Hanger bracket loading test platform

A loading test and suspension technology, applied in the field of test benches, can solve the problems of low accuracy, no such test bench, complex structure, etc., and achieve the effects of convenient loading, convenient maintenance, and accurate load measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

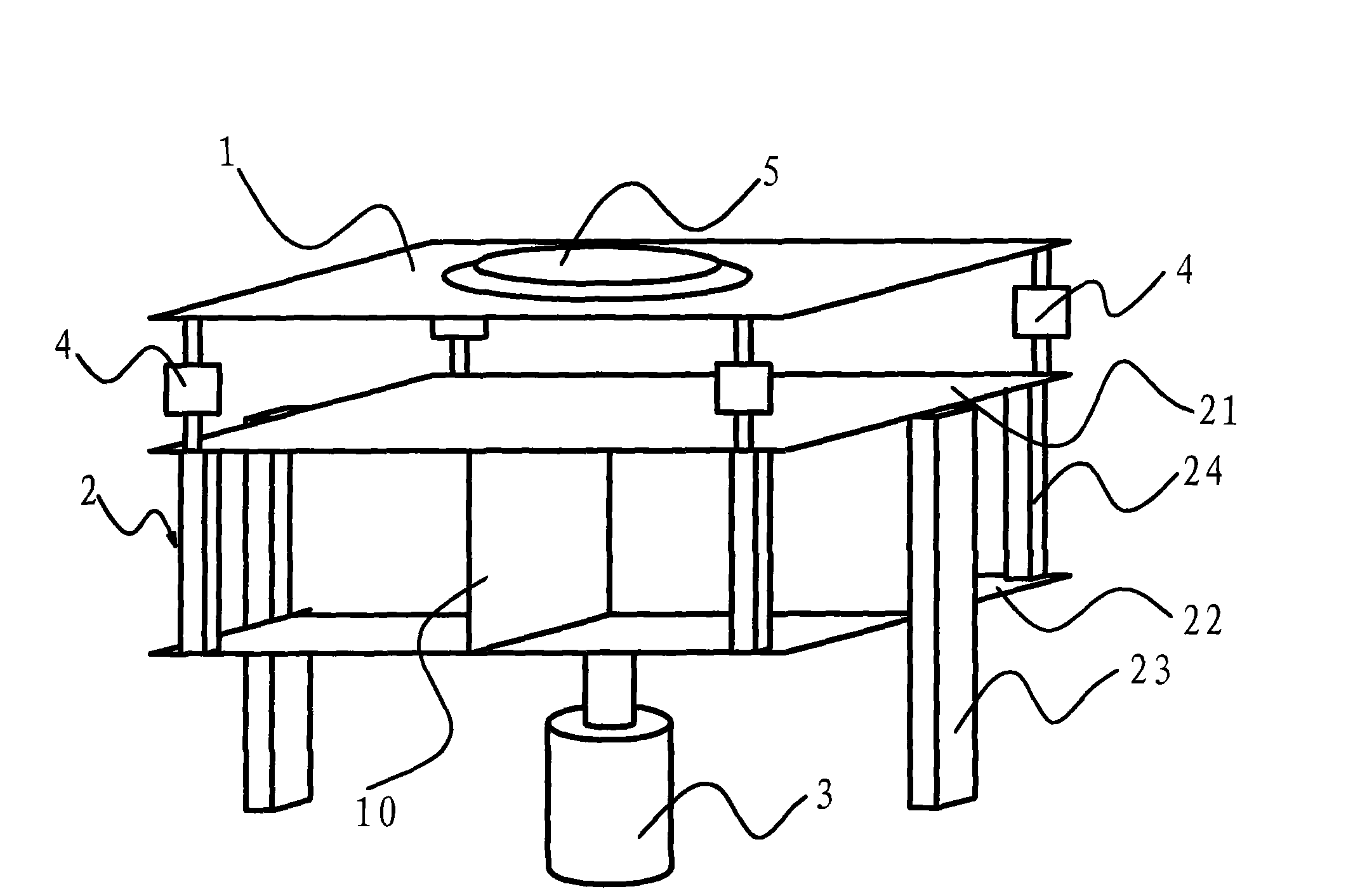

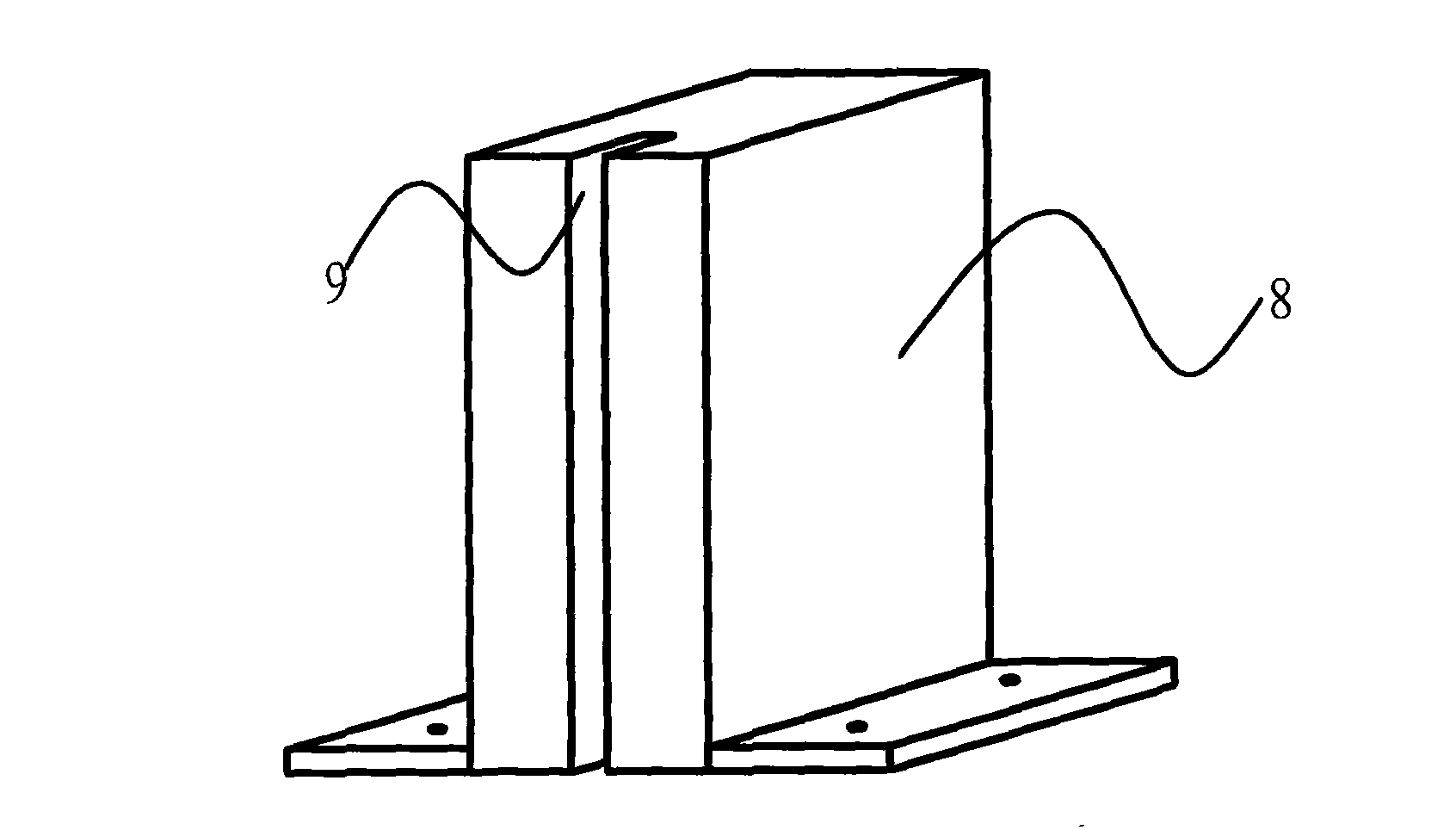

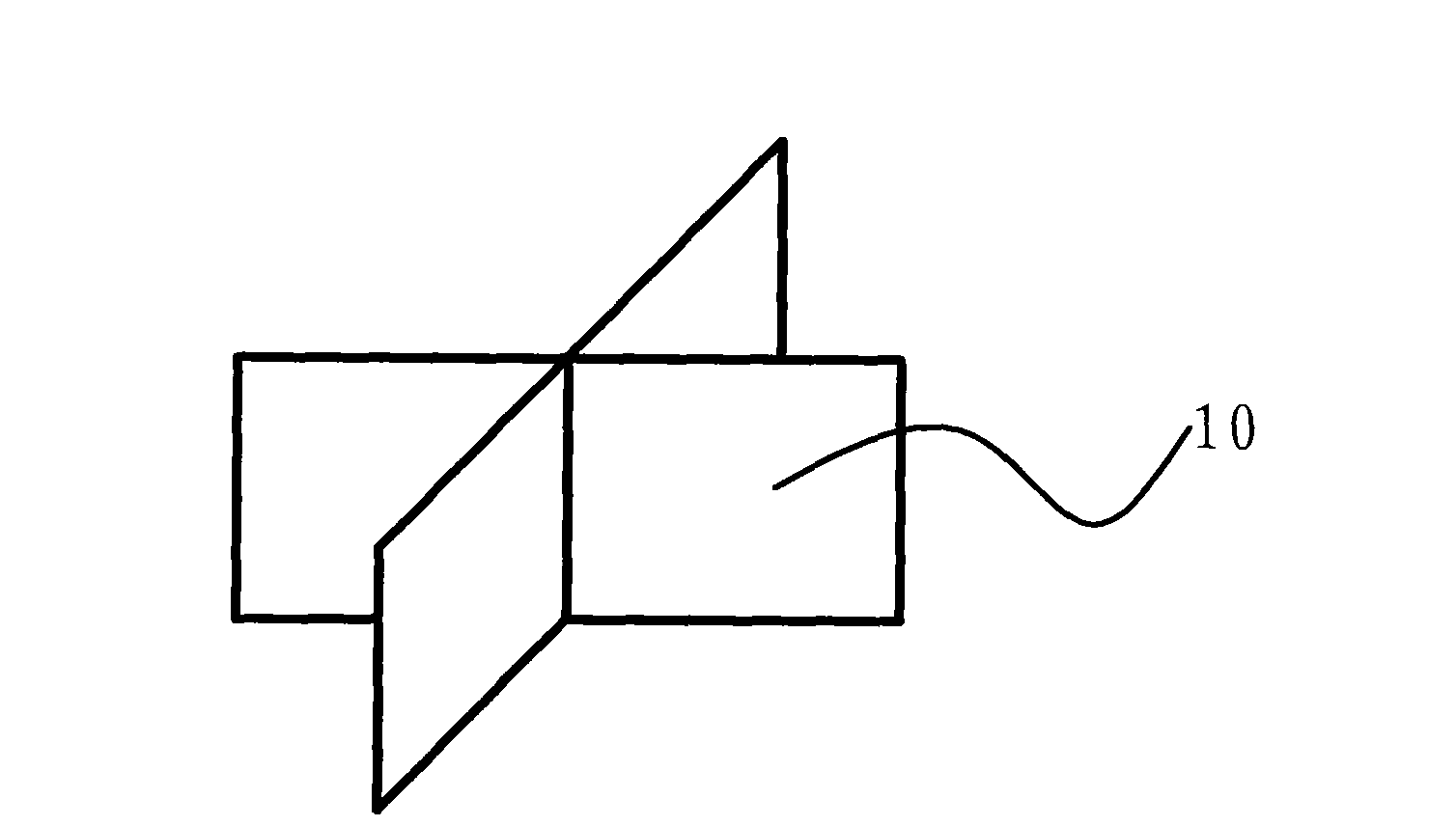

[0029] A kind of suspension loading test bench of the present invention, please refer to Figure 1 to Figure 5 The relevant figures in the middle include a weighing platform 1 and a load-bearing platform 2 located below the weighing platform 1. The weighing platform 1 is erected on the load-bearing platform 2. The function of the load-bearing platform 2 is to bear the suspension system and the weighing platform 1. and transmit the vertical upward loading force of the actuating element 3 located below it. The function of the weighing platform 1 is to carry the suspension system, and at the same time transmit the vertically loaded force of the suspension. The concrete load-bearing platform 2 includes