Cuvette and preparation method

A cuvettes and hollow technology, which is applied to the cuvettes with constant temperature function and the field of preparation, can solve the problems of adding heating devices, affecting the test results, complexity, etc., to achieve the effect of uniform temperature and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

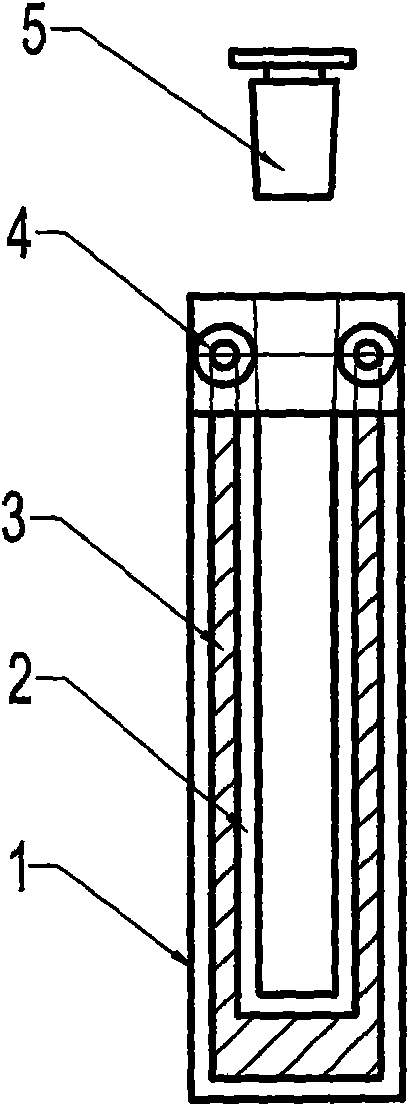

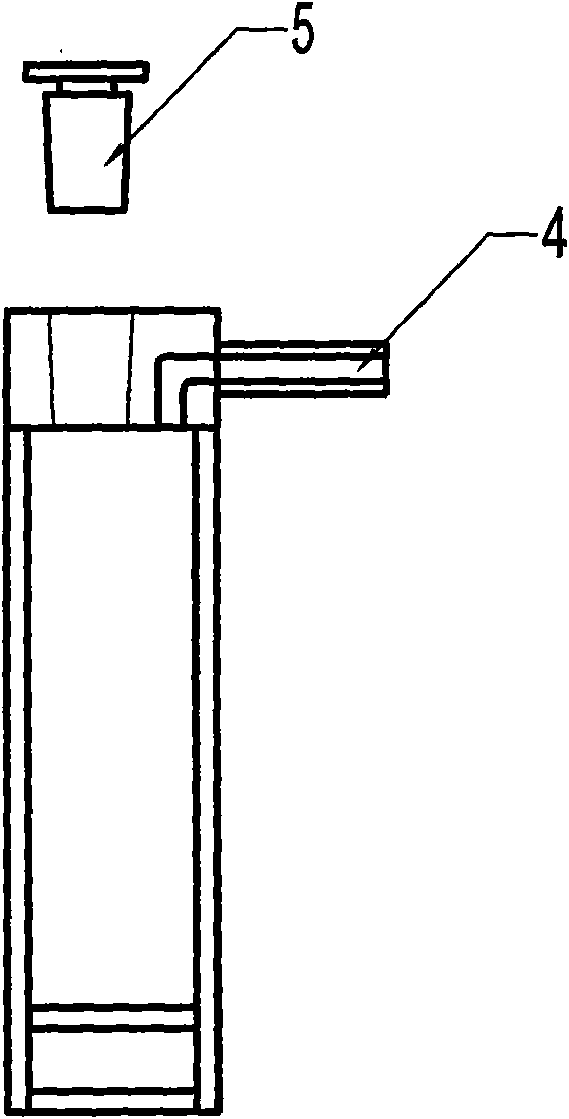

[0023] Embodiment: Referring to the accompanying drawings, the glass cuvette of the present invention (structure is a rectangular cross-section), the optical processing two plane widths are substantially equal quartz glass optical strips, respectively heating and bending to make 2 U-shaped 1 and 2 with different bending widths , put two curved U-shaped glass slides in the air, and temporarily fix them on the surface of the glass substrate with a rosin-asphalt mixed adhesive. Grind and process the U-shaped adhesive to position the opposite side to be equal, and bond (permanently bonded) Knot) light-transmitting flat sheet, separated from the positioning substrate, grinding and processing the original bonded side to the optical path size, bonding (permanently bonding) another light-transmitting flat sheet, processing the top surface to the same height, and bonding a short tube The sealing plate of the mouthpiece 4 is bonded (permanently bonded) to the top of the interlayer openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com