Jet pressing burning splitting ring curled turbine engine

A turbine engine, toroidal technology, applied to engine components, gas turbine devices, machines/engines, etc., can solve the problems of low power and turbine blade strength and life, unfavorable engine high-speed airflow dynamics, and limited temperature and pressure tolerance. Reach the effect of index and cost reduction, simple manufacturing process and reduction of aerodynamic resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

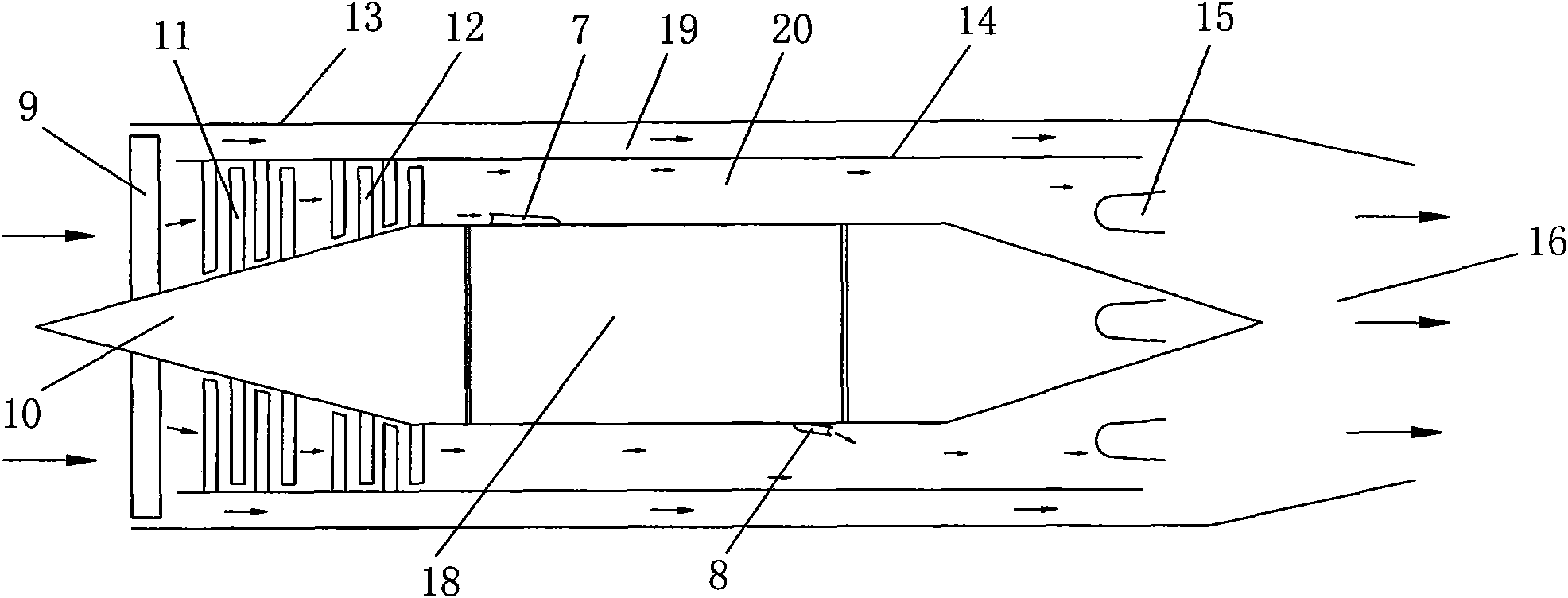

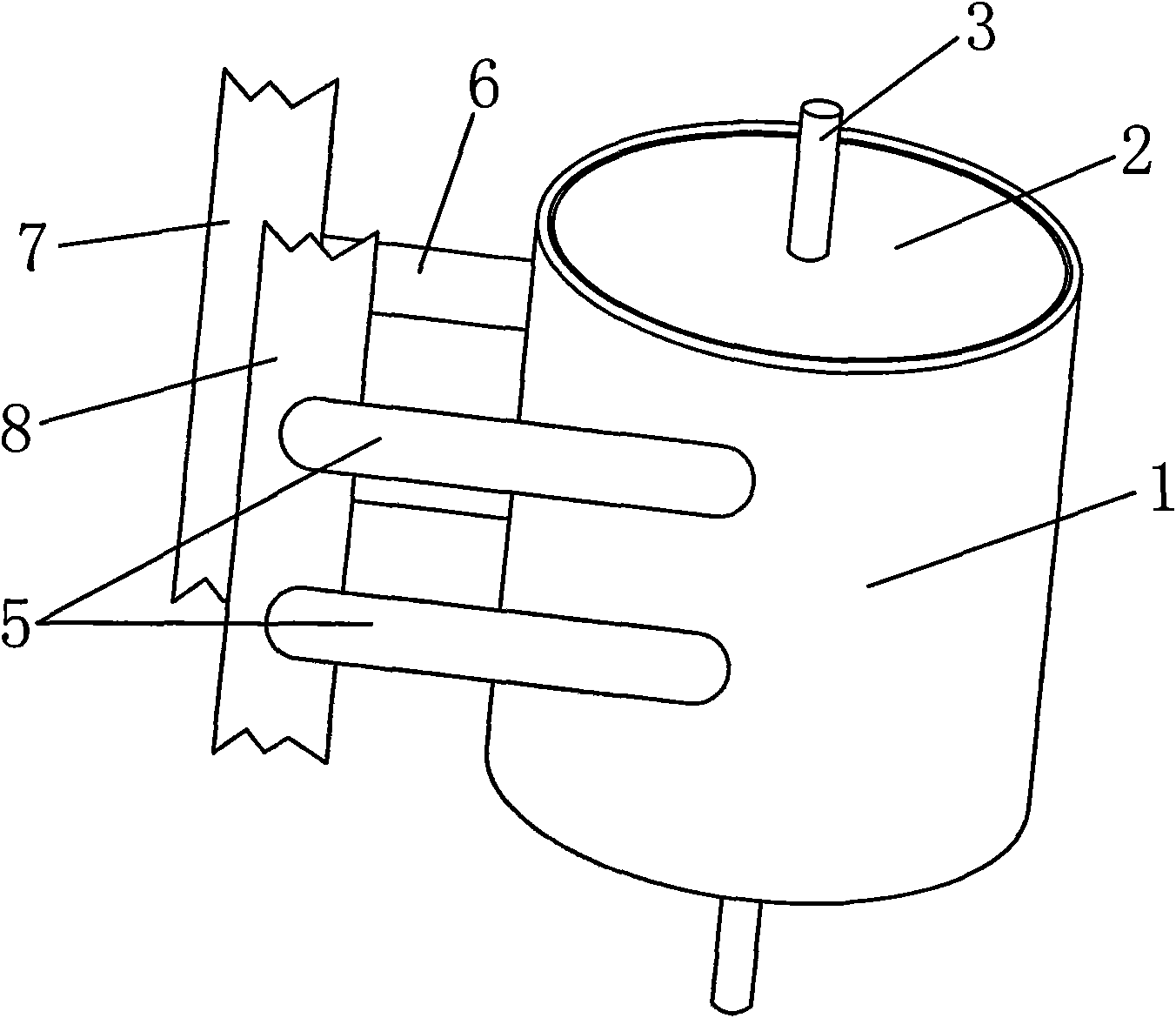

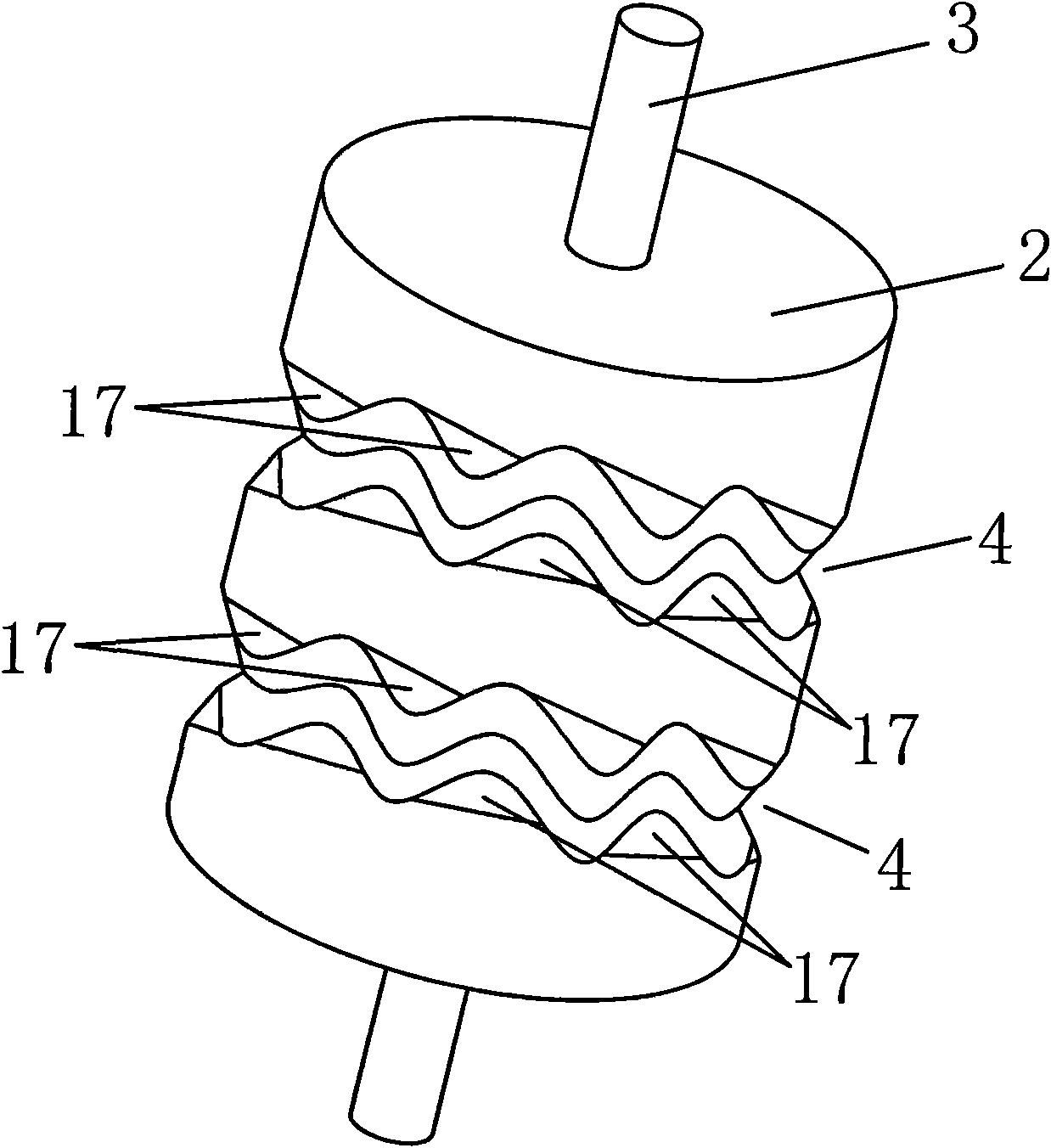

[0019] see figure 1 , this kind of pressure-injection-divided combustion type toroidal curved turbine engine includes an outer casing 13, an inner casing 14, a fan 9, a low-pressure compressor 11, a high-pressure compressor 12, a turbine 18, a combustion chamber 15 and a tail nozzle 16, and the low-pressure compressor 11. The high-pressure compressor 12 and the turbine 18 are arranged coaxially in the inner casing 14 in turn, the inner casing 14 is fixedly arranged in the outer casing 13, and the fan 9 is arranged at the front air intake end of the outer casing 13 and connected with the low-pressure compressor. 11 are coaxial, and the fan 9 is also provided with a fairing 10. Combustion chamber 15 is located at the inner shell 14 afterbody of turbine 18 rear, and the jet outlet rear of combustion chamber 15 is tail nozzle 16; Total air outlet pipe 8, total air intake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com