Laser charge level indicator charging mechanism of metal magnesium smelting high-pressure charger of 290mm-diameter reduction pot

The technology of a charging mechanism and a material level gauge is applied in the field of laser material level gauge charging mechanism to achieve the effects of simple device structure, high degree of automation, stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Example 1: A laser level meter charging mechanism of a high-pressure slag-removing charging machine for metal magnesium smelting with a reduction tank with a diameter of 290mm work process:

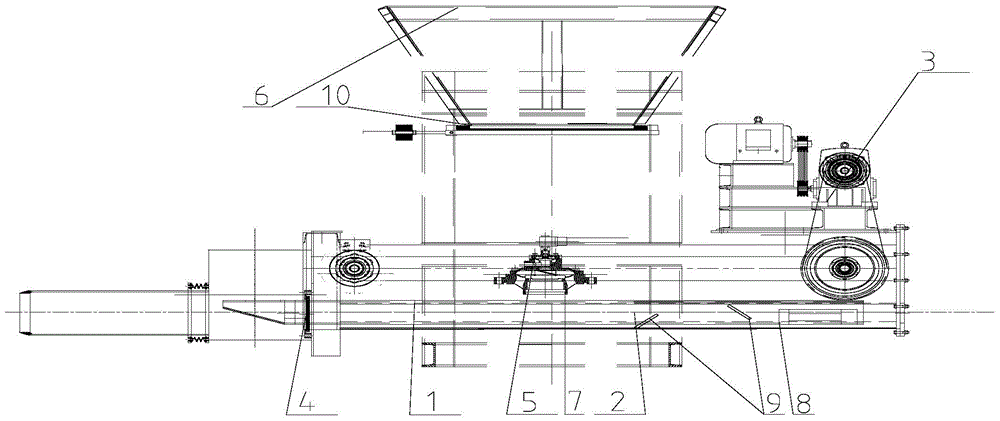

[0012] The invention relates to a laser level meter charging mechanism of a high-pressure slag-slagging charging machine for metal magnesium smelting with a diameter of 290 mm. 3. Air duct and charging pipe sealing seat 4. Pulse valve intake pipe 5. Charging box 6. Pulse valve 7. Laser level gauge 8. Laser level gauge reflector 9. Pneumatic slide valve for charging box 10 The composition is characterized in that the charging pipe 1 of the charging mechanism of a high-pressure slag-removing and charging integrated machine for metal magnesium smelting is linearly reciprocating under the traction of the slag-removing and charging pipe traction mechanism 4 . The air guiding pipe and the sealing seat 4 of the charging pipe are a group of front and rear sealing seats. There are seve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com