Grinding mat provided with groove structure for preventing grinding surface from falling off

A technology for grinding pads and grinding surfaces, which is applied in the field of grinding pads, can solve the problems of reducing grinding quality and grinding effect, and achieve the effects of increasing grinding effect, good grinding quality, and facilitating elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

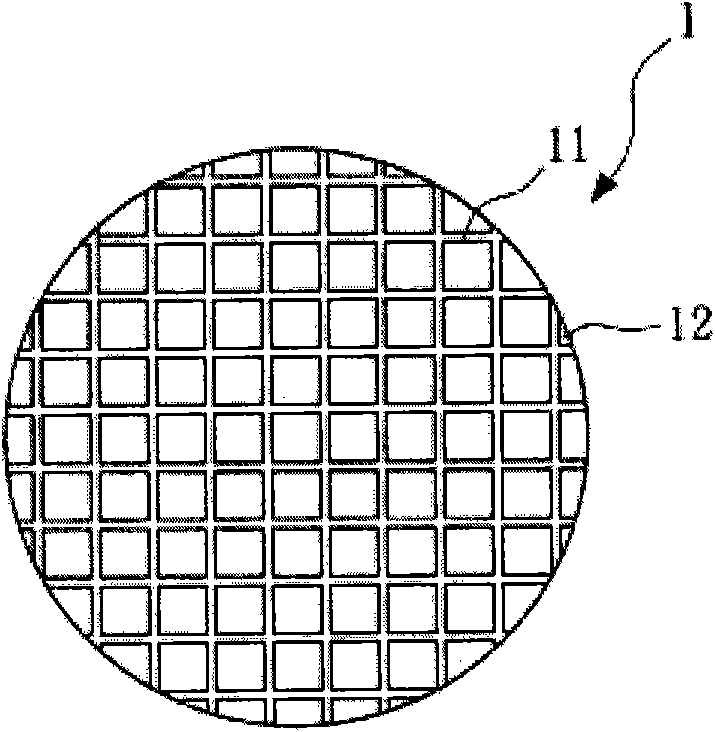

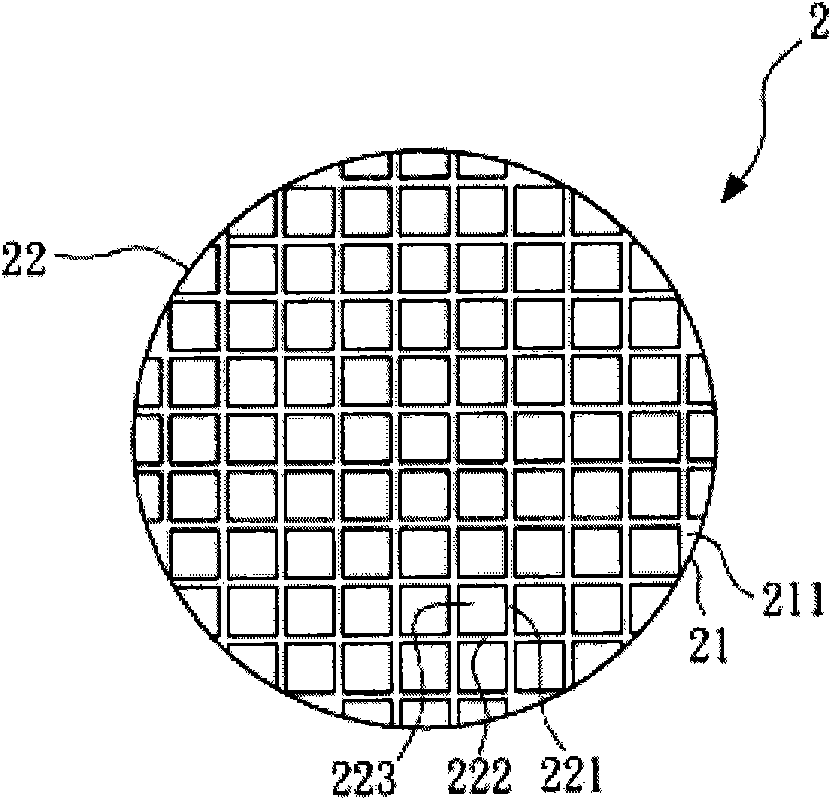

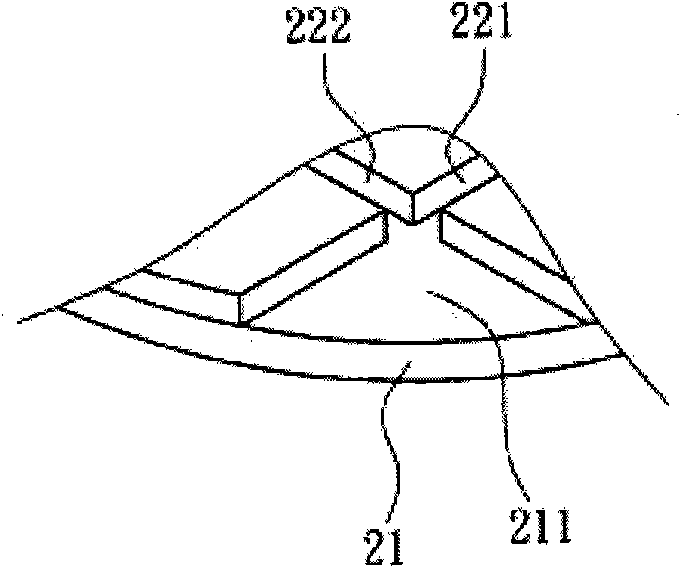

[0012] Figure 2A A schematic diagram showing a polishing pad having a groove structure for preventing the polishing surface from falling off according to the first embodiment of the present invention; Figure 2B A schematic partial perspective view of the polishing pad with the groove structure for preventing the polishing surface from falling off according to the first embodiment of the present invention is shown. with reference Figure 2A and Figure 2B , the polishing pad 2 includes: a substrate 21 and a polishing layer 22 . The substrate 21 has a surface 211 . The grinding layer 22 is disposed on the surface 211 and exposes a portion of the surface 211 around the substrate 21 . The grinding layer 22 has a plurality of first grooves 221 and a plurality of second grooves 222 , the first grooves 221 intersect with the second grooves 222 to define a plurality of grinding regions 223 . The exposed part of the surface 211 of the periphery of the substrate 21 is located bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com