Fork lift with feeding mechanism

A technology for forklifts and hoisting mechanisms, applied in the direction of lifting devices, etc., to achieve the effect of convenient and easy disassembly, convenient and flexible operation, and improved working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

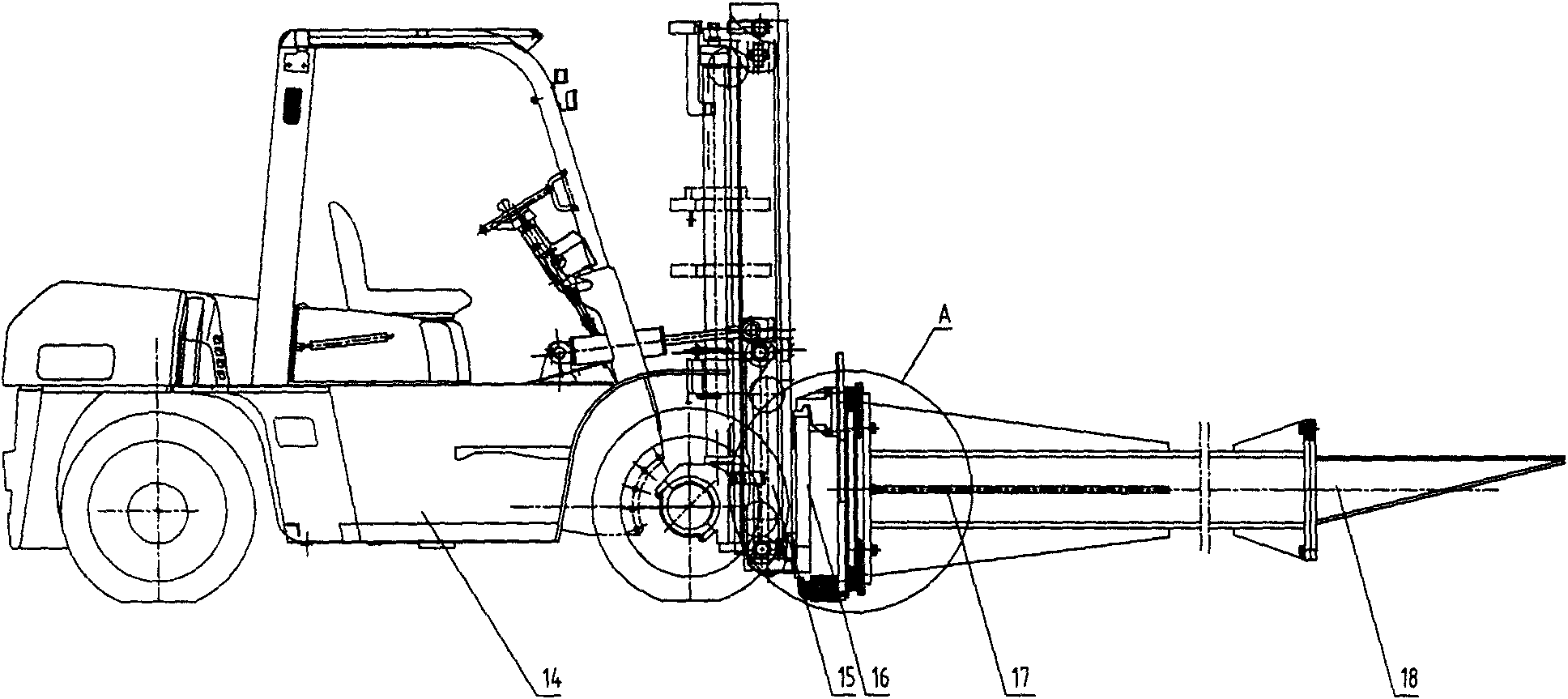

[0025] see figure 1 with figure 2 , the forklift with feeding mechanism comprises forklift truck body 14 and hoisting mechanism 15, and described hoisting mechanism 15 comprises pallet fork frame 16; and hopper 18.