an upper plate 21, a lower plate 22, and a support column 24 between the upper plate 21 and the lower plate 22. The function of the support column 24 is to support the upper plate 21, the upper plate 21 and the weighing platform 1 At least two load cells 4 are evenly arranged. The ...

specific Embodiment 2

[0030] A kind of suspension loading test bench of the present invention, please refer to Figure 1 to Figure 5 In the relevant figures, it is also possible to set a freely slidable slide plate 5 on the upper surface of the weighing platform 1 on the basis of the specific embodiment one. The slide plate 5 is an upper and lower layer structure, and the lower layer of the slide plate 5 is fixed on the weighing platform 7. , Balls are provided between the lower floor and the upper floor of the slide plate 5, the upper floor slides freely on the balls, and the upper floor and the lower edge can be connected by elastic bands. The slide plate 5 is provided with a horizontal plane, and the suspension system is arranged on the horizontal plane of the slide plate 5. Since the slide plate 5 is arranged on the weighing platform 1, the setting of the slide plate 5 makes it possible to carry out other small machines or components of the suspension system. Weighing and loading load calibrati...

specific Embodiment 3

[0031] A kind of suspension loading test bench of the present invention, please refer to Figure 1 to Figure 5 In the relevant figures, on the basis of the specific embodiment 1 and the specific embodiment 2, four load cells 4 can be evenly arranged between the upper plate 21 and the weighing platform 1, and four load cells 4 can be set. The advantage of the sensor 4 is that the measurement is more accurate in this way, and the accuracy of the calibration is improved. A further preferred solution is to set a load cell 4 between the upper plate 21 and the weighing platform 1 at each of the four corners of the upper plate 21, thus ensuring that the four load cells 4 are The uniform setting also ensures the stability of the suspension system on the weighing platform 1, further improving the accuracy of measurement and calibration. Further, the weighing platform 1 and each of the load cells 4 are connected by bolts. The advantage of such a connection method is that the paralleli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com