Plastic suction molding method of large-size plastic plate and large-size plastic sucking machine of large-size plastic plate

A plastic sheet and blister forming technology, which is applied to flat products, household appliances, and other household appliances. It can solve the problems that the fire protection level of PMMA materials does not meet the fire protection requirements of buildings, and achieve the effect of narrow heat-softening temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

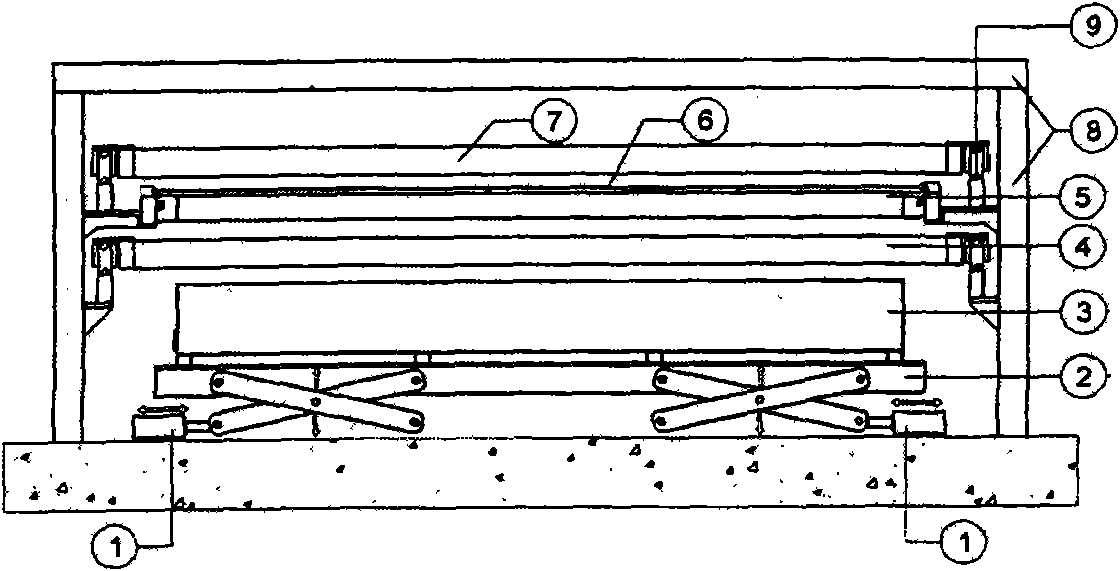

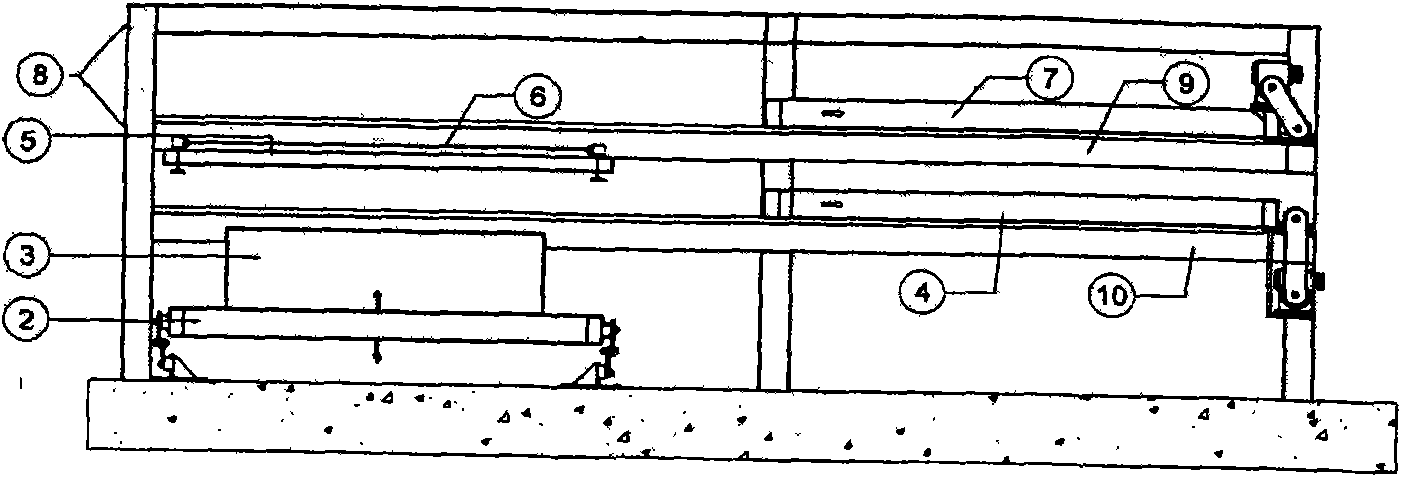

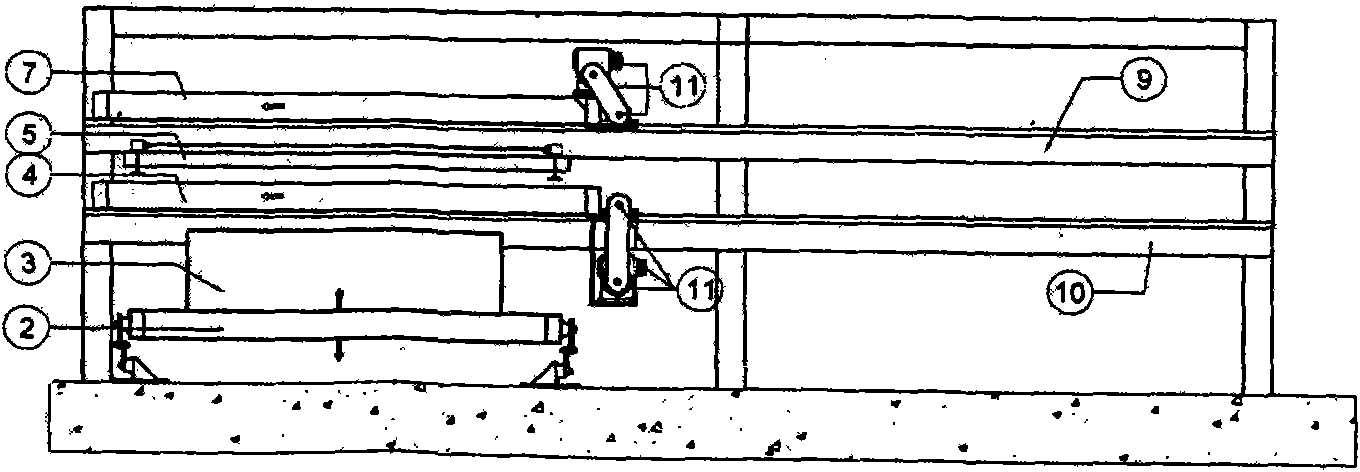

[0020] The present invention will be further described now in conjunction with accompanying drawing,

[0021] A method for forming large-scale plastic plates by suction, characterized in that:

[0022] Follow the steps below to implement:

[0023] 1) In the upper and lower plate heating devices where the flat plastic plate is located,

[0024] 2) The upper and lower plate heating devices preheat the plate plastic plate to 130-140°C, heat for 5-6 hours to remove moisture; make the water content of the plastic plate less than 0.02%,

[0025] 3) The upper and lower flat-plate heating devices heat the flat plastic sheet to 180-220°C for 5 minutes, and the plastic sheet becomes soft.

[0026] 4) Turn off the lower plate heating device and move out of the plastic plate area,

[0027] 5) The blister mold at the lower part immediately rises vertically to fit closely with the edge of the plastic sheet,

[0028] 6) The air extractor connected to the air extraction hole of the mold c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com