Littrow-structural grating external cavity semiconductor laser and frequency tuning method

A frequency tuning, semiconductor technology, applied in the field of Littrow structure grating feedback external cavity semiconductor laser, can solve problems such as disadvantages, achieve the effect of stable beam position and reducing translation change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described more fully hereinafter with reference to the accompanying drawings, in which exemplary embodiments of the invention are illustrated.

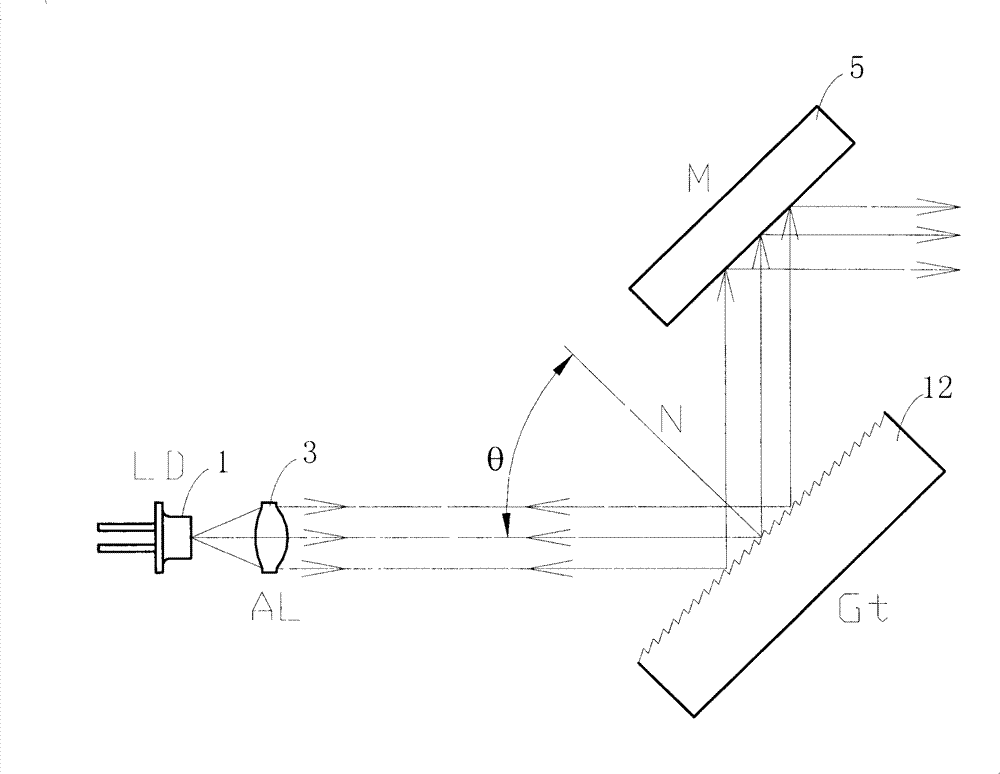

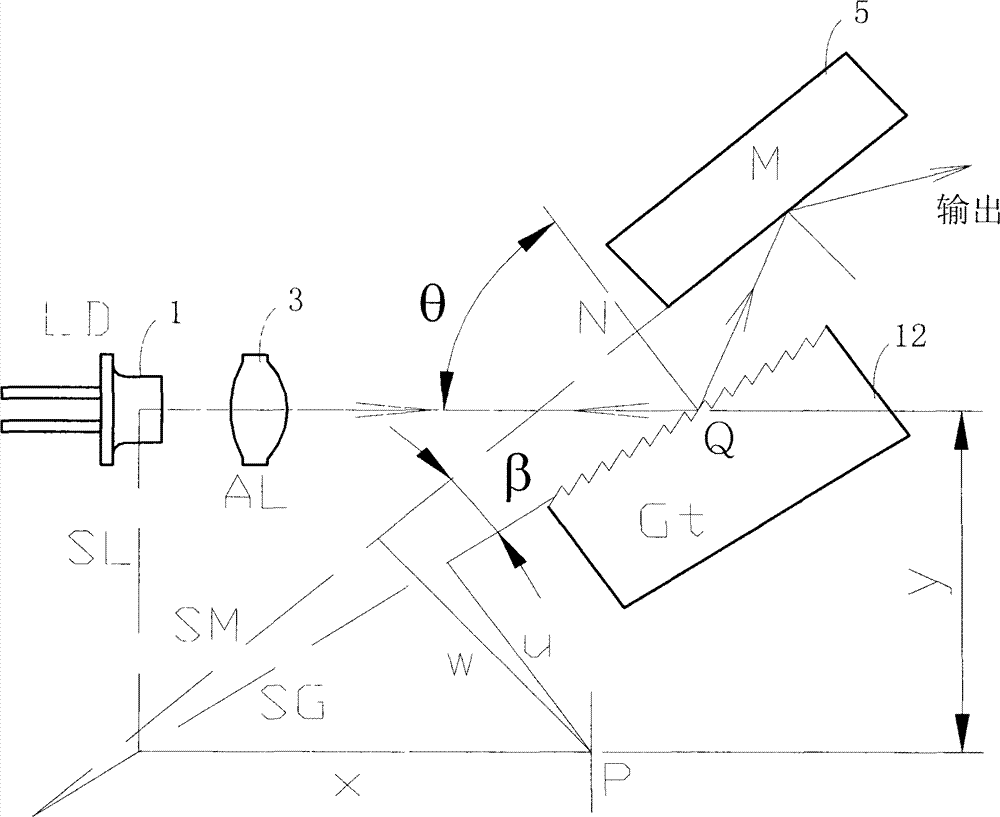

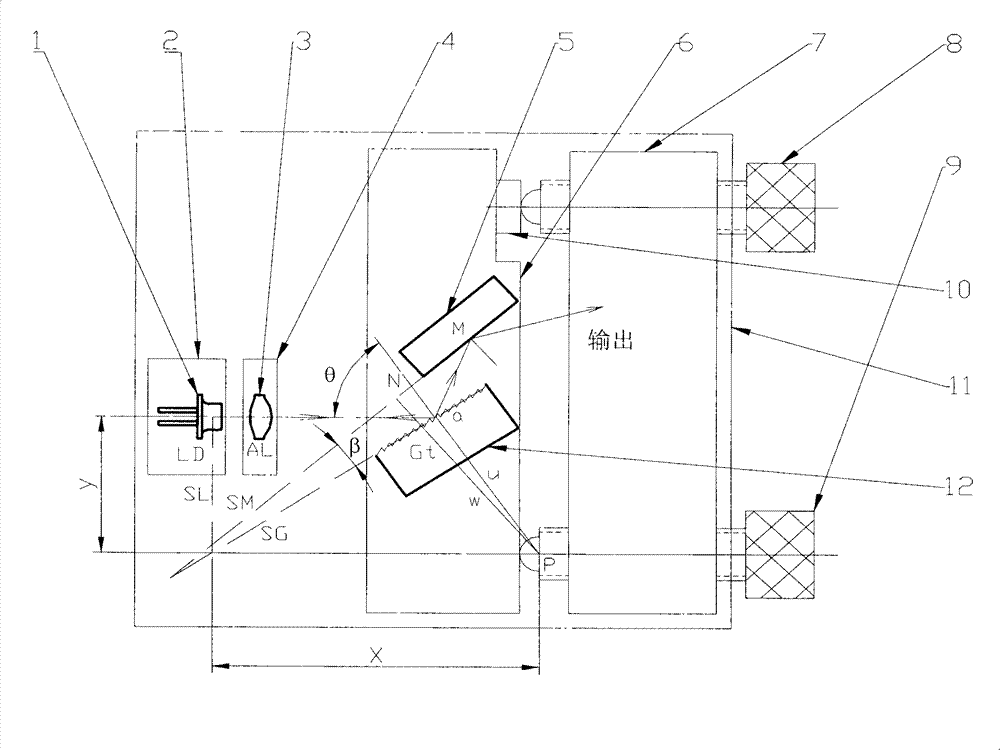

[0028] The Littrow structure external cavity semiconductor laser structure of an embodiment of the present invention is as figure 2 shown. It includes: a semiconductor laser tube 1, a collimator lens 3, a diffraction grating 12 and a deflection mirror 5. The diffraction grating 12 and the deflection mirror 5 are integrated and can rotate around the quasi-synchronous frequency tuning rotation center Pq of the grating together to realize laser frequency tuning.

[0029] The laser light emitted by the semiconductor laser tube 1 is collimated by the aspheric collimating lens 3 and then incident on the diffraction grating 12 . The first-order diffracted light of the diffraction grating 12 and the incident light collinearly reverse along the original path and return to the semiconductor laser tube 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com