System and method for determining thin-film stress based on deformation measurement and numerical reverse

A technology of film stress and measurement value, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problems of difficult measurement, not considering the coordination conditions between the substrate and the film, and unable to measure the kinematic variables of all nodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

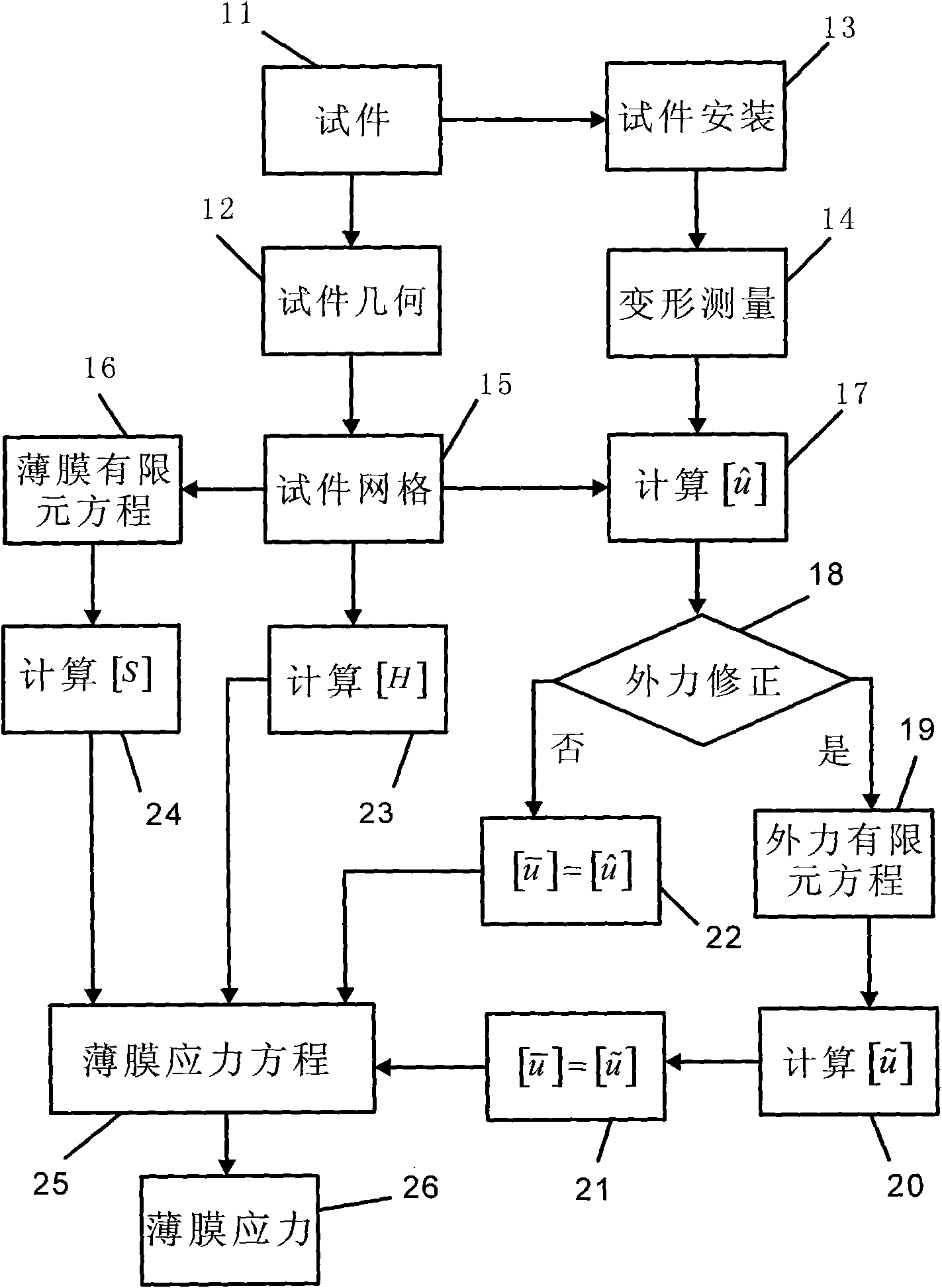

[0056] Illustrate the embodiment of the present invention by example below: Consider a rectangular base material (such as Figure 6 shown), its size is 30mm×20mm×70μm, Young’s modulus is 290GPa, Poisson’s ratio is 0.32, density is 2.3290g / cm 3 . A transverse film band with a width of 2 mm and a thickness of 0.7 µm was formed at a distance of 12 mm from the left boundary in the longitudinal direction. The film stress prediction steps are as follows:

[0057] (1) The user installs the substrate without film and the film material with film respectively on the measuring platform along the given direction;

[0058] (2) Measure the profile data of the matrix when there is no film and the profile data of the matrix when there is a film, respectively, with a shape measuring device;

[0059] (3) compare the shape data obtained by two kinds of measurements with a calculation program to obtain the change amount of the film material profile;

[0060] (4) Carry out geometric modeling a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com