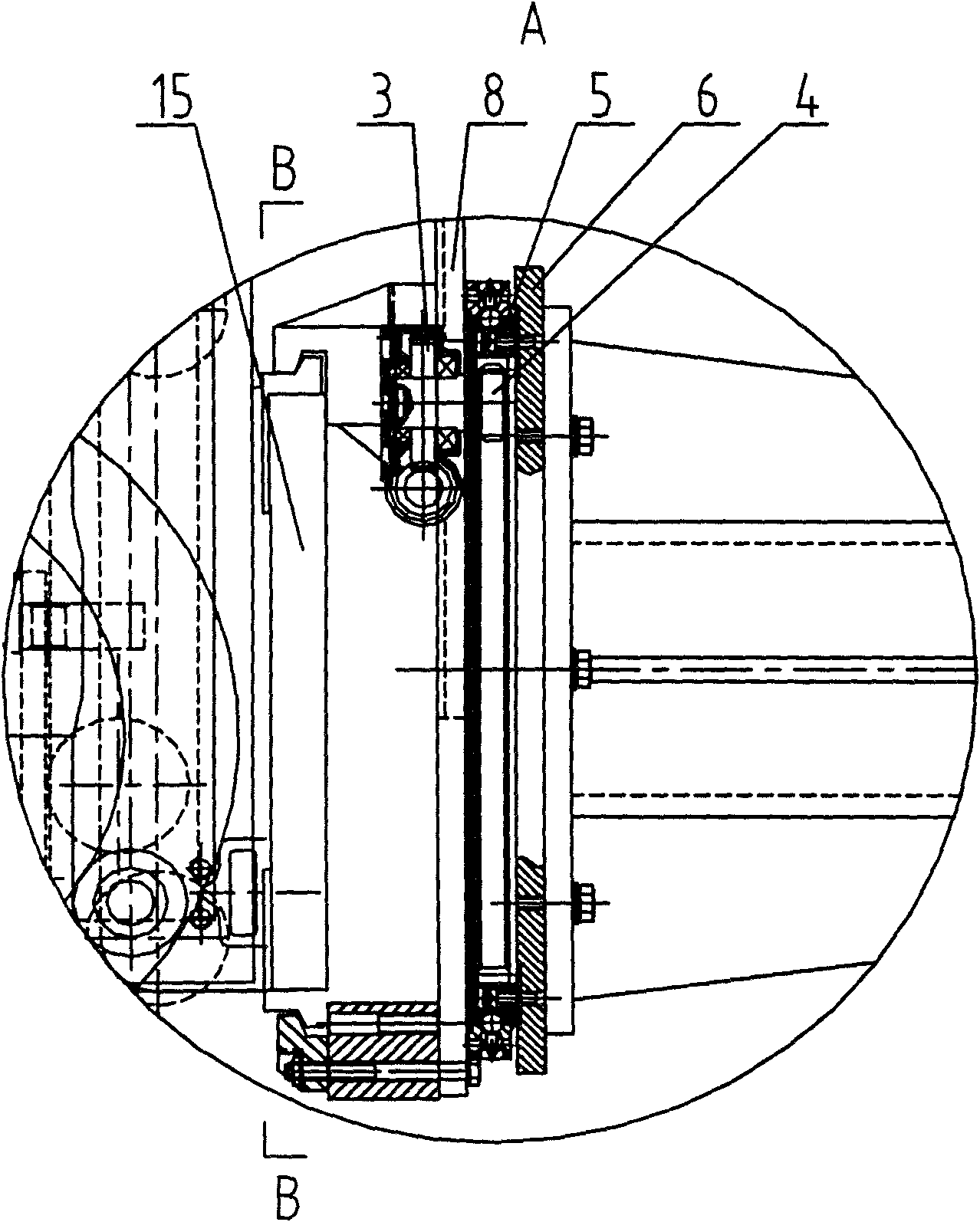

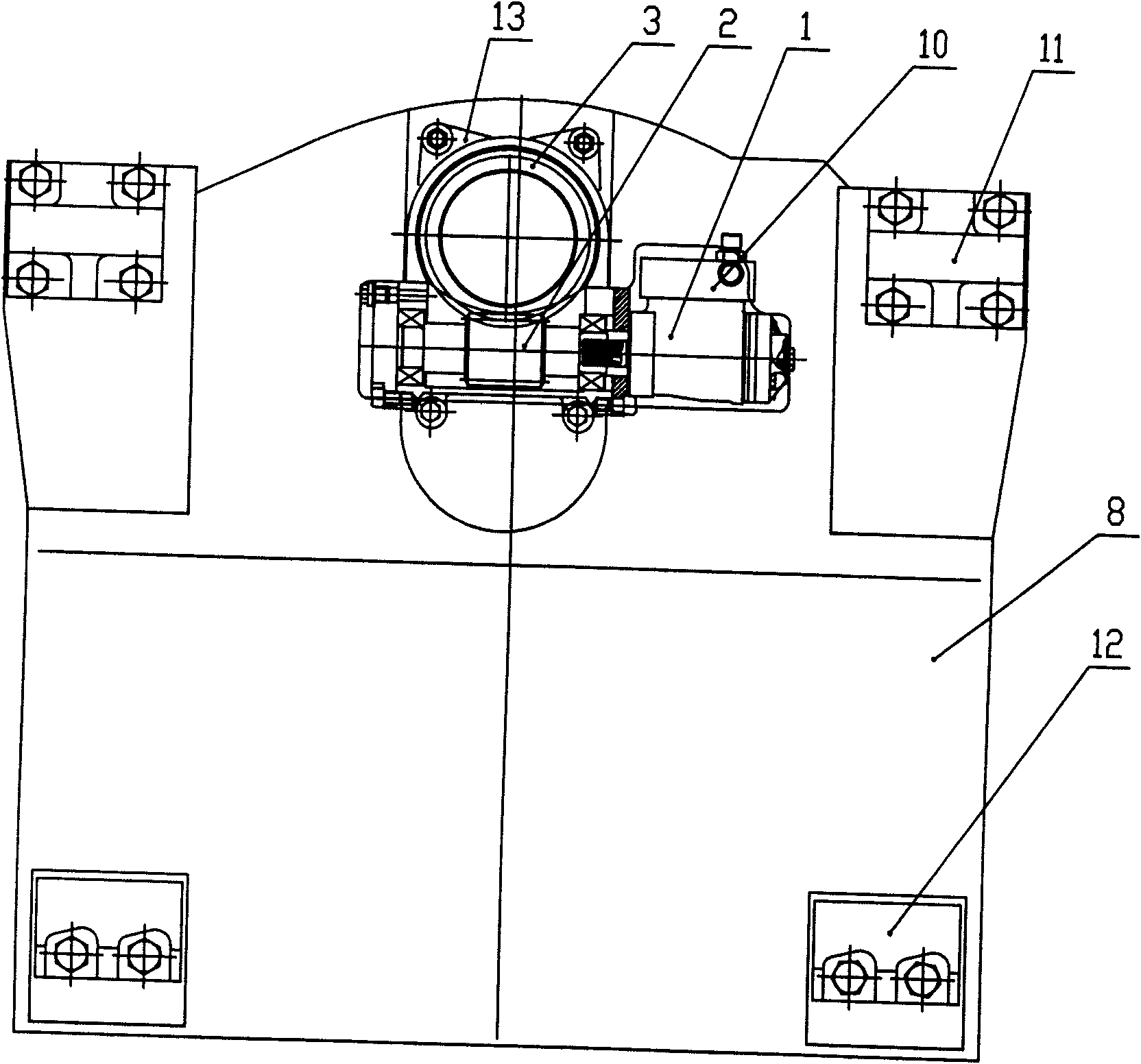

[0026] see image 3 with Figure 4 , The attachment rotating mechanism includes a front base plate 6, a rear base plate 8, a slewing mechanism and a speed reduction mechanism. The front bottom plate 6 and the rear bottom plate 8 are parallel to each other; the slewing mechanism includes a slewing bearing inner ring 5, a slewing bearing outer ring 7 and steel balls 9 between them; The circumferential surface is an inner gear ring; the outer ring of the slewing ring 7 is fixed and installed on the rear base plate 8 by bolts; steel balls 9 are evenly distributed between the inner ring 5 of the slewing ring and the outer ring 7 of the slewing ring, forming a slewing bearing;

[0027] The reduction mechanism includes a worm gear 3, a worm screw 2 and a hydraulic ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap