Rack for film delivery

A film and platform technology, applied in the direction of transportation and packaging, rigid containers, containers, etc., can solve the problems of core material deformation, core material damage, damage, etc., to reduce the contact area, the possibility of damage is low, and reliable The effect of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] (film roll)

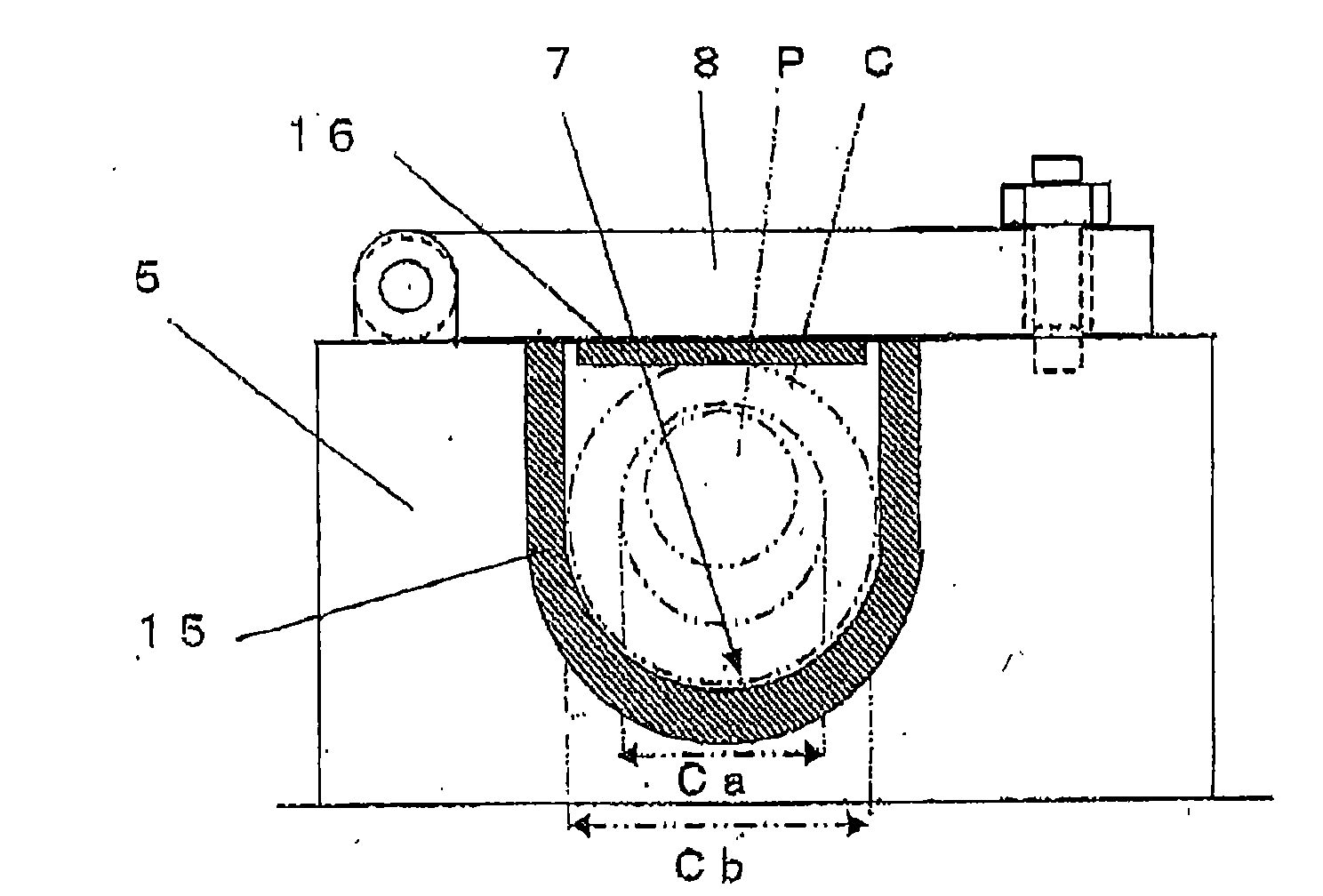

[0092] The film roll mounted on the stand for film conveyance of the present invention is a film roll in which a film having a width of 1 to 5 m is wound around a tubular core in an elongated shape. The diameter of the film roll is in the range of 30 to 150 cm. The loading and unloading of the film roll to the film transfer stand is carried out while penetrating the metal rod through the core material and holding both ends of the metal rod so that the film roll is suspended. During the conveyance of the film roll, the film roll is supported by the left and right ends of the core material and is suspended.

