Sealing system

A sealing system and sealing element technology, which is applied in the direction of charging system, hose connection device, combustion air/combustion-air treatment, etc., can solve the problems of high manufacturing cost and assembly difficulty, and achieve the goal of avoiding assembly errors and saving time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

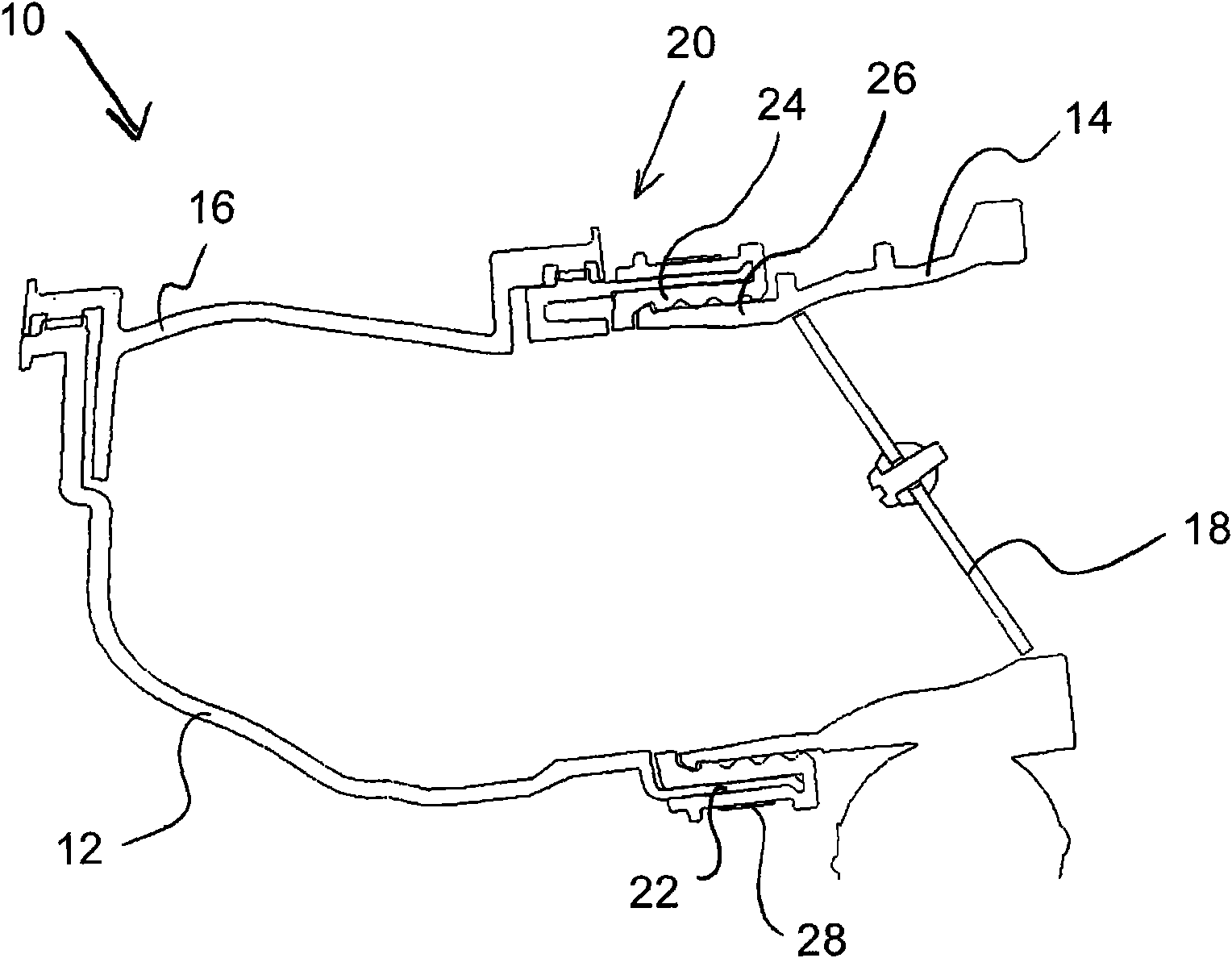

[0020] exist figure 1 The air intake line 10 shown in FIG. 1 has a gas filling tube 12 which is connected to a throttle tube 14 . In the embodiment shown, the filling tube 12 is multi-segmented and has a cover 16 so that the interior of the filling tube 12 is accessible. The fresh air sucked in through the charging line 12 can be throttled inside the throttle line 14 by means of a throttle valve 18 .

