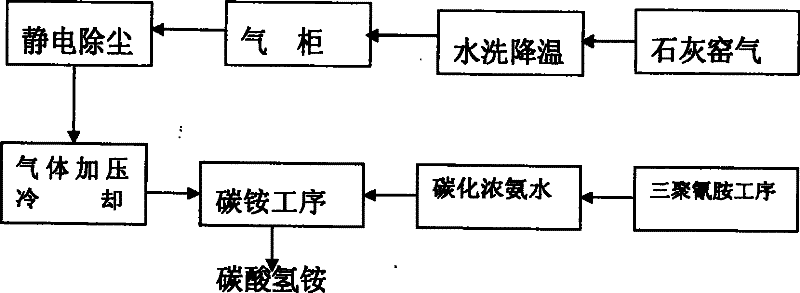

Process of jointly producing melamine and ammonium bicarbonate with limekiln gas

A technology of ammonium bicarbonate and melamine, applied in the chemical industry, can solve the problems of carbon dioxide deficiency and ammonia excess, and achieve the effect of increasing enterprise income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In the case that the melamine production line is matched with the continuous calcining lime kiln, the tail gas of the lime kiln is drawn out by a fan, and the oxygen content in the tail gas is controlled to be 0.8%, the carbon dioxide is 30%, the pressure is 480mm water column, and the temperature is 100°C. The gas washed and cooled to 35°C is sent to the gas cabinet, and the gas in the gas cabinet is drawn out by the Roots blower and then subjected to electrostatic dust removal, then pressurized and cooled by the compressor, and then the pressure is controlled at 0.9Mpa and the temperature is 35°C. , react with concentrated ammonia water in the carbonization tower to form ammonium bicarbonate crystals, and the crystal liquid is separated by a thickener and a centrifuge to obtain ammonium bicarbonate products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com