Reducing nosie, vibration and harshness in a variable displacement engine

An engine and braking mechanism technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve problems such as reducing fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

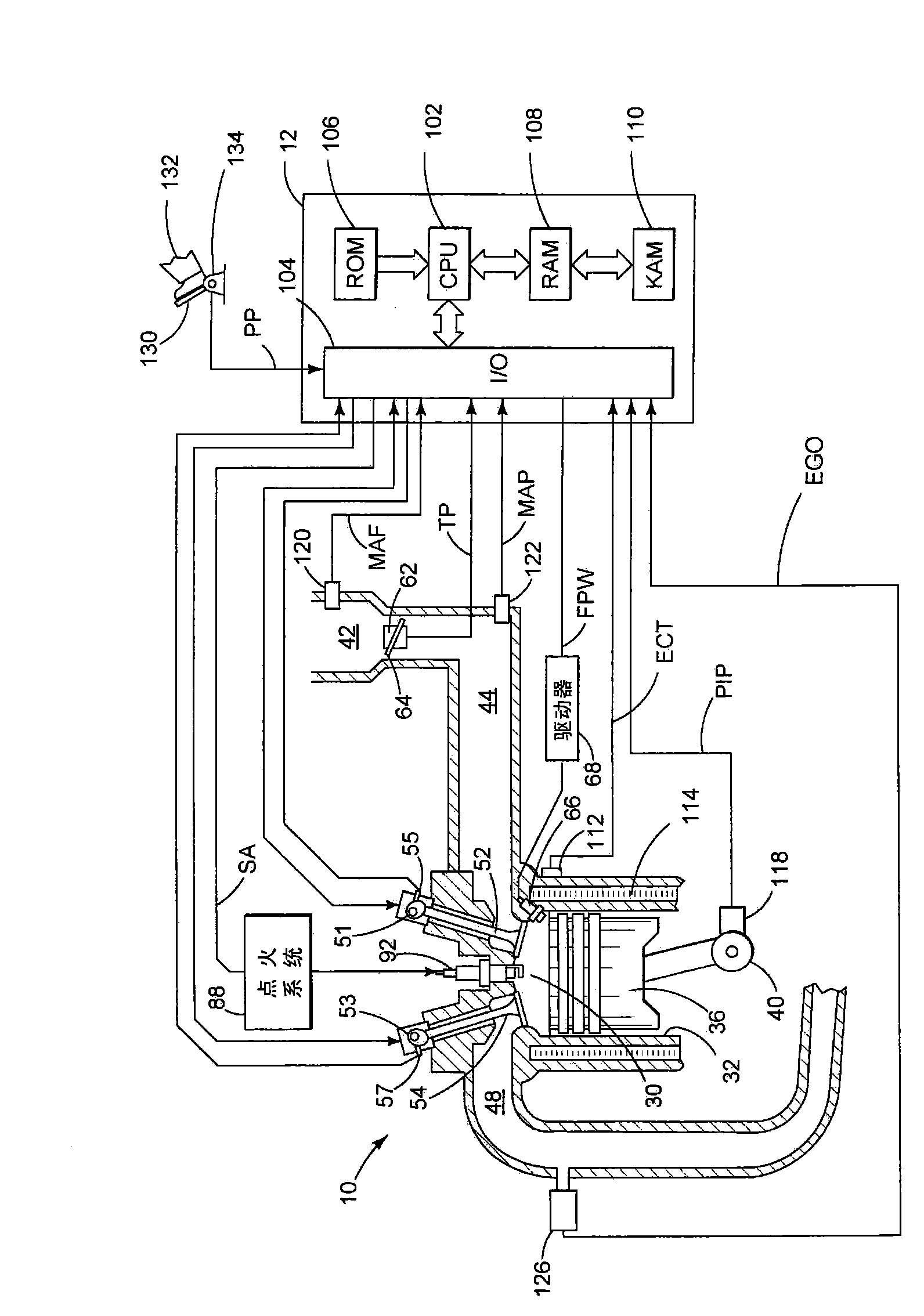

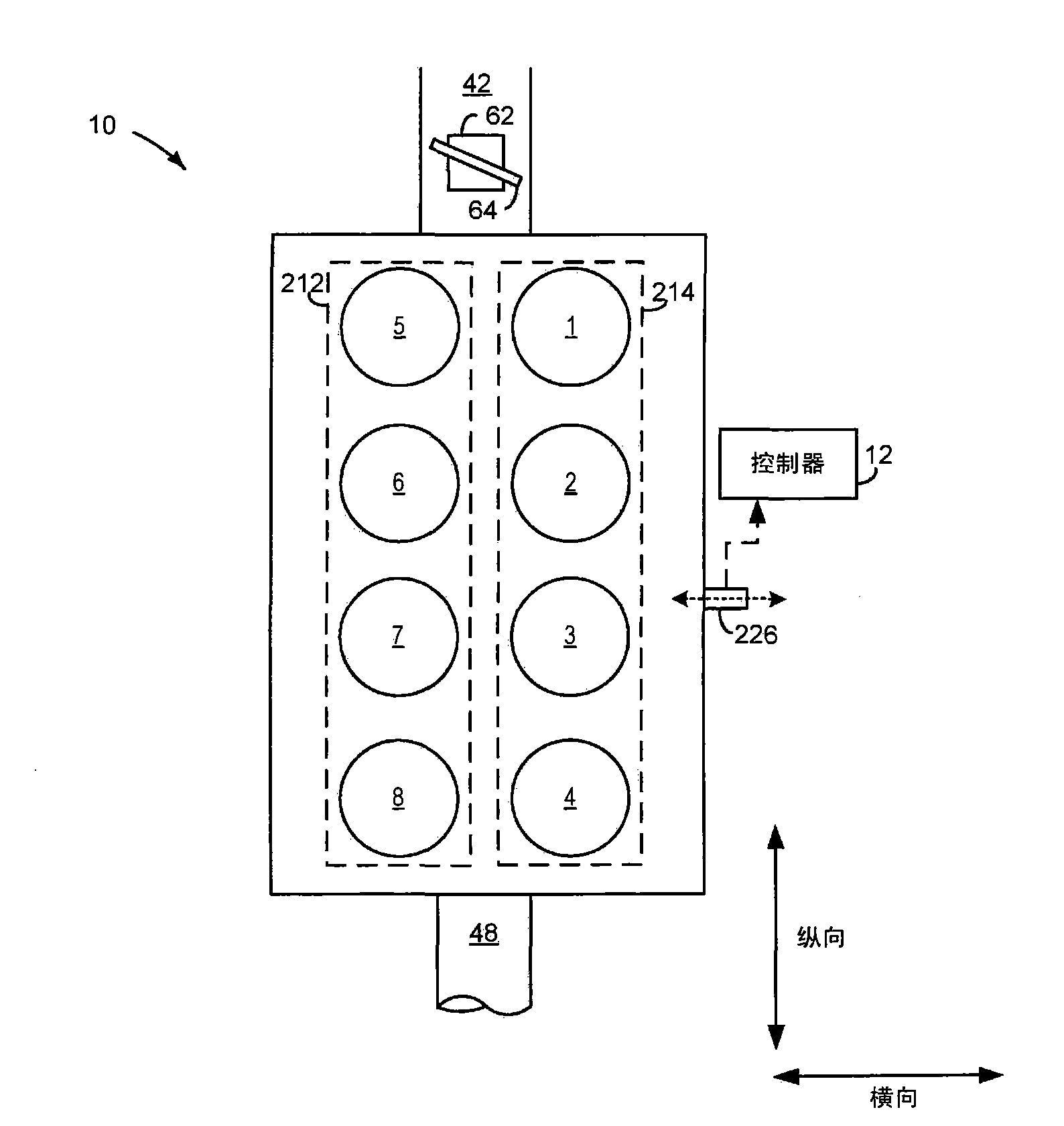

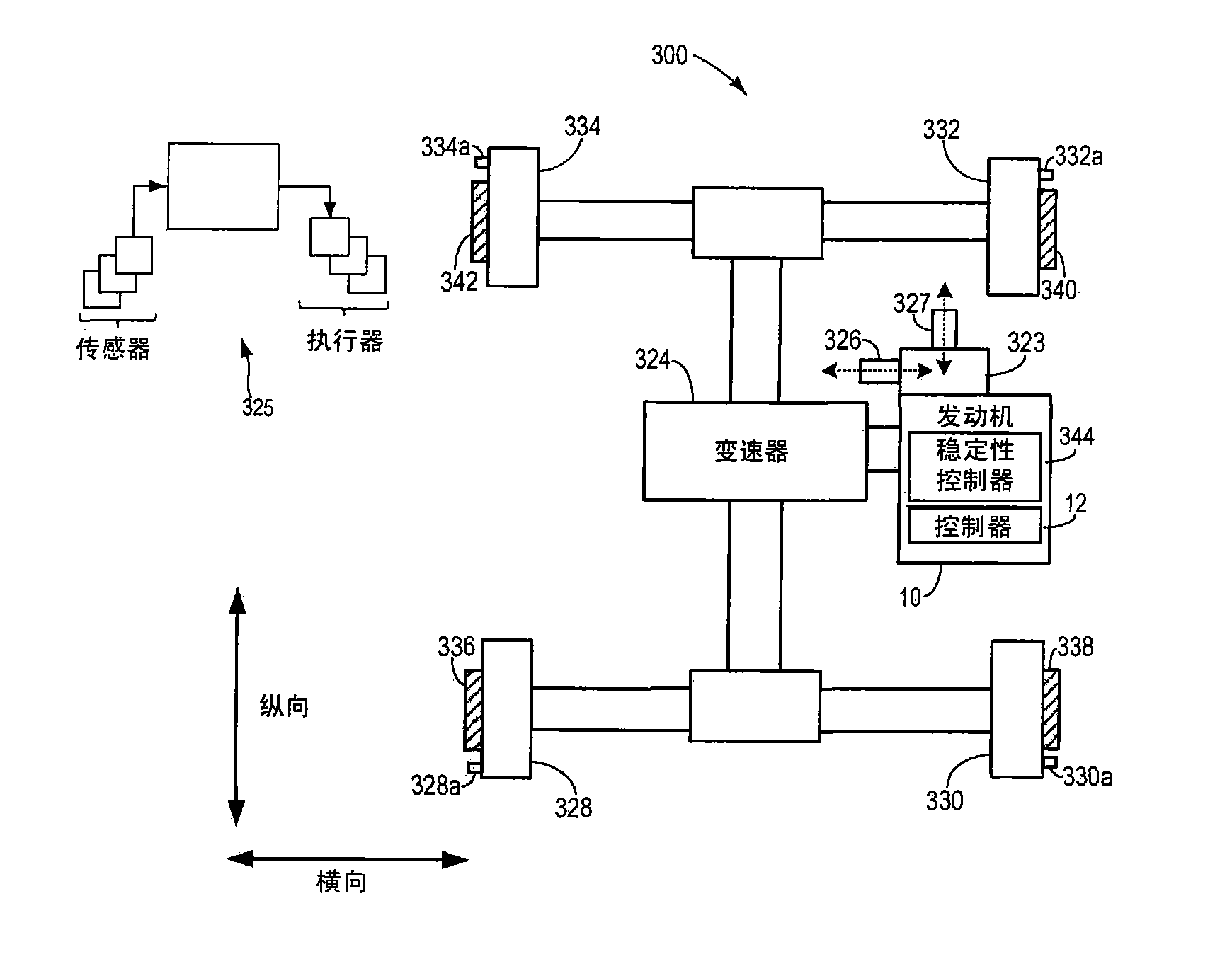

[0017] The vehicle system described herein has an engine with cylinder deactivation and electronic vehicle stability control, where an acceleration sensor provides information both for activating / deactivating cylinders of the engine and for controlling the vehicle to maintain stability during various operations . For example, one or more vehicle brakes may be automatically controlled using yaw sensor information to reduce the vehicle's roll tendency during cornering conditions. In addition, sensor information (after bandpass filtering) can also be used to identify engine vibrations during cylinder deactivation conditions. Based on these identified operating conditions, the engine may be controlled to restart one or more cylinders to mitigate the detected vibrations. In this way, a common acceleration sensor can be used to improve two separate applications. Additionally, sensor information may be used to inhibit deactivation of one or more cylinders if engine operation is uns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com