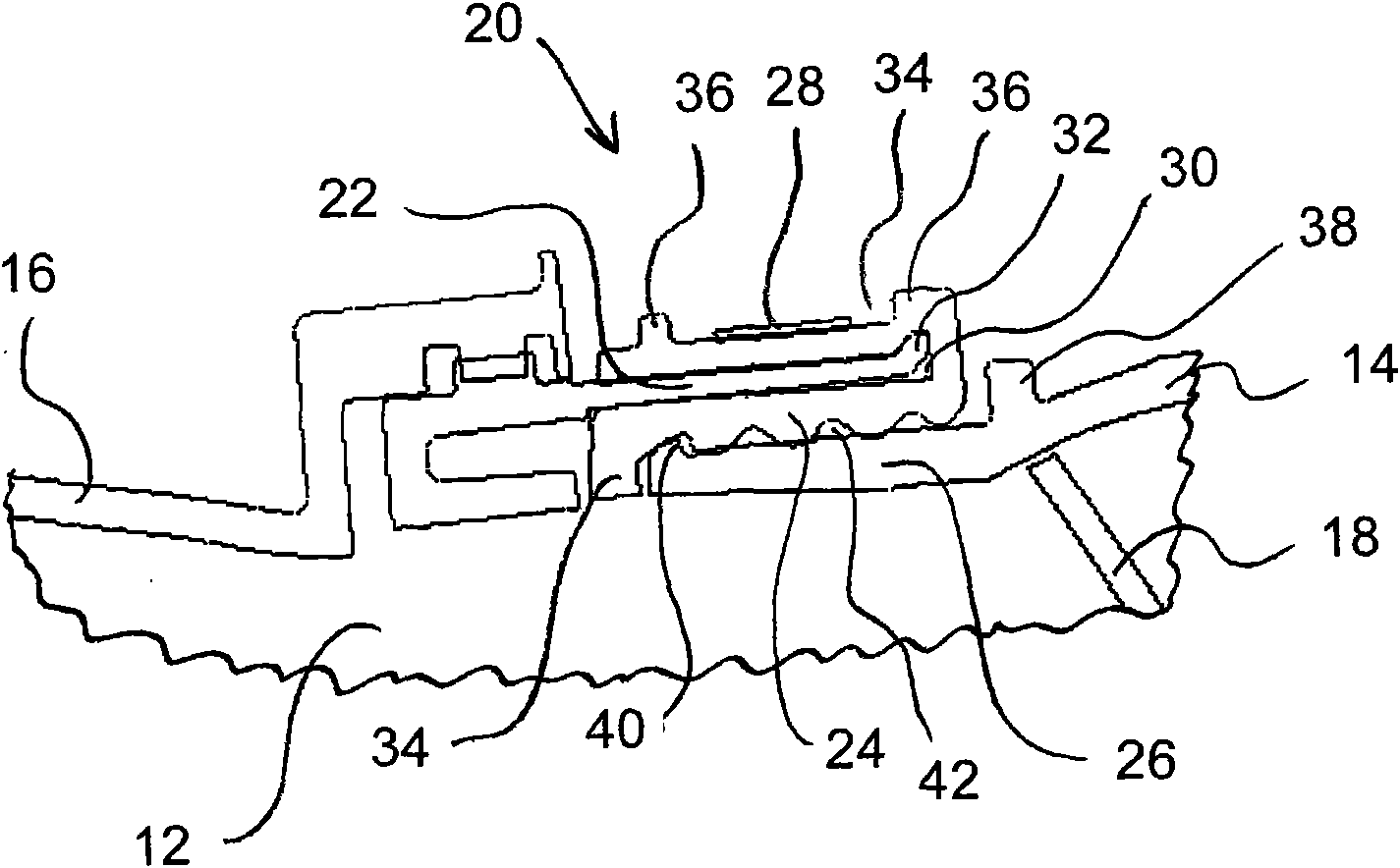

[0021] The gas tube 12 is connected to the throttle tube 14 in an essentially gas-tight manner via a sealing system 20 . For this purpose, the filling tube 12 has a connection fitting 22 which is connected via a sealing element 24 to a socket 26 of the throttle tube 14 . The required clamping force is exerted radially via the hose clamp 28 .

