Washing machine with self-cleaning function

A washing machine and self-cleaning technology, applied in other washing machines, washing devices, household appliances, etc., can solve the problems of secondary pollution, generation of dirt and odor, affecting the health of users, etc., and achieve the effect of preventing dirt residue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

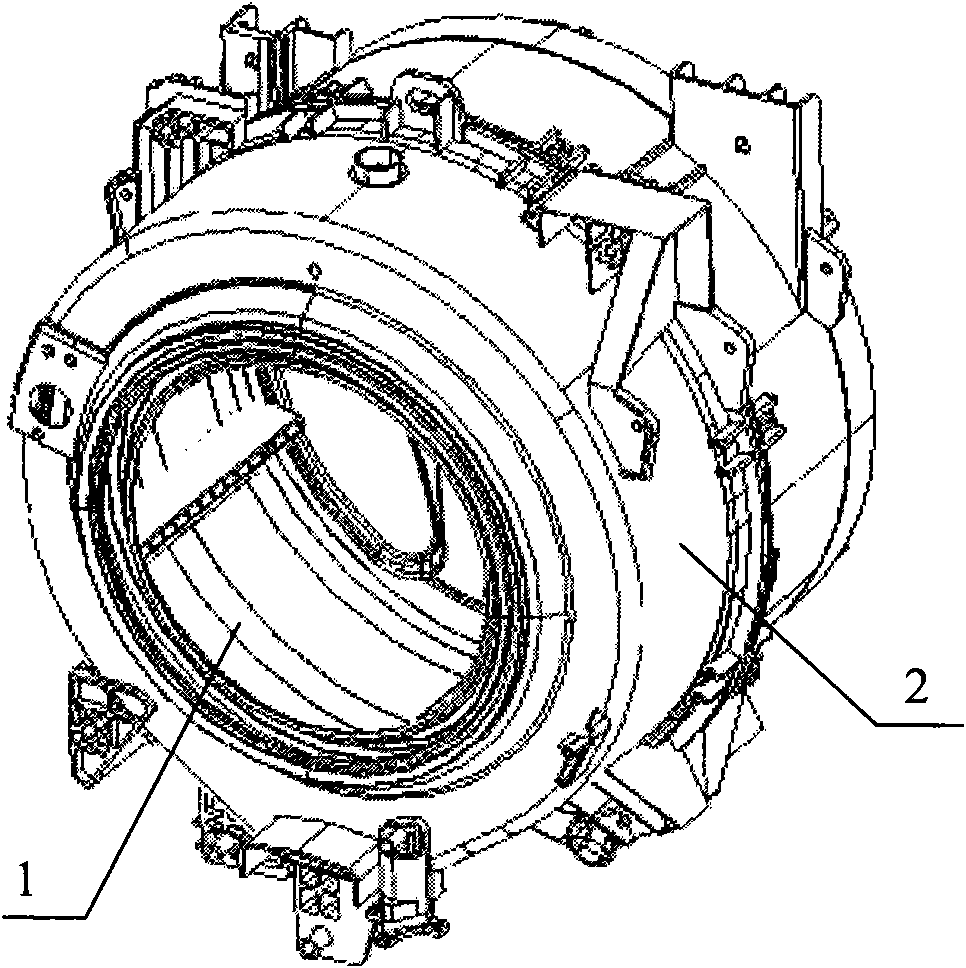

[0016] Such as figure 1 As shown, a washing machine with self-cleaning function of the present invention mainly includes a washing tub 1 and a water tub 2 .

[0017] It uses non-hydrophilic plastic materials to form the outer surface of the washing tub 1 and the inner surface of the water tub 2, and utilizes the surface tension of the molecular structure when the plastic material is formed to reduce the surface energy of the plastic.

[0018] The low surface energy material used in the present invention can be plastics with low surface energy such as PP, PE, PET or PTFE. At the same time, in order to reduce the surface energy of the product surface, the surface is formed by spray or blow molding process.

[0019] The plastic materials used for the outer surface of the washing tub 1 and the inner surface of the water tub 2 are formed by blow m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com