Gas compressor

A compressor and shell technology, applied in the field of compressors, can solve the problems of unstable output flow and pressure, and achieve the effects of stable pressure, less consumables, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

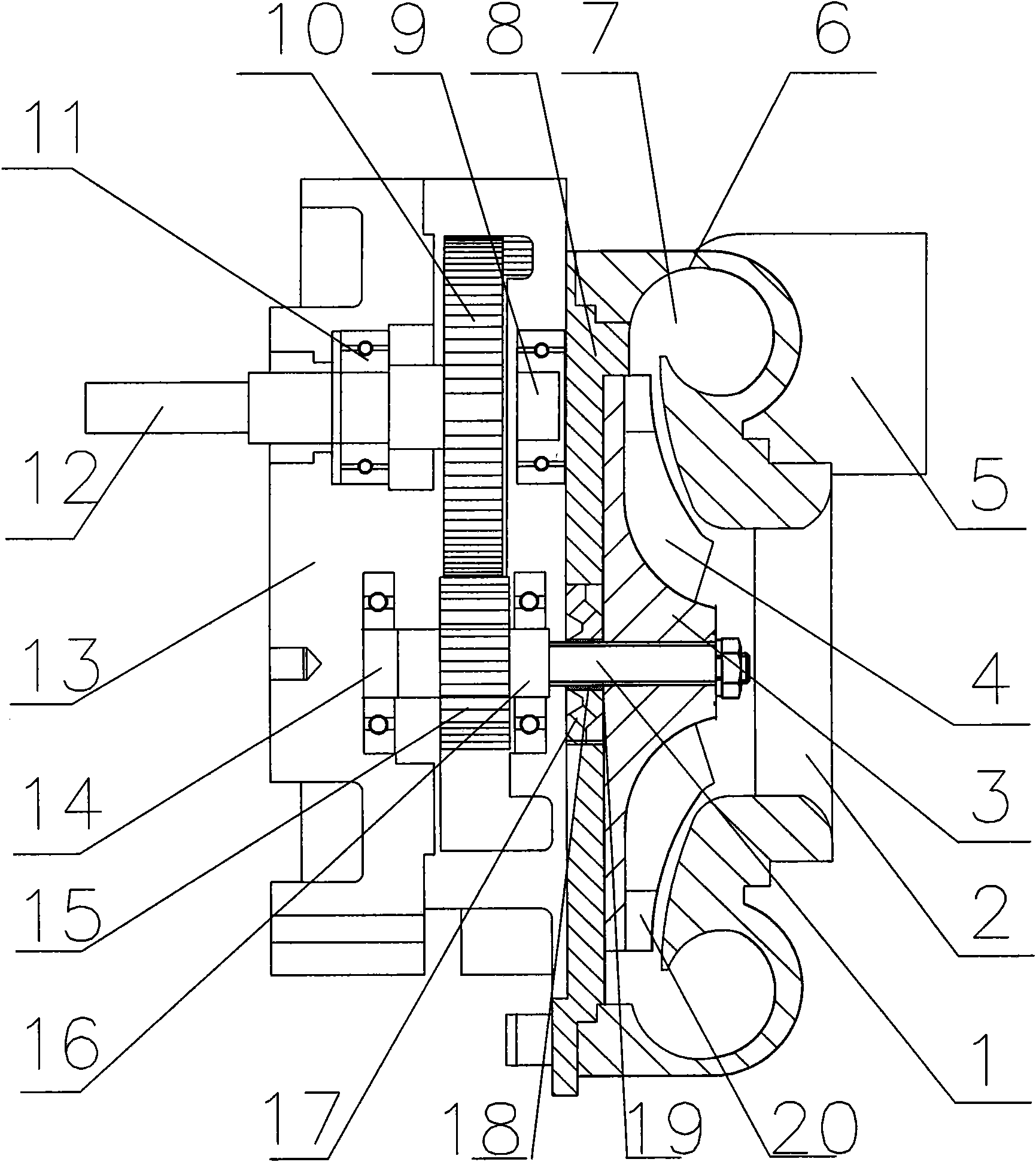

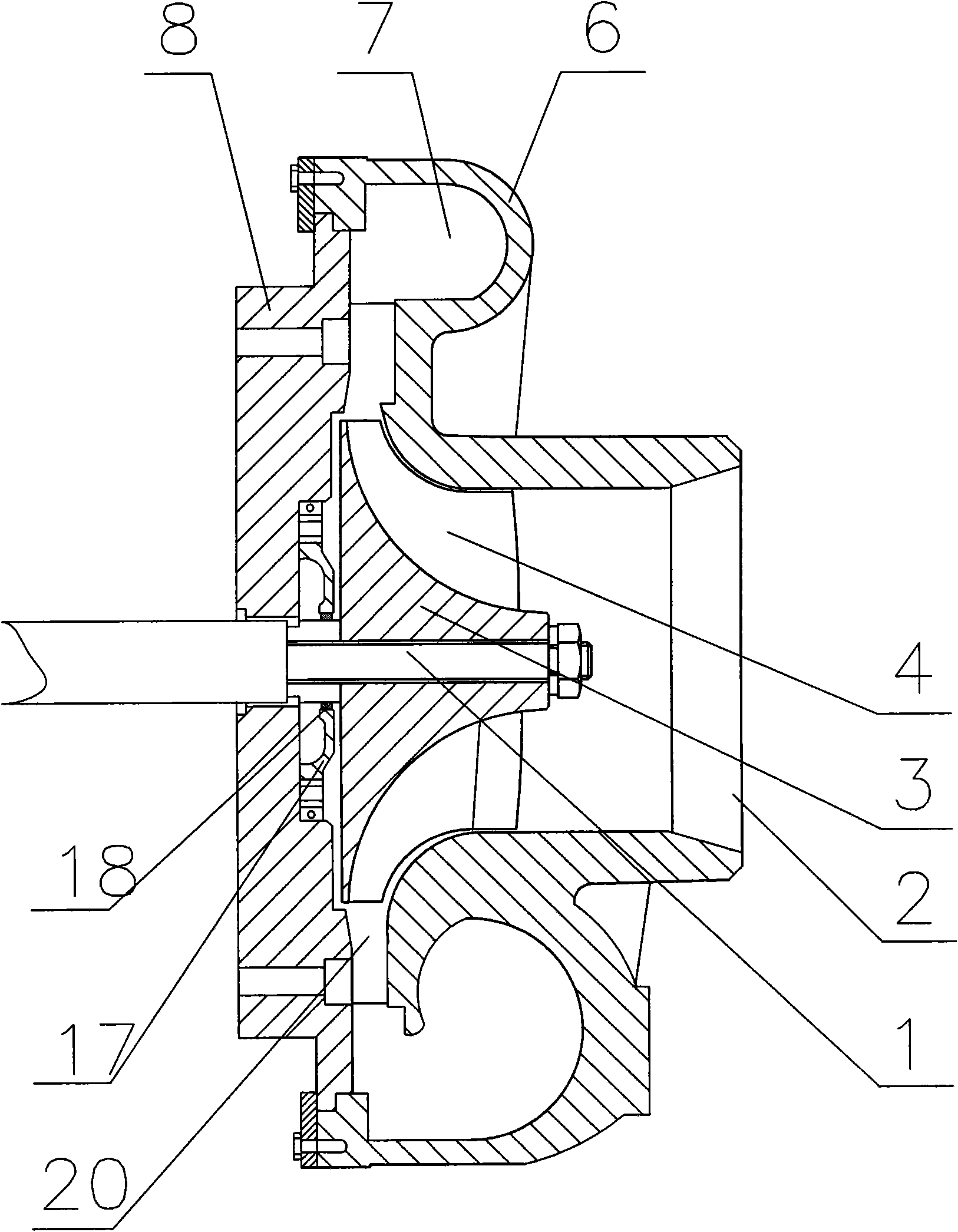

[0026] A compressor includes a variable speed transmission mechanism and a compressor mechanism.

[0027] The compressor mechanism includes a casing 6, an impeller 3 and a rear plate 8; the impeller 3 is installed at the front end of the wheel shaft 1, the wheel shaft 1 is fixedly connected with the impeller 3, the impeller 3 is provided with a blade 4, and the impeller 3 and the blade 4 are integrally connected; the impeller 3 is located in the center of the housing 6, the front end of the center of the housing 6 is provided with an air inlet 2, and the rear end of the center of the housing 6 is provided with a finished vane diffuser 20, and the vane diffuser 20 is passed through by hot pressing. Heating, expanding, and extruding the sleeve to the rear end of the center of the casing 6, and cooling after normal temperature to make the bladed diffuser 20 and the casing 6 fixedly connected. An air outlet 5 is arranged on the outer periphery of the body 6, and a rear plate 8 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap