Method and device for compensating for a transmission torque of a separating or hybrid clutch of a hybrid drive

一种混合驱动、离合器的技术,应用在通用动力装置的多个不同原动机的布置、混合动力车辆、使用发动机驱动的牵引等方向,能够解决冲击、转速扰动等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

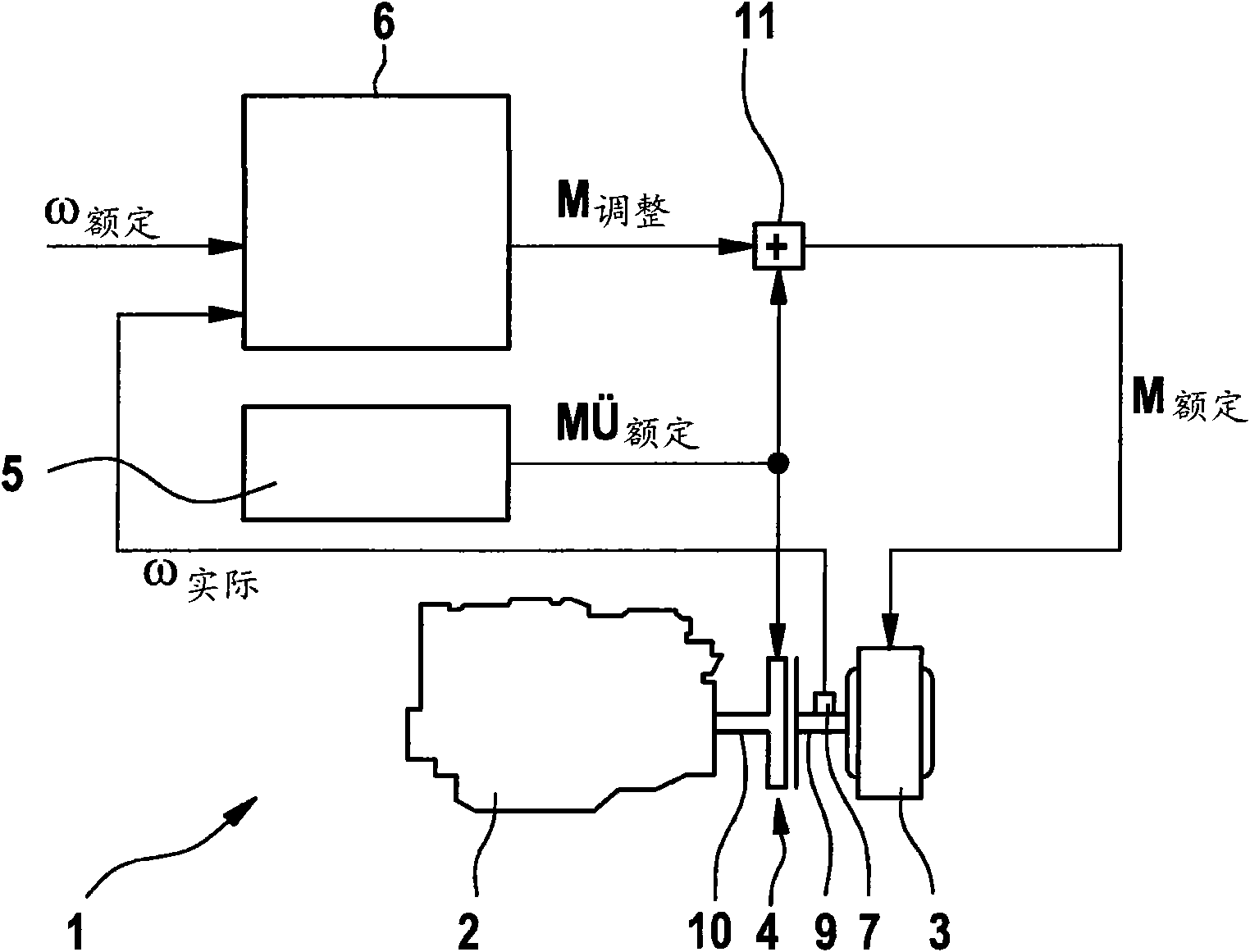

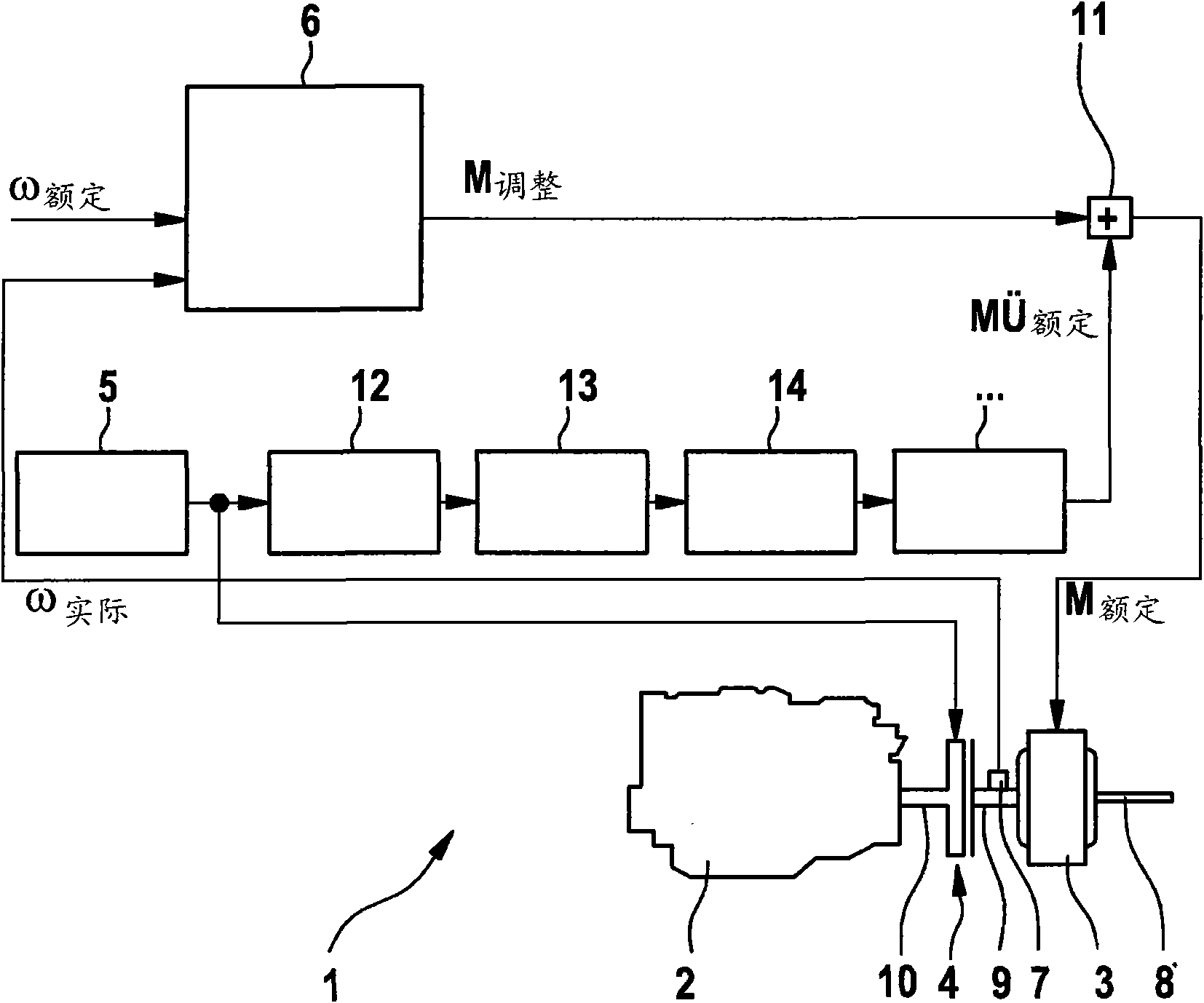

[0017] The hybrid drive 1 of a motor vehicle, shown only partially and schematically in the drawing, comprises an internal combustion engine 2 and an electric machine 3 , which the vehicle can use either purely electrically, that is to say only by means of the internal combustion engine 2 when the internal combustion engine 2 is switched off. The electric motor 3 is driven and / or when the electric motor 3 is switched off, it is driven exclusively by the internal combustion engine 2 and / or it is driven in a hybrid manner, that is, not only by the internal combustion engine 2 but also by the electric machine 3, the internal combustion engine 2 and the electric machine 3 In the last-mentioned case, the drive torque for the drive train 8 of the motor vehicle to the drive wheels of the motor vehicle is jointly provided.

[0018] Purely electric operation is generally preferred for low drive powers and only when a higher drive power is required or the capacity or state of charge of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com