A bearing fault prediction test system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The technical scheme of the present invention is described in detail below in conjunction with the accompanying drawings, in order to facilitate a comprehensive understanding.

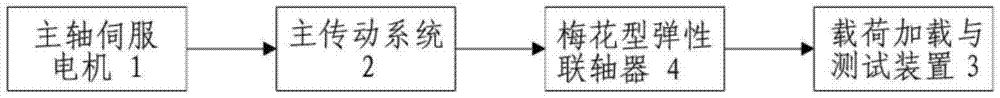

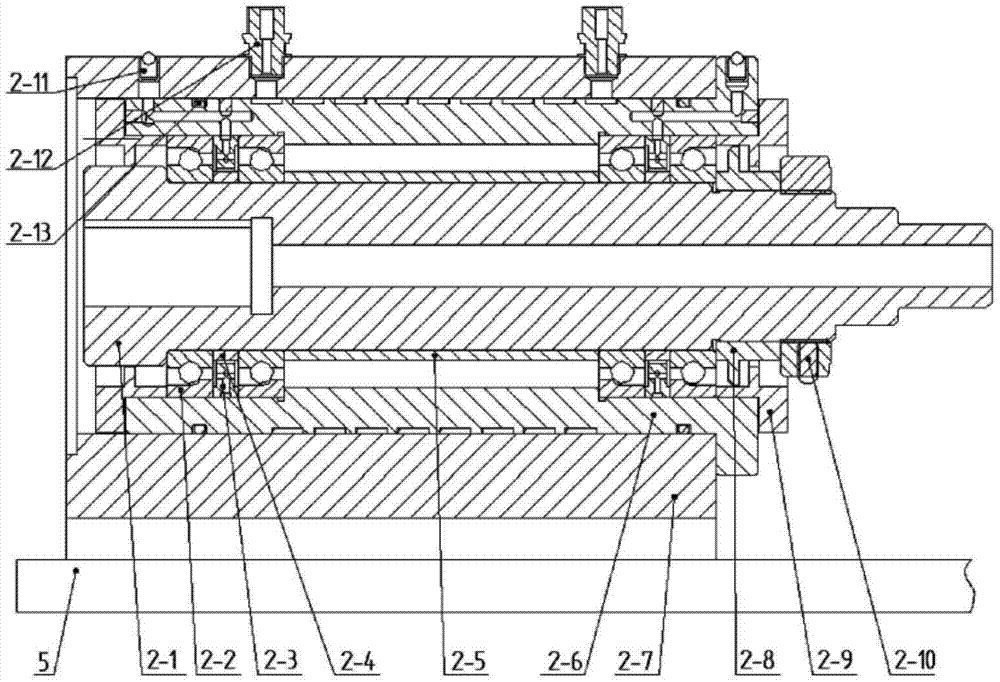

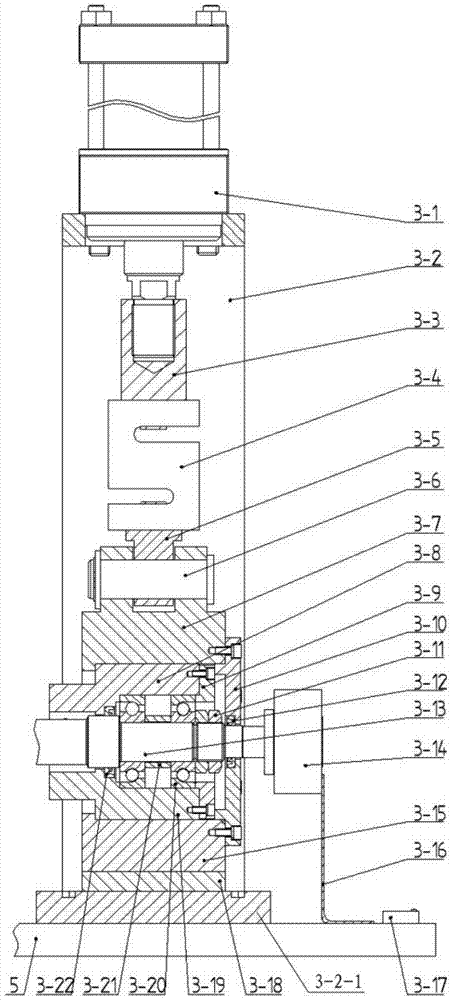

[0083] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a bearing failure prediction test system includes a base 5, a main shaft servo motor 1, a main transmission system 2, a plum-shaped elastic coupling 4 and a load loading and testing device 3; figure 1 ;

[0084] The main shaft servo motor 1 and the main transmission system 2 are fixedly installed on the base 5; the main shaft servo motor 1 is driven by a servo driver, and the main shaft servo motor 1 is connected to the main transmission system 2 through a connecting key;

[0085] The main transmission system 2 and the load loading and testing device 3 are connected through the quincunx elastic coupling 4, and the three have independent lubrication systems respectively.

[0086] The main drive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com