[0093] (Basic frame of film transfer stand)

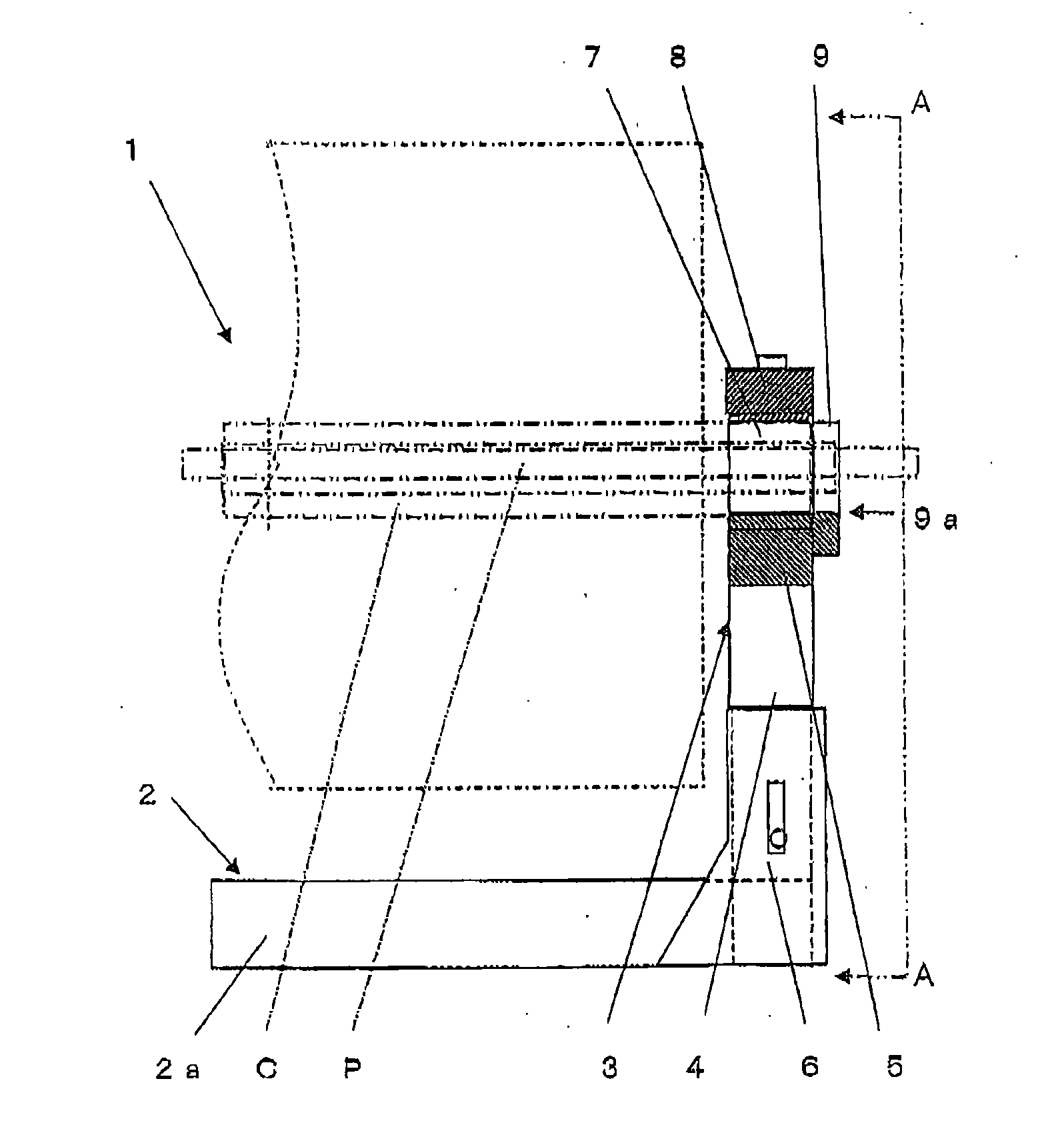

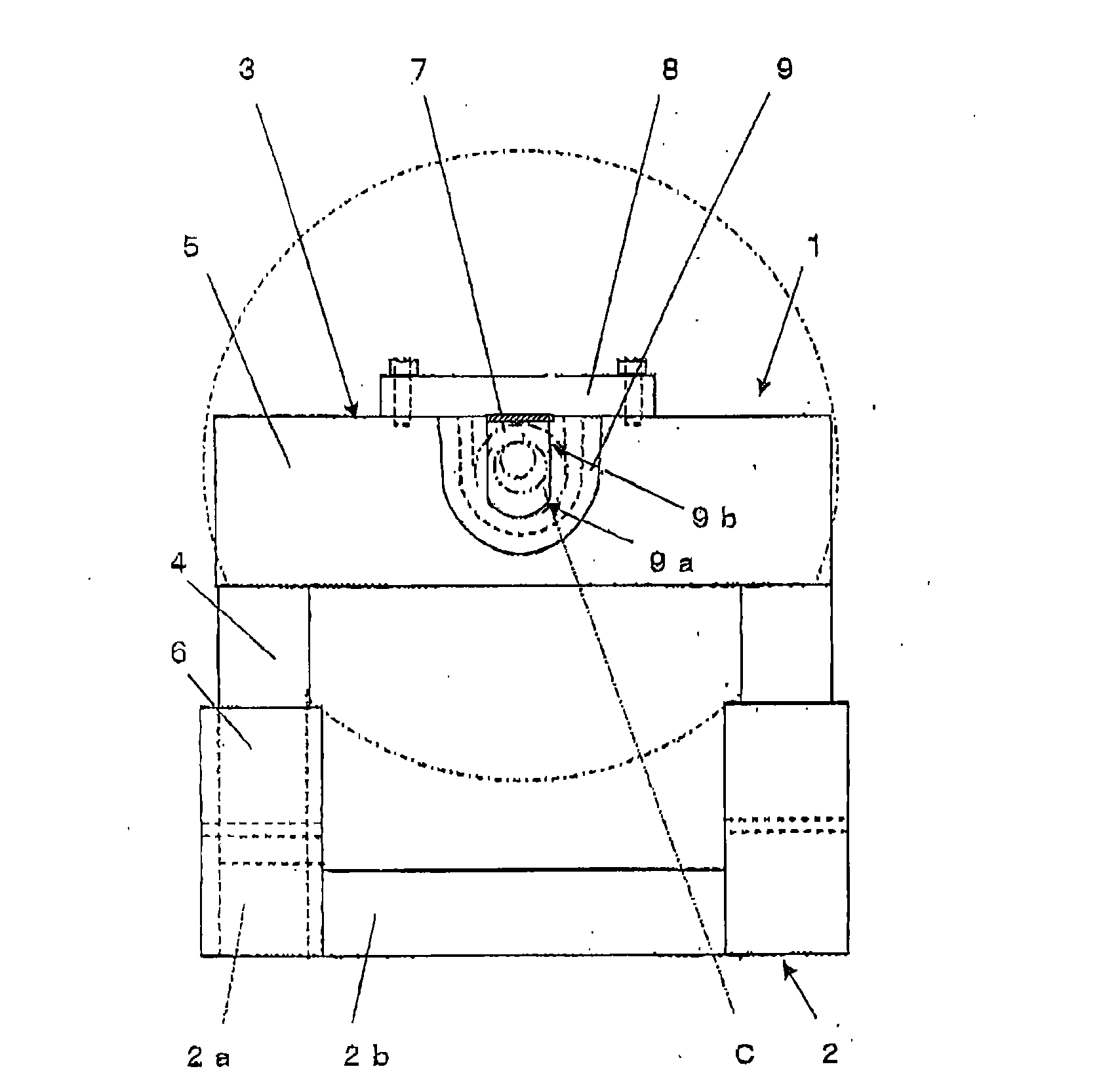

[0094] figure 1 and figure 2 An example of the film conveying stand of the present invention is shown. The frame 1 for conveying a film is composed of a rectangular pallet base 2, at least four pillar mounting parts 6 erected at the four corners of the pallet base, four pillars 4 mounted on the pillar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com