Laser material level meter loading mechanism of high-pressure slag skimming and loading machine for smelting magnesium metal

A charging mechanism and material level gauge technology, which is applied in the field of laser material level gauge charging mechanism, achieves the effects of stable and reliable performance, simple device structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

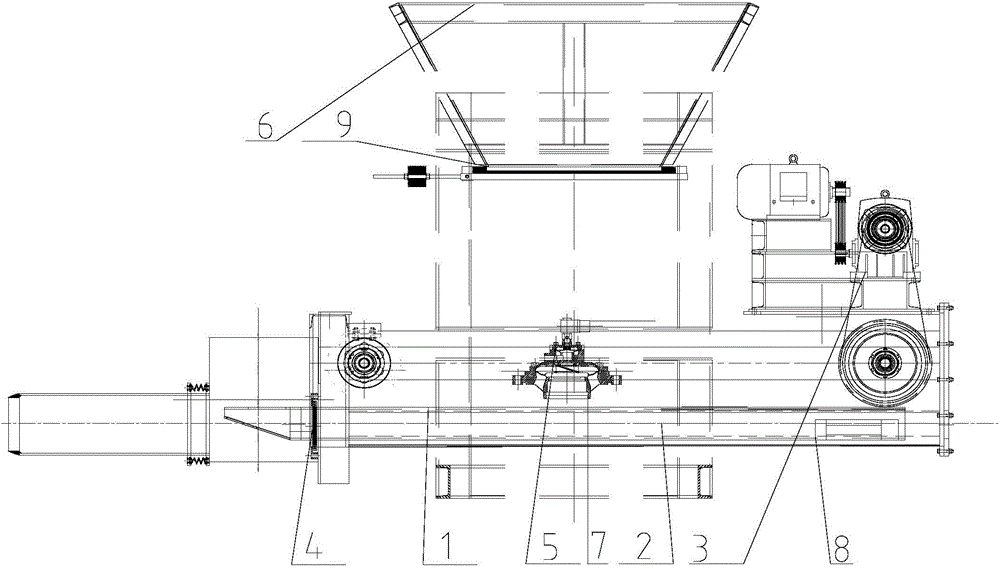

[0011] Embodiment 1: A kind of metal magnesium smelting high-pressure slag removal surface charging machine Laser level gauge charging mechanism work process: The charging pipe 1 of the charging mechanism makes a linear reciprocating motion under the traction of the slag-removing charging pipe traction mechanism 3, and the high-pressure compressed air flow enters the charging pipe 1 through the action of the pulse valve 7, and the material dropped from the charging box 6 It forms a plug and sends it into the reduction tank. The material falling in the charging box 6 is controlled by the laser level gauge 8, and the charging box pneumatic flapper valve 9 opens or closes the bottom of the charging box 6 according to the indication signal of the laser level gauge 8. In order to ensure the airtightness between the air guide pipe 2 and the charging pipe 1, an air guide pipe and a slag removal pipe sealing seat 4 are arranged between the two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com