Liquid crystal display panel

A liquid crystal display panel and liquid crystal layer technology, applied in static indicators, optics, instruments, etc., can solve problems such as low reliability of display panels, interference of electronic products, abnormality of substrate circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0045] In the first embodiment, the electrostatic protection structure includes a first wiring. The first wiring is arranged on the thin film transistor substrate and surrounds the edge of the thin film transistor substrate.

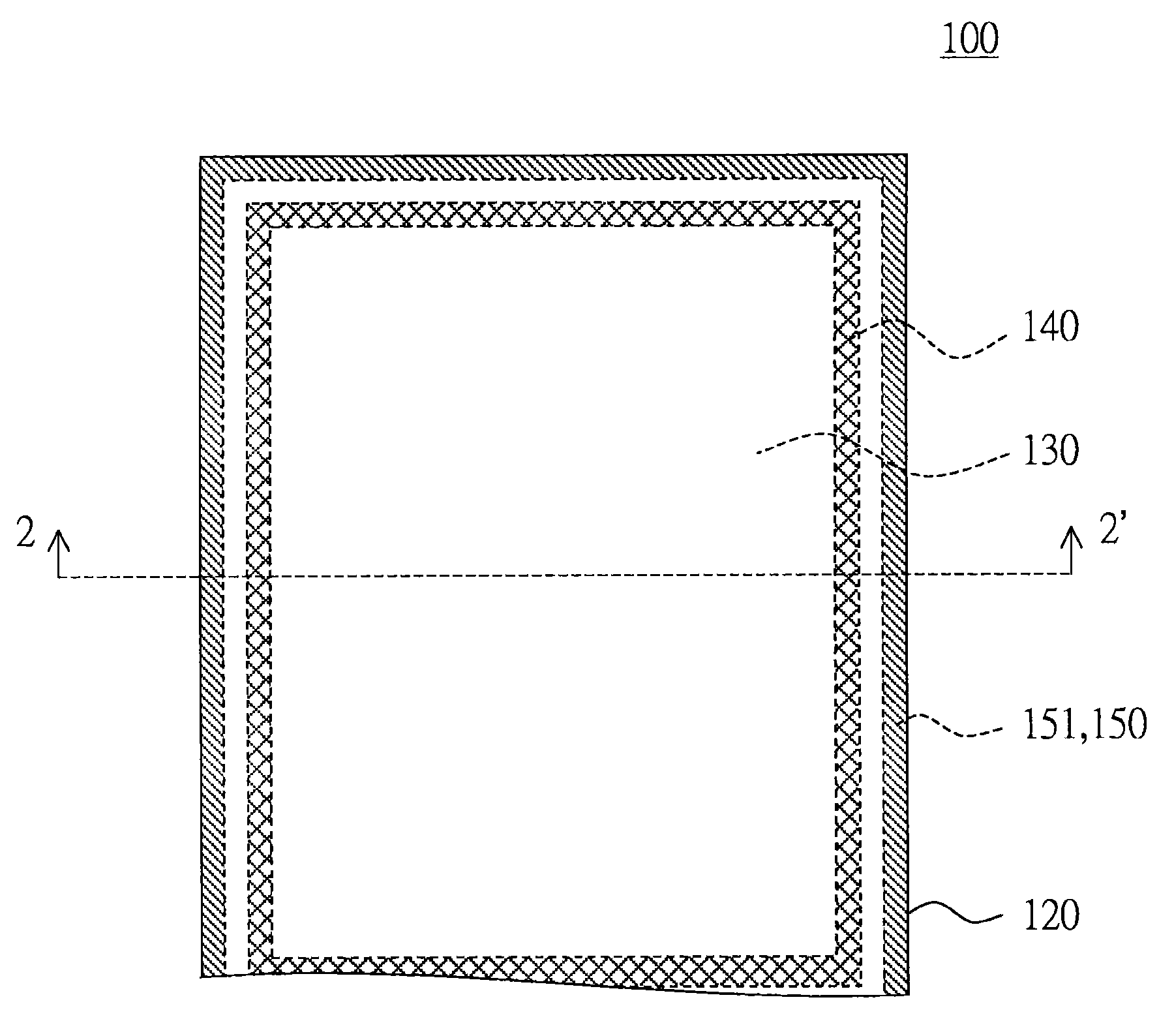

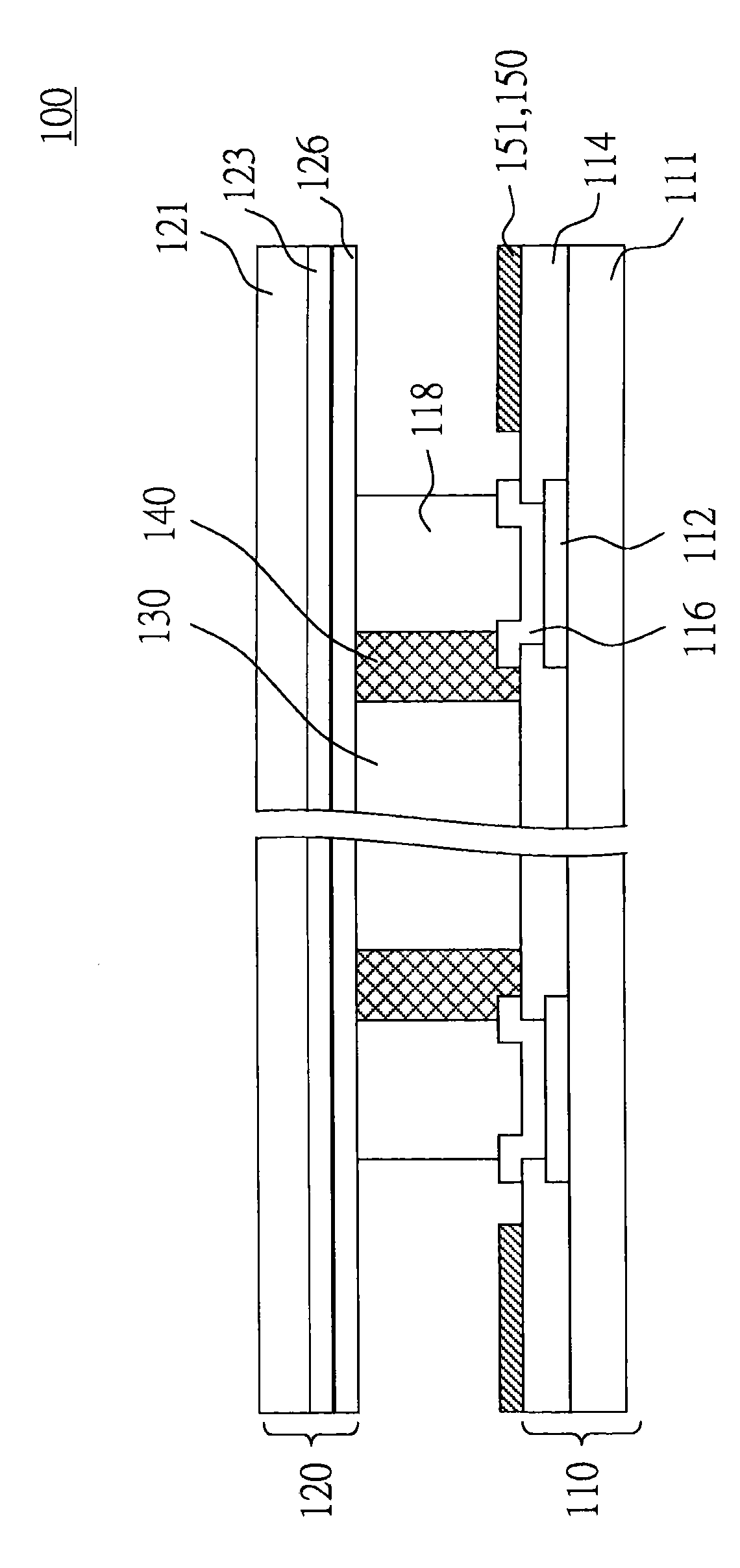

[0046] Please also refer to figure 1 and figure 2 , figure 1 A schematic diagram showing part of a liquid crystal display panel according to the first embodiment of the present invention, figure 2 draw figure 1 The sectional view of the liquid crystal display panel at section line 2-2'. The liquid crystal display panel 100 includes a thin film transistor substrate 110 , a color filter substrate 120 , a liquid crystal layer 130 , a sealant 140 and an electrostatic protection structure 150 . The TFT substrate 110 and the color filter substrate 120 are arranged parallel to each other. The sealant 140 seals the liquid crystal layer 130 between the TFT substrate 110 and the color filter substrate 120 . The area inside the sealant 140 is the display a...

