Chitosan-polylactic acid graft copolymer and preparation method and application thereof

A technology of graft copolymer and chitosan, which is applied in medical formula, medical preparation of non-active ingredients, medical science, etc., can solve the problems of polymers with biological toxicity, complex process route, insoluble, etc., and achieve excellent The effect of biocompatibility, good biocompatibility and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

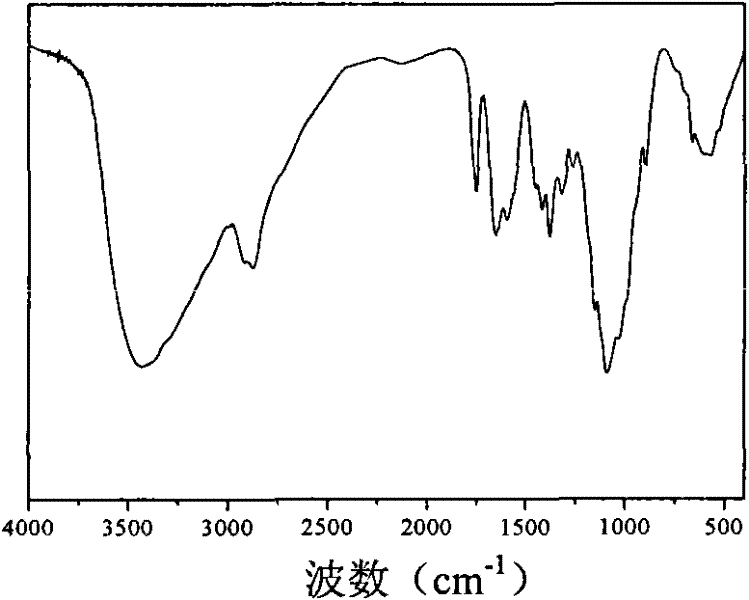

[0035] Under the catalysis of CCL, chitosan with a degree of deacetylation of 90% and lactide 1:10 (this is the molar ratio of the unit sugar ring number of chitosan to the lactide monomer, the same below).

[0036] Add 0.1118g of chitosan, 1.0000g of lactide and 0.0050g of CCL (put into a bag) into the reactor, seal it, pass carbon dioxide for about 30 minutes to remove the air in the reactor, then close the air inlet and outlet valves, and turn on the electromagnetic Stir and heat. When the temperature reaches 90°C, increase the pressure in the reactor and control it at 40MPa, start recording the reaction time, and the reaction ends after 24 hours; continue to keep the pressure in the reactor at 40MPa and the temperature at 90°C, open the inlet and outlet Air valve, extract a small amount of unreacted monomer (lactide) by supercritical carbon dioxide fluid extraction, until no white powder is ejected from the outlet of the air release valve, the extraction time is about 3h, r...

Embodiment 2

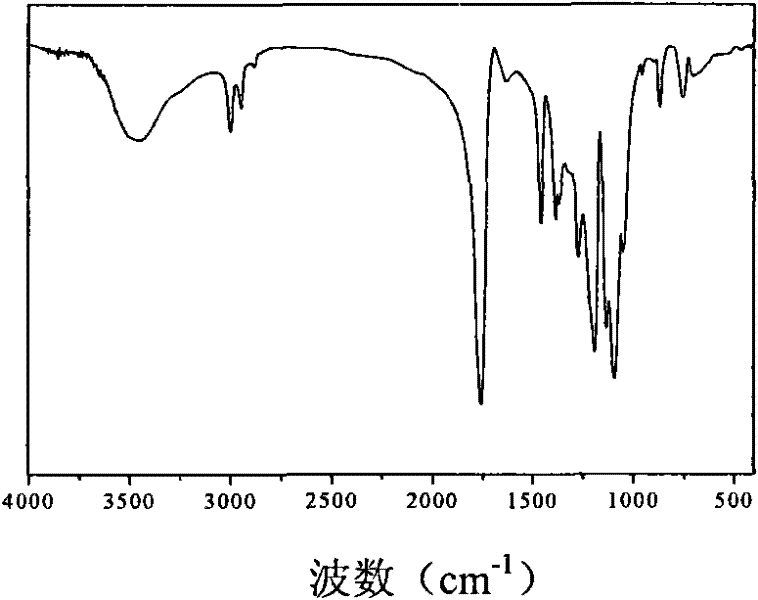

[0040] Implementation of 1:0.1 chitosan and lactide with a degree of deacetylation of 95% under PPL catalysis.

[0041] Add 5.5910g of chitosan, 0.5000g of lactide and 0.0500g of PPL (put into a bag) into the reactor, seal it, pass carbon dioxide for about 30 minutes to remove the air in the reactor, then close the air inlet and outlet valves, and turn on the electromagnetic Stir and heat. When the temperature reaches 60°C, increase the pressure in the reactor and control it at 25MPa, start recording the reaction time, and the reaction ends after 72 hours; continue to keep the pressure in the reactor at 25MPa and the temperature at 60°C, open the inlet and outlet Air valve, extract a small amount of unreacted monomer (lactide) by supercritical carbon dioxide fluid extraction, until no white powder is ejected from the outlet of the air release valve, the extraction time is about 2h, reduce the pressure of the reactor to atmospheric pressure, and then open the reaction The graft...

Embodiment 3

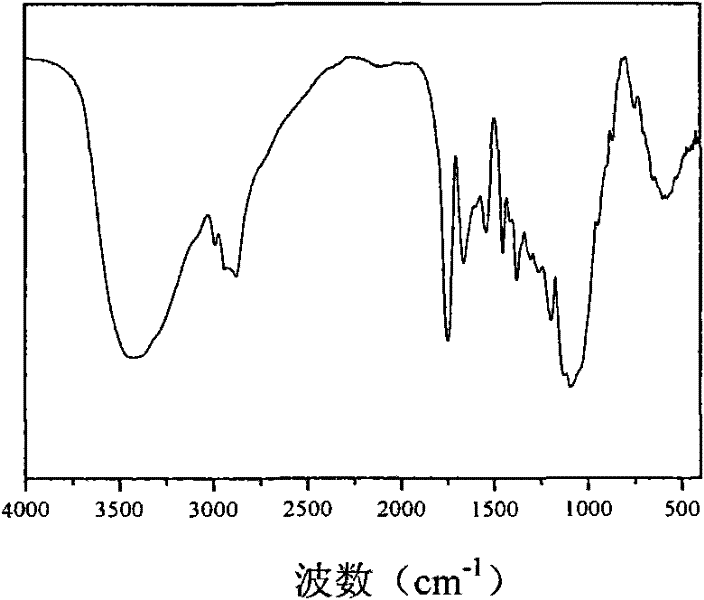

[0043] Implementation of 1:1 chitosan and lactide with a deacetylation degree of 90% under PPL catalysis.

[0044] Add 1.1182g of chitosan, 1.000g of lactide and 0.0200g of PPL (put into the bag) into the reactor, seal it, pass carbon dioxide for about 30 minutes to remove the air in the reactor, then close the air inlet and outlet valves, and turn on the electromagnetic Stir and heat. When the temperature reaches 80°C, increase the pressure in the reactor and control it at 30MPa, start recording the reaction time, and the reaction ends after 24 hours; continue to keep the pressure in the reactor at 30MPa and the temperature at 80°C, open the inlet and outlet Air valve, extract a small amount of unreacted monomer (lactide) by supercritical carbon dioxide fluid extraction, until no white powder is ejected from the outlet of the air release valve, the extraction time is about 4h, reduce the pressure of the reactor to atmospheric pressure, and then open the reaction The graft cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com