Preparation technology of detachable welding type mold insert (core)

A preparation process and mold core technology, which is applied in the field of preparation technology of split welding mold cores, can solve the problems of prolonged mold opening and closing time, long processing cycle, easy to break position, etc., so as to improve the qualified rate of finished products, improve processing efficiency, The effect of reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further described in detail through the following embodiments in conjunction with the accompanying drawings, but the technical content described in this embodiment is illustrative rather than restrictive, and should not be used to limit the protection scope of the present invention.

[0023] A kind of preparation technology of split welding mold kernel (core), its steps are:

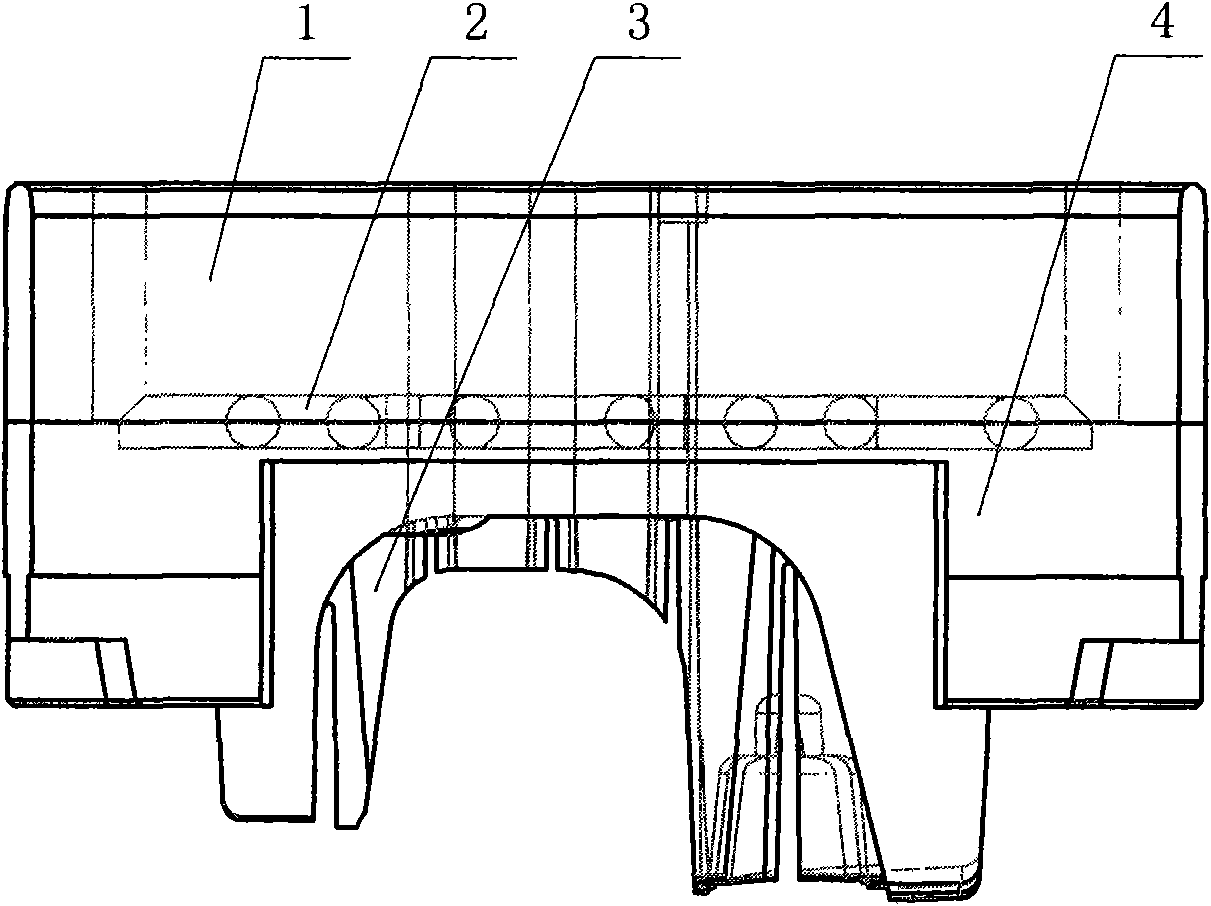

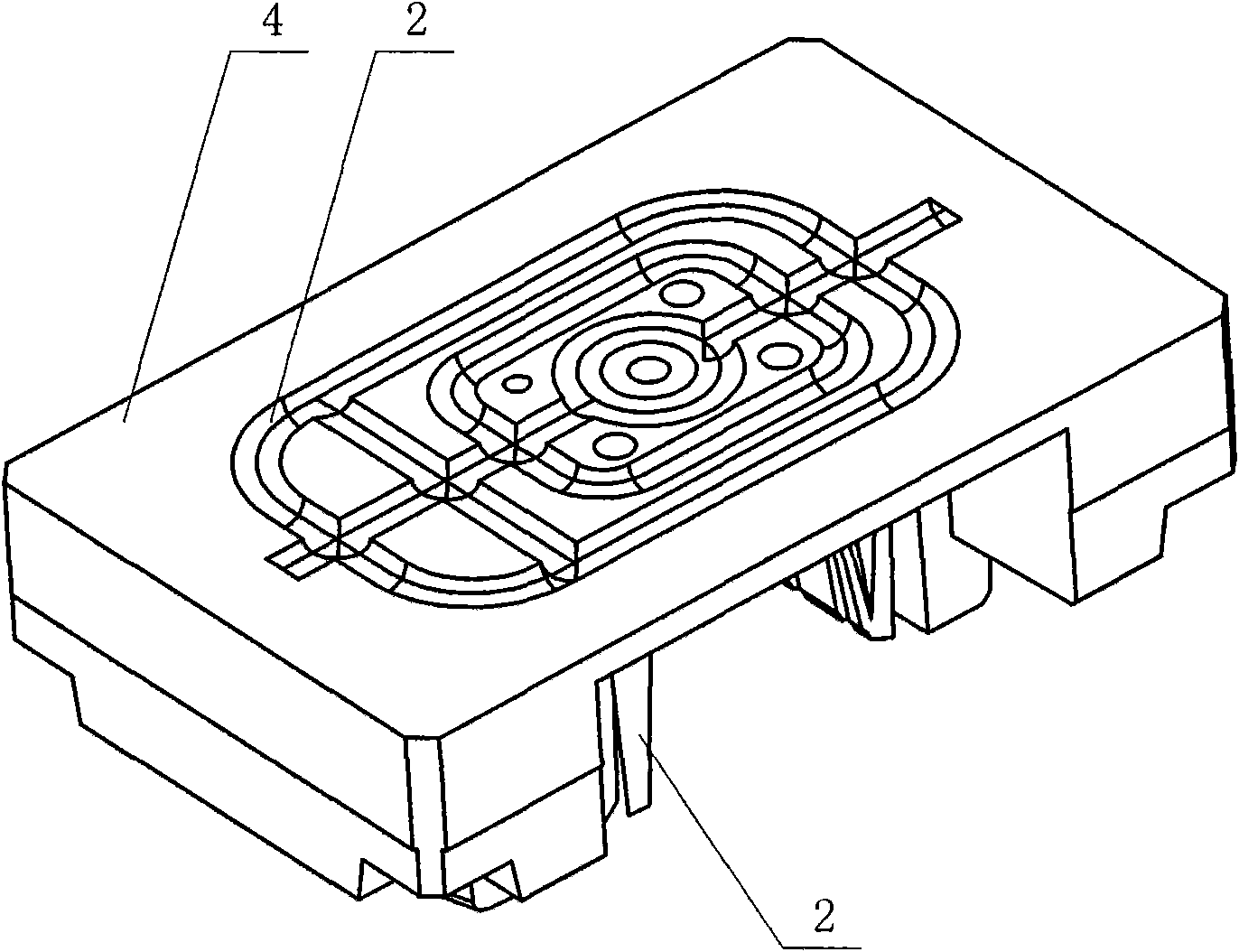

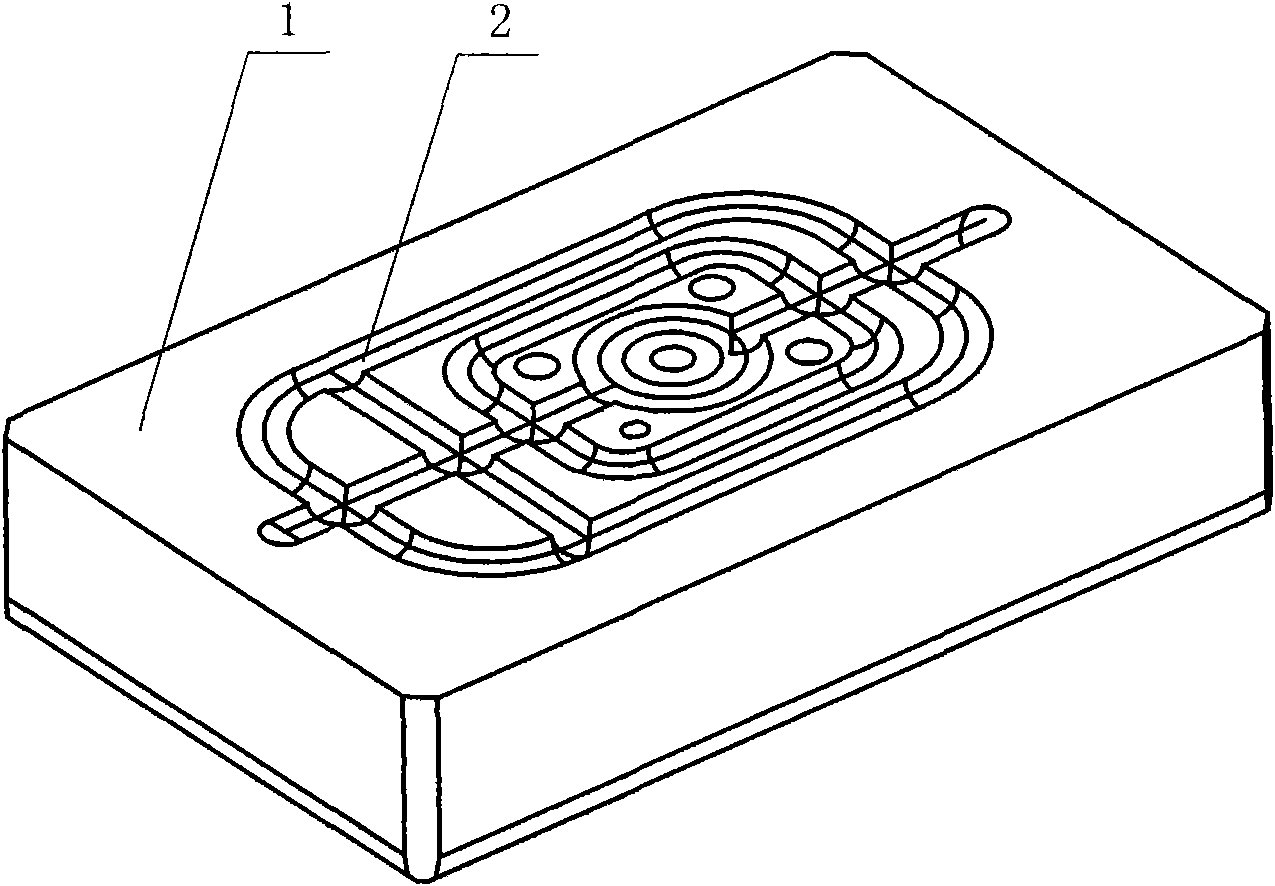

[0024] (1) The mold material is divided into A material plate 4 and B material plate 1, and the first conventional heat treatment is carried out, wherein the A material plate is a material plate with a cavity 3;

[0025] (2) Remove the margin of the A and B material plates after heat treatment, and process them for alignment, leaving a margin of 0.03-0.07mm on one side, preferably 0.05mm, and the equipment used is a precision surface grinder;

[0026] (3) Use the high-speed milling center to process the complex curved surface of the A material plate, leaving a margin of 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com