Non-contact screen printing method and non-contact screen printing equipment

A technology without catenary and printing equipment, applied to screen printing machines, printing, printing machines, etc., can solve problems such as loss, less printing ink, and rupture of printed matter 70a, so as to achieve rapid adjustment, improve printing stability, and increase The effect of printing uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the present invention more definite and detailed, the preferred embodiments are listed hereby in conjunction with the following diagrams, and the structure and technical characteristics of the present invention are described in detail as follows:

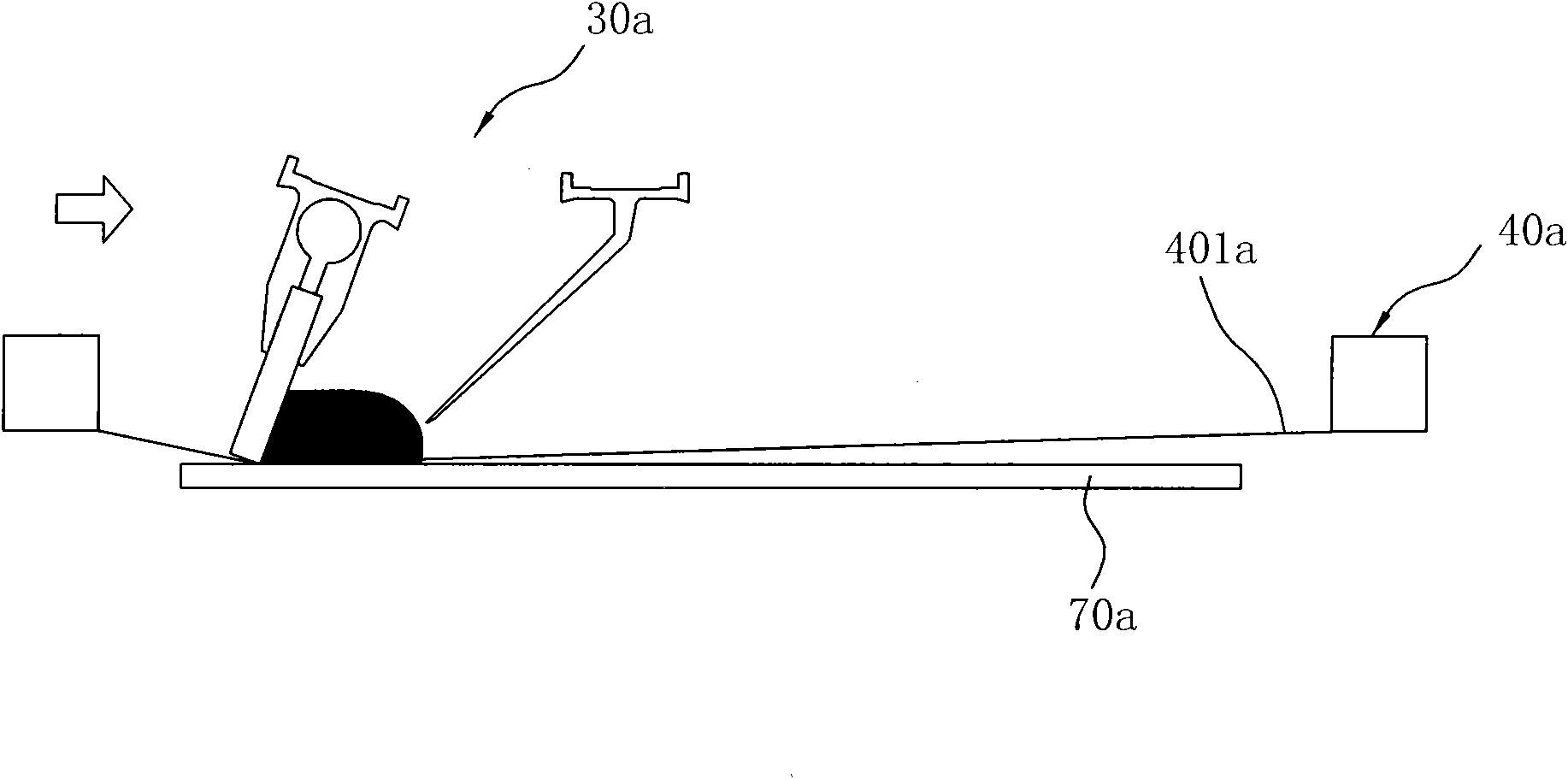

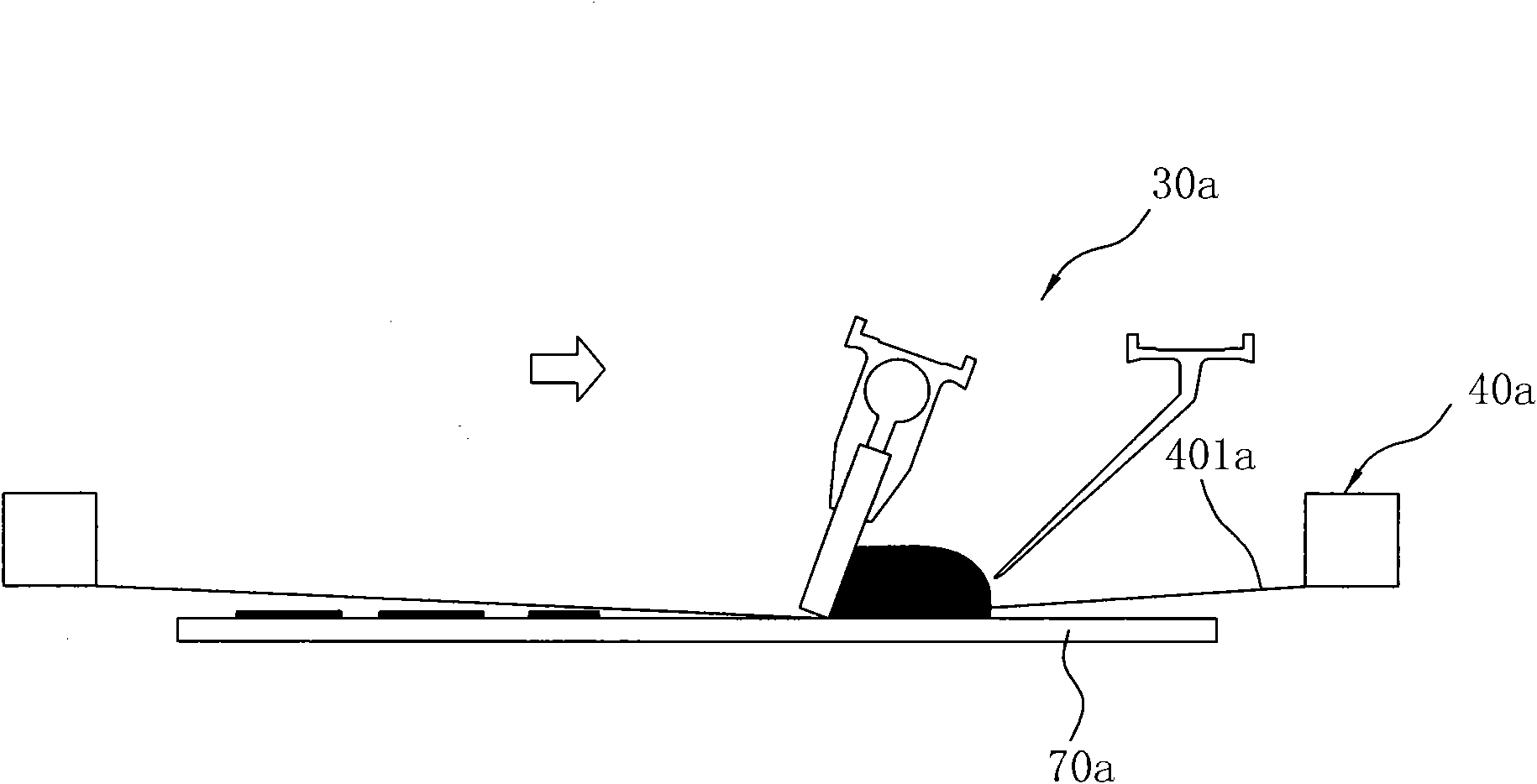

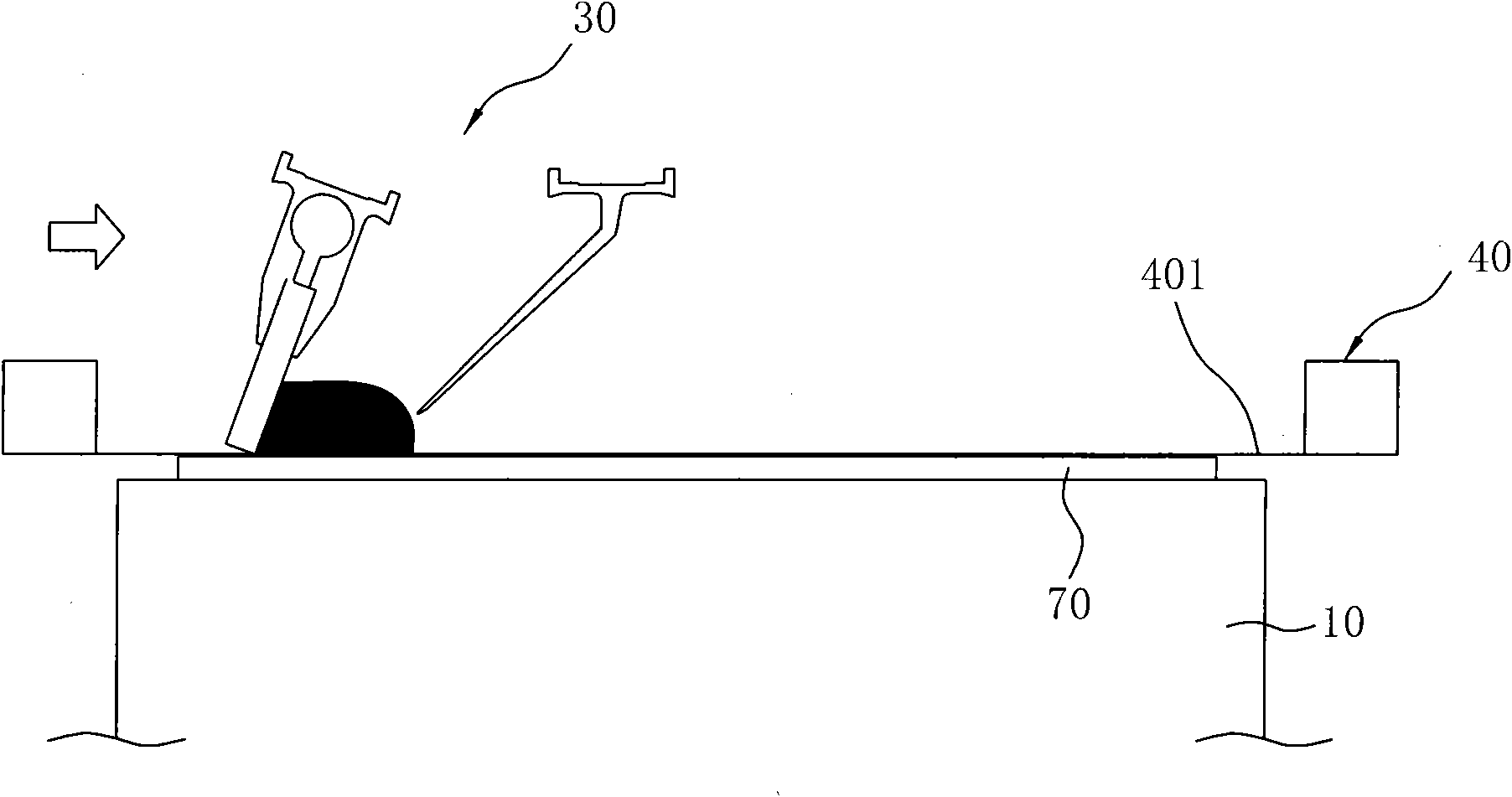

[0042] Please refer to image 3 as well as Figure 4 As shown, the non-contact screen printing method of the present invention, wherein the non-contact screen printing method relies on controlling the distance between the screen plate 40 and the printed matter 70 on the printing table 10, using a constant scraping pressure to make the The screen 40 is not in contact with the printed matter 70 , and the printing ink is scraped and printed on the surface of the printed matter 70 through the mesh cloth 401 of the screen 40 by means of the printing scraper 30 .

[0043] Please refer to Figure 5-8 As shown, a non-contact screen printing device of the present invention includes: a printing table 10, a printing h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com