Device for preparing membrane by liquid level sedimentation method

A technology of sedimentation method and liquid level, which is applied to the device and coating of the surface coating liquid, which can solve the problems of difficult control of film thickness, difficulty of industrial application, difficulty of curing atmosphere, etc., to achieve convenient preparation and controllable thickness , the effect of reducing the amount of liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

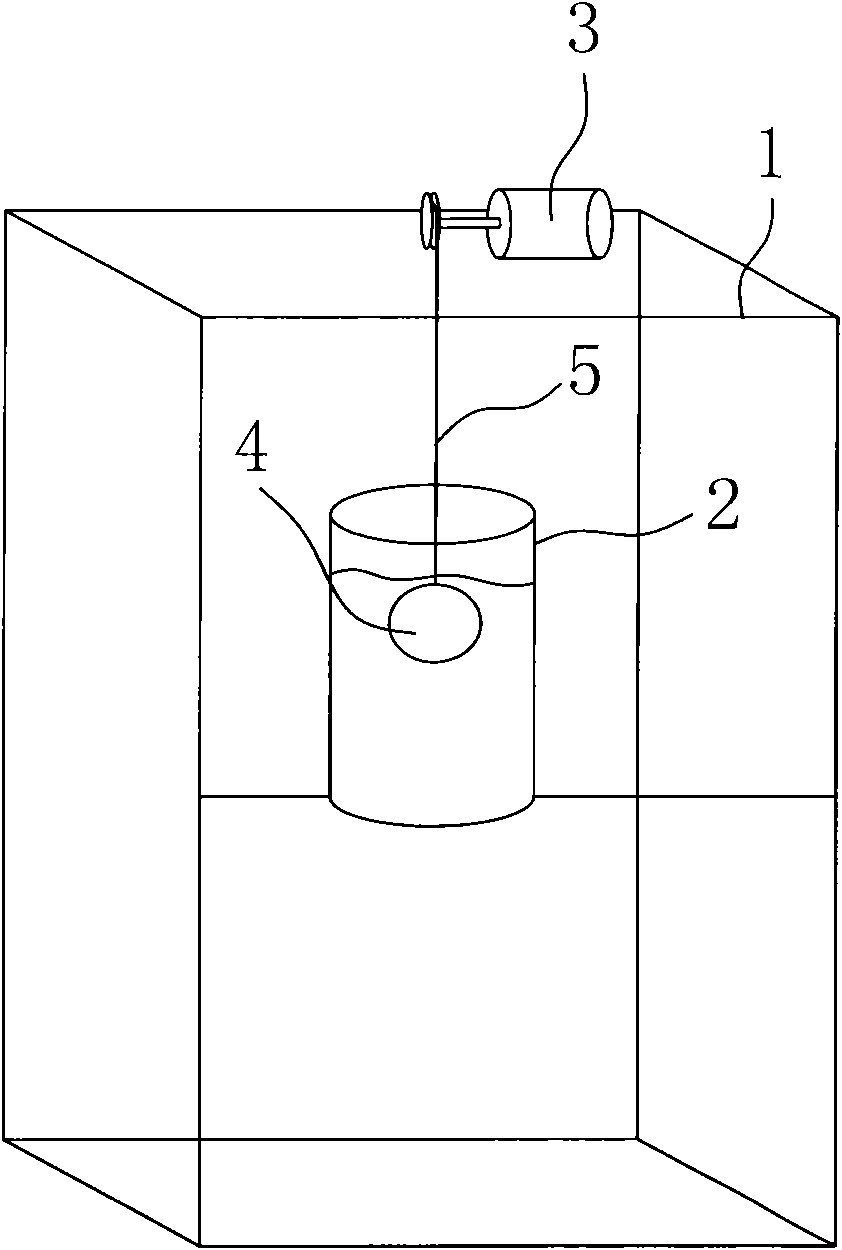

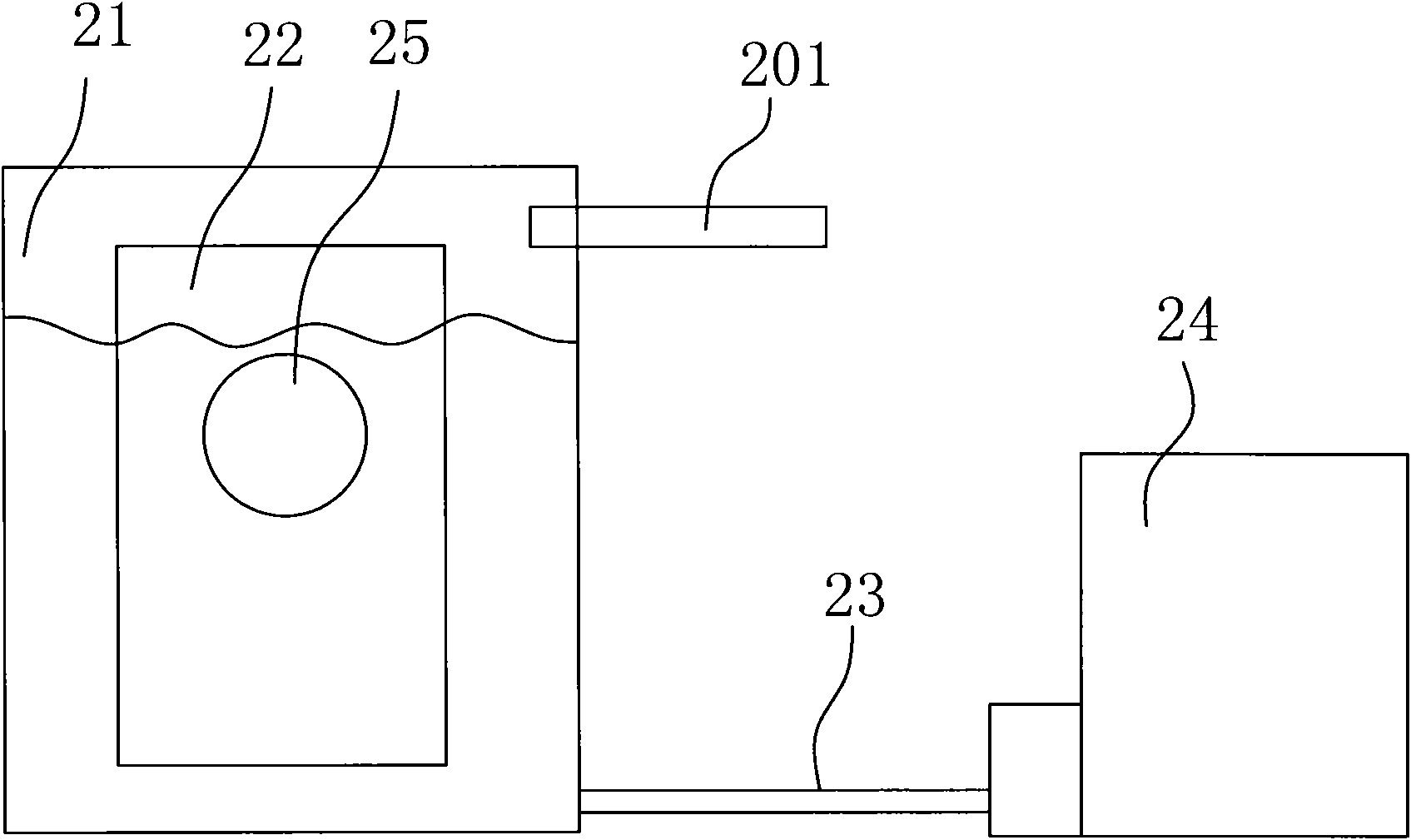

[0029] Such as figure 2 , 3 As shown, this embodiment provides a device for preparing a thin film by a liquid level sedimentation method, which is used to prepare a thin film on a substrate. The device specifically includes:

