal operation, when the detected signal value is greater than the set value, the control system 9 se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com