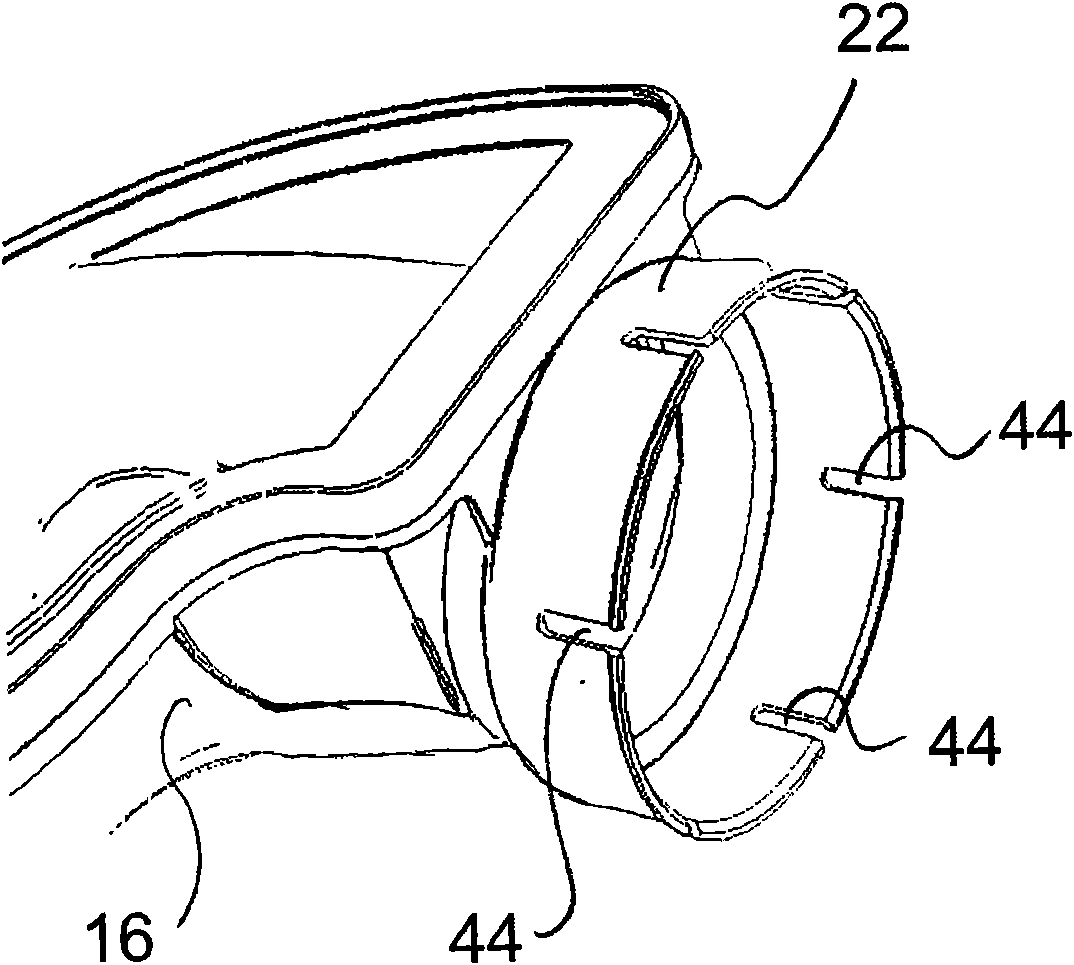

[0022] like figure 2 As shown, the sealing element 24 has a receiving recess 30 into which the connecting attachment 22 is inserted. The sealing element 24 is thus arranged facing the connection accessory 22 both on the inside and fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com