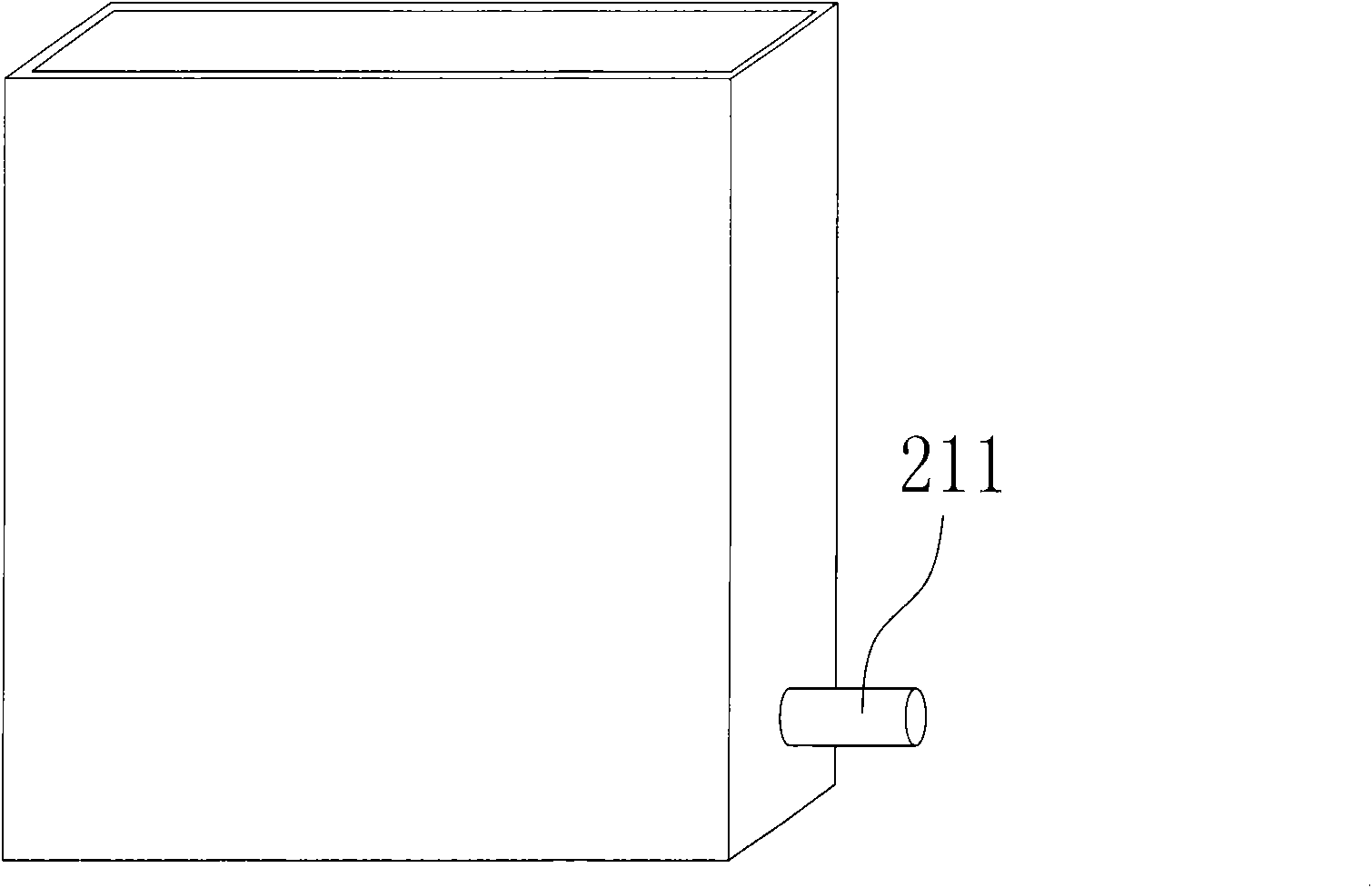

[0030] Container 21, heating plate 22, liquid reservoir 24 and pipeline 23, wherein, described container 21 is a square flat structure, is provided with infusion port 211 on the container, and described container 21 passes through infusion port 211 through pipeline 23 and liquid reservoir 24 communicates; the container 21 is provided with a heating plate 22 (controllable heating plate can be used), and the heating plate 22 is corresponding to the position of the substrate 25 for film formation in the container 21, and is used for drying and annealing of the film. Among them, the container 21 with a square flat structure can effectively reduce the amount of liquid used when preparing the thin film. Only a small amount of liquid can be used to soak the s...

Embodiment 2

[0035] Such as Figure 5 As shown, this embodiment provides a device for preparing thin films by liquid level settling method with adjustable inclination angle. Specifically, on the basis of the device described in Embodiment 1, a container inclination adjuster 28 is provided, and the inclination angle of the container is adjusted The device 28 is a fan-shaped flat plate structure, and a plurality of positioning clips 27 and a movable card seat 26 for placing the container are evenly arranged on one side of the container inclination adjuster 28, and the container 21 for placing the substrate is placed on the container inclination adjustment On the movable holder 26 of the device 28, the upper end of the container 21 is clamped on the positioning clamp 27 of the container tilt adjuster 28. When the upper end of the container 21 is clamped on the positioning clamp 27 at different positions, the container 21 is then positioned At different inclination angles, because it communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com