no. 2 example

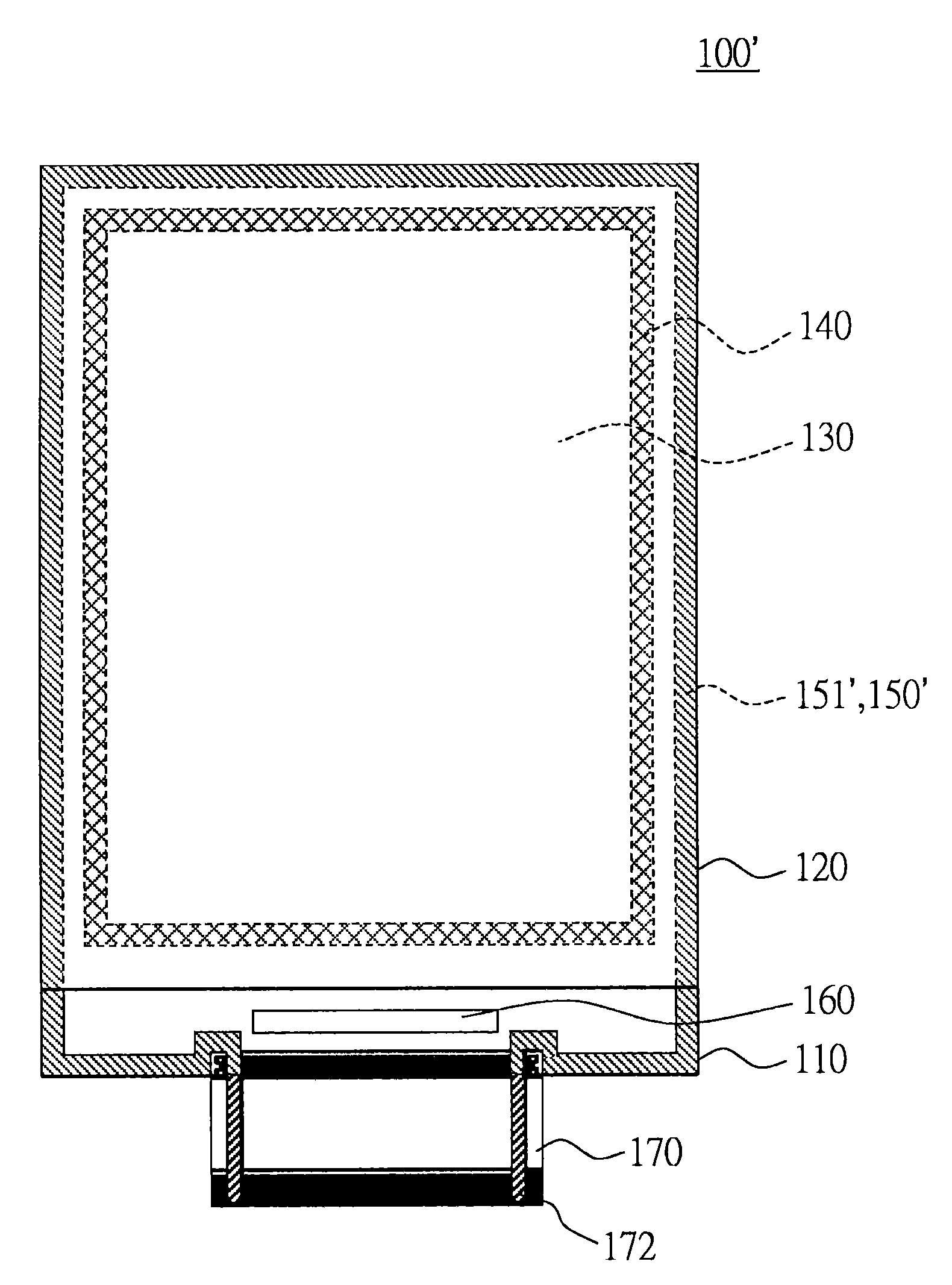

[0052] The difference between the second embodiment and the above-mentioned first embodiment lies in the arrangement relationship between the common electrode wiring and the electrostatic protection structure. In the second embodiment, the static electricity protection capability of the liquid crystal display panel is further enhanced by changing the arrangement relationship between the common electrode wiring and the static electricity protection structure. Please refer to Figure 5 , which shows a cross-sectional view of a liquid crystal display panel according to a second embodiment of the present invention. Figure 5 can be regarded as figure 2 The similar components use similar symbols, so the function and structural relationship of the similar components will not be repeated below.

[0053] exist Figure 5 Among them, the first trace 251 and the common electrode trace 212 are partially overlapped and electrically insulated, so as to form a capacitive structure at the...

no. 3 example

[0055] The difference between the third embodiment and the above-mentioned second embodiment is that there is a metal layer between the first trace and the common electrode trace. In this embodiment, the equivalent capacitance value of the capacitor structure is increased by using the above metal layer, so as to further enhance the electrostatic protection capability of the liquid crystal display panel. Please refer to Figure 6 , which shows a cross-sectional view of a liquid crystal display panel according to a third embodiment of the present invention. Figure 6 can be regarded as Figure 5 The similar components use similar symbols, so the function and structural relationship of the similar components will not be repeated below.

[0056] exist Figure 6 Among them, the electrostatic protection structure 350 further includes a metal layer 353 located between the first trace 351 and the common electrode trace 312 , and part of the metal layer 353 is covered by the insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com