Inorganic film etching method in semiconductor manufacture procedure and shallow groove isolation area forming method

A shallow trench isolation region, inorganic film technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as poor operability, and achieve the effect of enhancing consistency and reducing the possibility of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

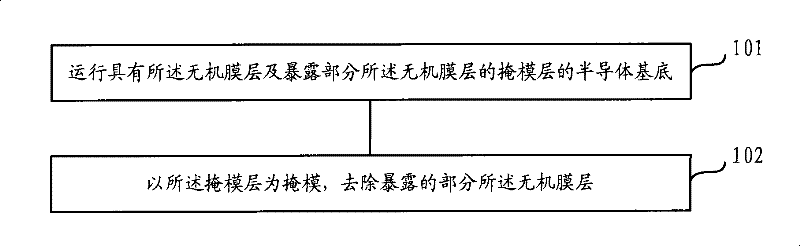

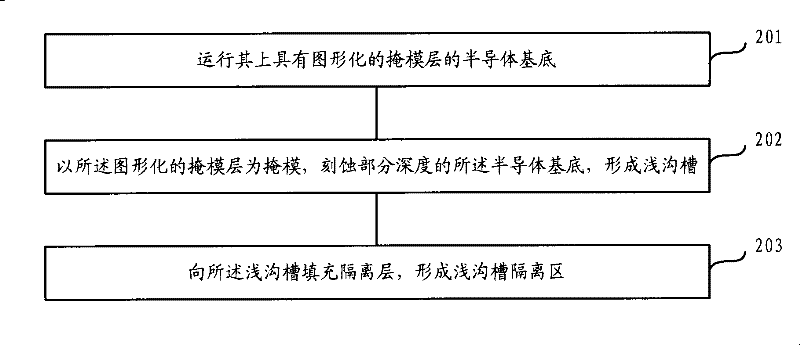

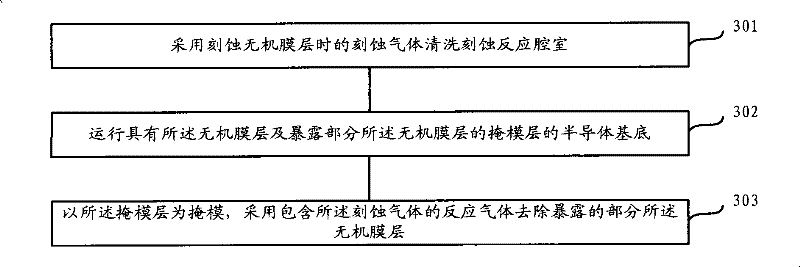

Method used

Image

Examples

no. 1 example

[0044] As a first embodiment of the present invention, the inorganic film layer includes a polysilicon layer; the operation of etching the inorganic film layer may be an operation of etching the polysilicon gate layer to form a polysilicon gate layer after forming the polysilicon gate layer .

[0045] When the inorganic film layer includes a polysilicon layer, the etching gas includes SiCl 4 , the SiCl 4 The flow range is 10-300sccm, such as 30sccm, 90sccm, 120sccm, 150sccm; when performing the cleaning operation, the reaction power is 500-2000W, such as 1000W, 1250W, 1500W; when performing the cleaning operation, the reaction pressure is 10-2000W 100mT, such as 50mT, 65mT, 80mT; when performing the cleaning operation, the duration of the pre-cleaning operation is 5-20 seconds, such as 10 seconds, 12 seconds, 15 seconds.

[0046] As a second embodiment of the present invention, the inorganic film layer includes a dielectric layer; the dielectric layer includes an oxide layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com